Device for measuring density of cryogenic fluid

A low-temperature fluid density and measuring device technology, applied to measuring devices, specific gravity measurement, instruments, etc., can solve the problems of complex structure, limited temperature and pressure range, high requirements for liquid oxygen sampling, etc., to achieve convenient operation and reliable Effects with strong repeatability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The conception, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose and characteristics of the present invention.

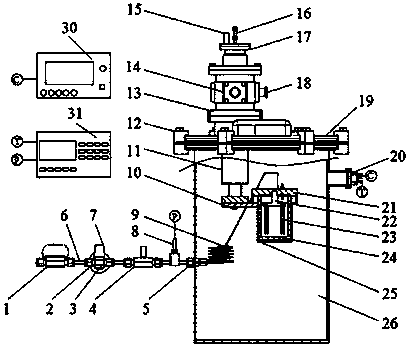

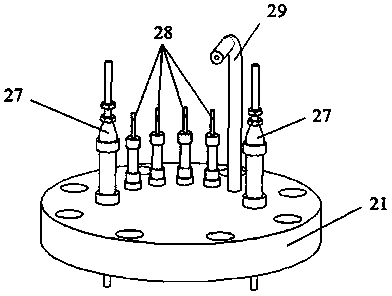

[0023] see first figure 1 and figure 2 , figure 1 It is a structural schematic diagram of an embodiment of the cryogenic fluid density measuring device of the present invention, figure 2 It is a structural schematic diagram of the embodiment of the flange cover of the sample bottle. As can be seen from the figure, the cryogenic fluid density measuring device of the present invention comprises a gas charging and discharging gas connection pipeline, a vacuum housing 26 and a vacuum housing flange 19, a sample bottle 24 and a sample bottle flange cover 21, a capacitive density sensor 23, a guide Cold base 25, temperature measurement and control system and pressure measurement system:

[0024] The charging and discharging gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com