Electromagnetic device employing homopolar opposite magnetic set

A technology of an electromagnetic device and a magnetic group, which is applied in the electromagnetic field, can solve the problems of increasing power loss, reducing magnetic force, and large starting current, and achieves the effects of increasing volume and weight, increasing operating speed, and improving power generation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1 Disk-type electromagnetic device with the same diameter

[0082] like Figure 8 , Figure 9 and Figure 10 As shown, the electromagnetic device 20 is composed of at least one coil disc 21 and at least two magnetic discs 22 arranged at intervals, that is, the coil discs 21 and the magnetic discs 22 are arranged in a staggered interval, and the outer edges of the coil discs 21 utilize a The fixed seat 23 is fixed, and a rotating shaft 24 is jointly pierced between the coil discs 21 and the axle centers of the magnetic discs 22, and the rotating shaft 24 can be pivoted with the coil discs 21 and can drive the magnets. The discs 22 rotate synchronously, so that the coil discs 21 are defined as the stator of the electromagnetic device 20, and the magnetic discs 22 are defined as the rotor of the electromagnetic device 20, and the coil discs 21 are provided with at least one coil 25, which is formed with at least one through-hole groove 210 on the coil disk 21...

Embodiment 2

[0083] Embodiment 2 Concentric disk electromagnetic device with different diameters

[0084] The coils 25A, 25B of the coil disk 21 of the electromagnetic device 20 and the opposite magnets 26A, 26B of the magnetic disk 22 are distributed concentrically with corresponding different diameters [such as Figure 11 Shown]. In addition, the opposite magnets 26A, 26B of the two magnetic disks 22 of the electromagnetic device 20 are distributed concentrically with corresponding different diameters, and the coil 25 on the coil disk 21 can synchronize the concentric magnets 26A, 26B of the corresponding magnetic disk 22 with different diameters. 26B [such as Figure 12 As shown], or the coils 25A and 25B on the coil disk 21 of the electromagnetic device 20 are distributed concentrically with different diameters, and the opposite magnets 26 of the magnetic disks 22 on both sides can synchronize the corresponding coils with different diameters and concentric coils on the coil disk 21 2...

Embodiment 3

[0085] Embodiment 3 multi-layer disk electromagnetic device

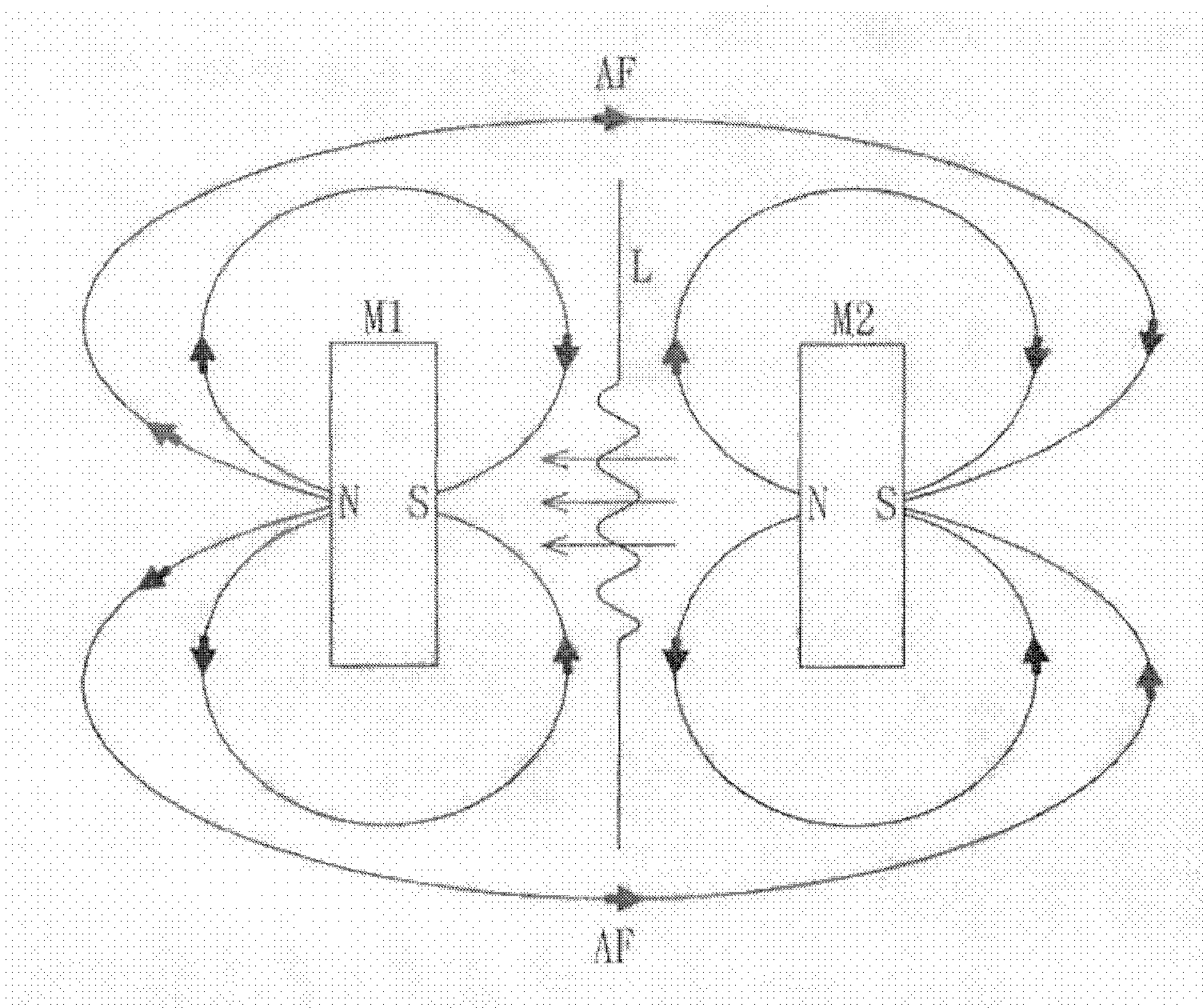

[0086] The electromagnetic device 20 has a plurality of coil disks 21 1 ~21 n and a plurality of magnetic discs 22 arranged at intervals 1 ~22 n+1 composed of [such as Figure 13 Shown], moreover the coil discs 21 1 ~21 n is provided with at least one coil 25 1 ~25 n , and the disks 22 1 ~22 n+1 In the corresponding coil plate 21 1 ~21 n Coil 25 1 ~25 n The same radial direction [such as Figure 10 Shown] or different diameter opposite [such as Figure 11 , Figure 12 Shown] is provided with at least one magnet 26 1 ~26 n+1 , where the magnetic poles of M1 and M3 are in the same direction, and they are both opposite to M2, so as to generate two magnetic channels, and so on, then n+1 magnetic disks can generate n magnetic channels, so there is a significant saving The hardware cost can obtain the advantage of great motor benefit, which can further improve the performance of magnetic cutting, and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com