Precast prestressed steel girder with post-seismic restorable function

A recovery function and prestressing technology, applied in the direction of earthquake resistance, joists, girders, etc., can solve problems that hinder the application of steel frame structure systems with recoverable functions, increase the difficulty of steel frame construction, and prolong the construction time of steel frames, so as to improve the construction efficiency. Quality, convenient construction, and the effect of reducing construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

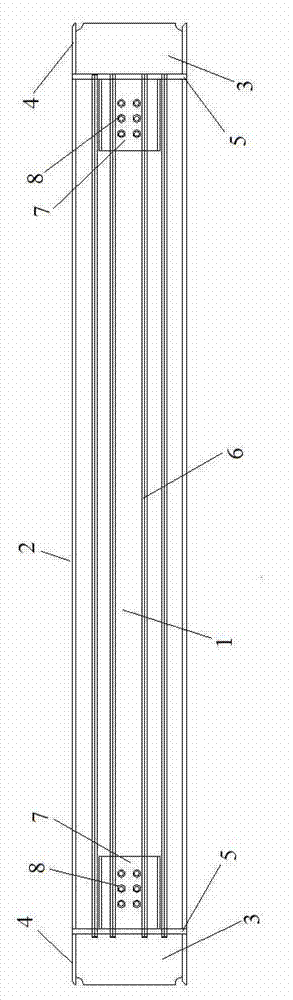

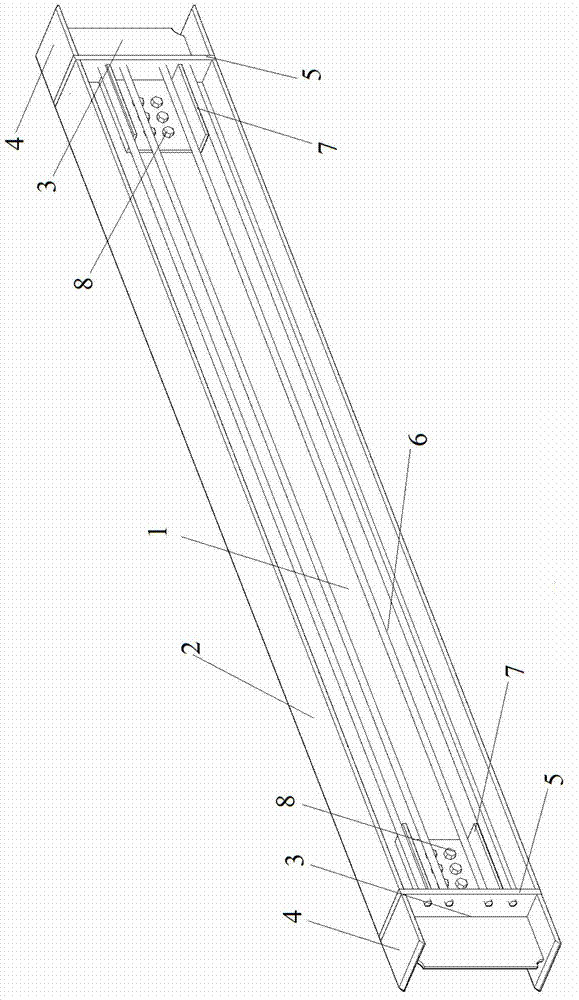

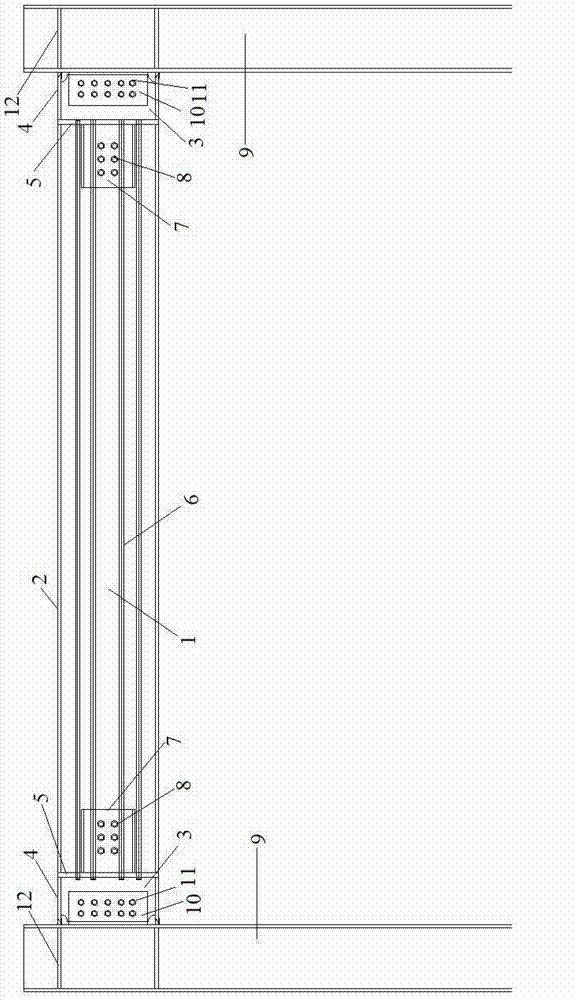

[0031] Such as Figure 1-9 As shown, a prefabricated prestressed steel beam with recoverable function after an earthquake of the present invention includes a middle beam section, short beam sections at both ends, a connecting device and an energy dissipation device, and the middle beam section includes a middle beam section web 1 and the middle beam section flange 2; the short beam section includes a short beam section web 3 and a short beam section flange 4; the connecting device refers to a connecting device between the middle beam section and two short beam sections, including connecting risers 5, Prestressed cable 6; the energy dissipation device includes two channel steels 7 and high-strength bolts 8 (see attached figure 1 ).

[0032] The installation process of the prefabricated prestressed steel girder in the factory is as follows:

[0033] 1) Weld one side of the connecting vertical plate 5 with the web 3 of the short beam section and the flange 4 of the short beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com