Cutting anti-blocking device

A technology of anti-blocking and adjusting devices, which is applied to shovels, plows, agricultural machinery and implements, etc., can solve the problems affecting the popularization of no-tillage seeders and the development and promotion of conservation tillage, restricting the promotion and development of conservation tillage, stubble cutting To avoid problems such as large resistance and power consumption, to achieve the effect of improving the efficiency and probability of stubble cutting, improving the efficiency of stubble breaking, and increasing the number of cutting times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

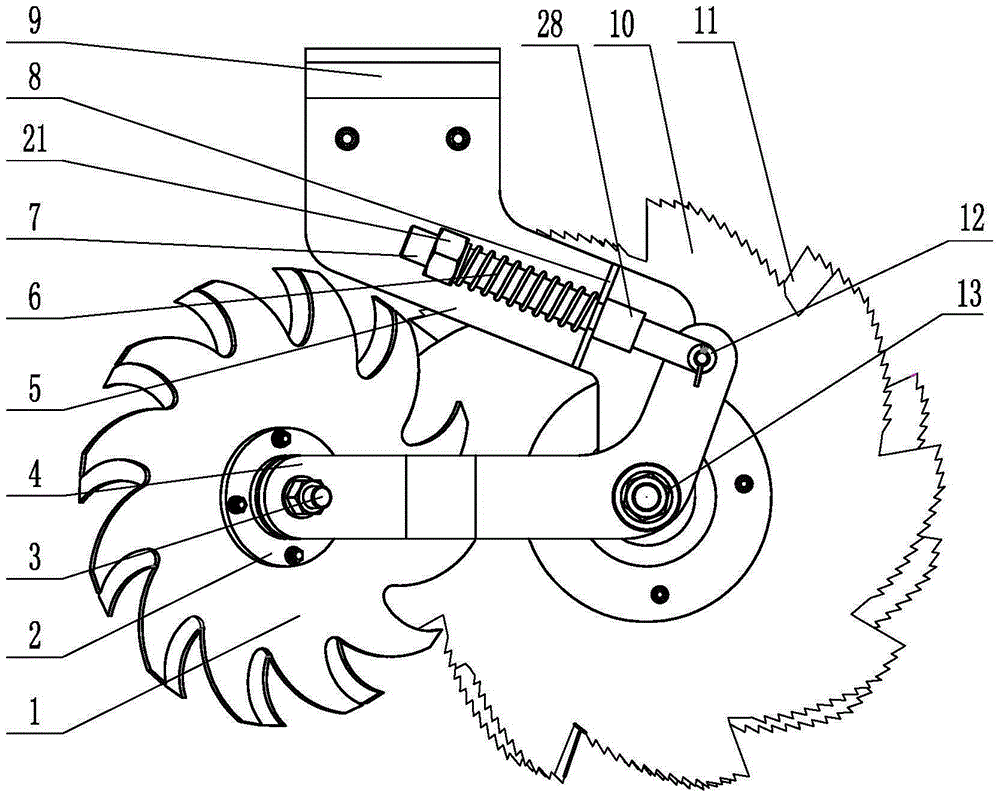

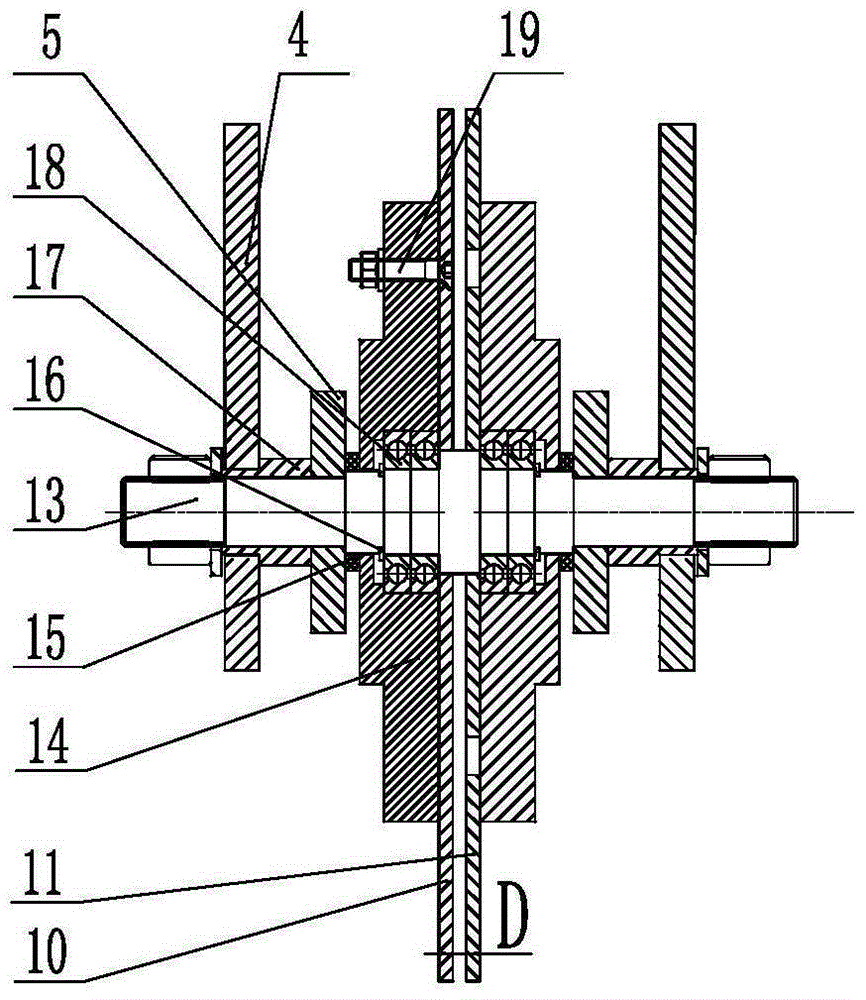

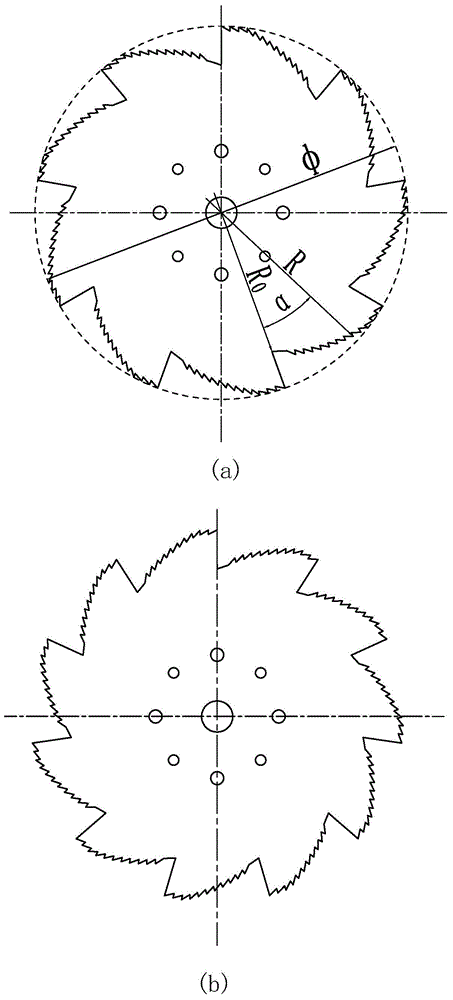

[0037] Embodiment 1: as figure 1 , image 3 As shown, the present invention comprises main shaft 13, sleeve plate 5, slant plate 4, breaker device and stubble removal anti-blockage device, and described breaker device is installed in the middle part of main shaft 13, and stubble removal anti-blockage device is two groups, is symmetrical to the breaker. The cutting device is connected to both ends of the main shaft 13, and the stubble picking wheel 1 of the stubble picking and anti-blocking device is set at an angle with the sawtooth knife of the cutting device, so that the two symmetrical stubble picking wheels 1 are opened in the shape of "eight". The stubble wheel 1 is installed on both sides of the end of the sawtooth knife of the cutting disc, and the stubble wheel 1 can simultaneously move backwards and push the stubble, straw and weeds sideways; the sleeve plate 5 is symmetrically connected to the main shaft 13. Between the stubble and anti-blocking devices, and respect...

Embodiment 2

[0049] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the two cutting disc serrated knives used in this example are disc knives with 7-tooth and 8-tooth helical blades respectively, and the installation distance D is 1mm. The edge angles of the two sides of the disc cutter with two notches are 25°. The diameter φ of the cutting disk spiral blade is 460mm, and the installation angle θ between the stubble picking wheel 1 and the cutting disc sawtooth knife is 35°. During work, the stubble picking wheel 1 and the cutting disc The horizontal distance between the serrated knives is 5cm. The edge angle of the helical blade both sides of the stubble picking wheel 1 is 25 °.

Embodiment 3

[0050] Embodiment 3: The difference between this example and Embodiment 1 is that the two broken disc serrated knives described in this example respectively adopt disc knives with 10 teeth and 13 teeth Archimedes spiral blades, and the installation distance D is 2mm. The edge angles of the two sides of the disc cutter with two notches are 22°. The diameter φ of the helical blade of the broken disc sawtooth knife is 430mm, and the installation angle θ between the described stubble picking wheel 1 and the broken cutting disc sawtooth knife is 33°. The horizontal distance between the disc serrated knives is 4cm. The edge angle of the helical blade both sides of the stubble picking wheel 1 is 23 °.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com