Enzymatic pretreatment for making dried fruits

A technology of enzyme treatment and pretreatment, applied in food preparation, application, preservation of fruits/vegetables by dehydration, etc., can solve problems such as microbial deterioration and fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1: Pretreatment of grapes with polygalacturonase

[0081] 100 g of grapes (green grapes originating in China) were added to the following 5 beakers.

[0082] Group 1: 100 g of grapes were added to 200 ml of NaOH solution with a NaOH concentration of 15 g / l and a solution pH of 13.0.

[0083] Group 2: 100 g of grapes were added to 200 ml of citrate buffer (pH 4.0, 50 mM).

[0084] Group 3: Prepare 200 ml of a stock solution of 0.2% (w / w) low PG concentration citrate buffer (pH 4.0, 50 mM). To this solution was added 100 g of grapes.

[0085]Group 4: Prepare 200 ml of a stock solution (pH 4.0, 50 mM) of citrate buffer with a high PG concentration of 0.4% (w / w). To this solution was added 100 g of grapes.

[0086] Grapes from groups 2, 3 and 4 were macerated for 30 minutes at 50°C. According to the industrial raisin production process, the grapes in group 1 were soaked at room temperature for 30 seconds. All grapes were then removed from the beakers, dried ...

Embodiment 2

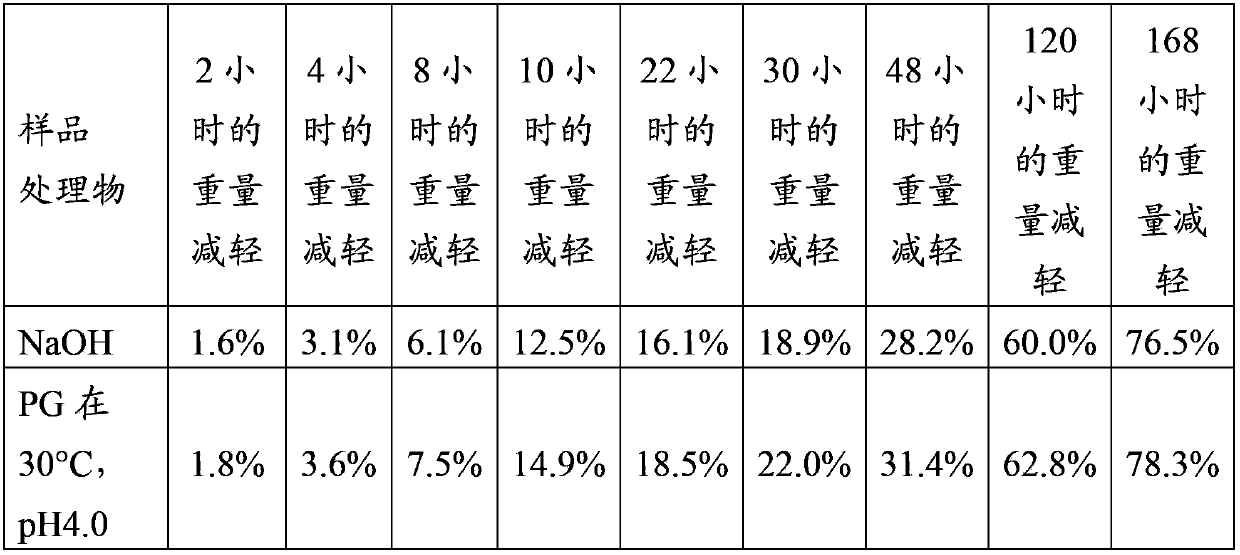

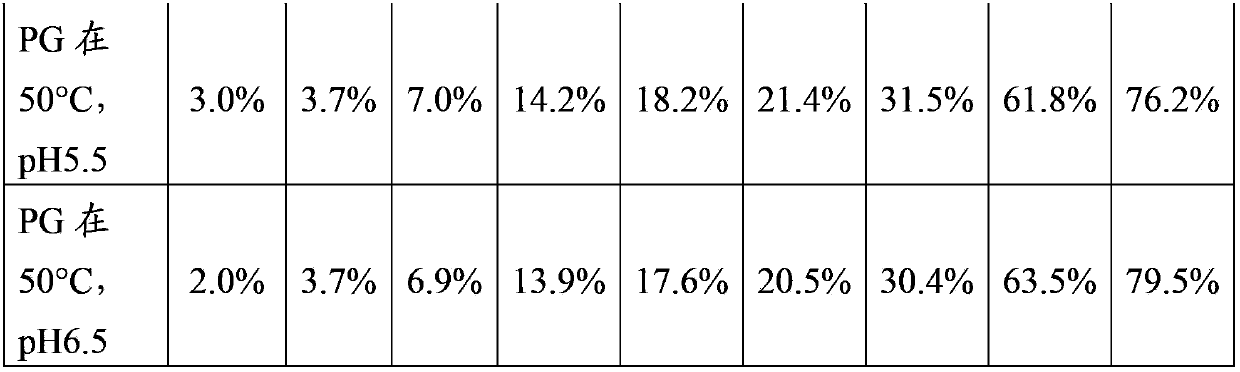

[0091] Example 2: Pretreatment of grapes with polygalacturonase at different pH and temperature

[0092] 100 g of grapes (purple grapes from China) were added to the following four beakers.

[0093] Group 1: 100 g of grapes were added to 200 ml of NaOH solution with a concentration of 15 g / l.

[0094] Group 2: Prepare 200 ml of a stock solution of citrate buffer (pH 4.0, 50 mM) at a PG concentration of 0.2% (w / w). To this solution was added 100 g of grapes.

[0095] Group 3: Prepare 200 ml of a stock solution of citrate buffer (pH 5.5, 50 mM) at a PG concentration of 0.2% (w / w). To this solution was added 100 g of grapes.

[0096] Group 4: Prepare 200 ml of a stock solution of citrate buffer (pH 6.5, 50 mM) at a PG concentration of 0.2% (w / w). To this solution was added 100 g of grapes.

[0097] The grapes in Group 2 were macerated at 30°C for 30 minutes, and the grapes in Groups 3 and 4 were macerated at 50°C for 30 minutes. The grapes of Group 1 were soaked for 30 se...

Embodiment 3

[0102] Example 3: Pretreatment of grapes with polygalacturonase and pectinesterase

[0103] 100 g of grapes (purple grapes originating in China) were added to the following 2 beakers.

[0104] Group 1: 100 g of grapes were added to 200 ml of NaOH solution with a concentration of 15 g / l.

[0105] Group 2: Prepare 200 ml of a stock solution (pH 4.0, 50 mM) of citrate buffer with a PG concentration of 0.15% (w / w) and a PE concentration of 0.05% (w / w). To this solution was added 100 g of grapes.

[0106] The grapes in Group 2 were soaked for 30 minutes at 50°C. The grapes of Group 1 were soaked for 30 seconds at room temperature following the industrial process for raisin production. All grapes were then removed from the beakers, dried in an oven at 45°C, and weighed at intervals of several hours to determine weight loss. The weight loss results are given in Table 3.

[0107] Table 3: Weight loss during drying

[0108]

[0109]

[0110] For the grapes treated with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com