Hydrothermal preparation method of TiO2-rGO composite photochemical catalyst

A catalyst and composite light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effect of improving effective separation efficiency, low equipment requirements, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] TiO 2 -rGO composite photocatalyst was prepared as follows: (1) 0.5 g commercial P25 TiO 2 After pretreatment at 550°C for 2 h; (2) dissolving graphene oxide in deionized water and ultrasonic treatment to form a uniform graphene oxide (GO) solution, in which the concentration of graphene oxide was 0.05 wt %; (3) adding 0.5 g pretreated TiO 2 Disperse into 10 ml graphene oxide solution and stir for 2 h to form stable TiO 2 -GO suspension; (4) TiO prepared above 2 -GO suspension was hydrothermally treated at 150°C for 5 h; the obtained product was washed three times and then dried in vacuum at 60°C for 6 h to obtain TiO 2 -rGO composite photocatalyst.

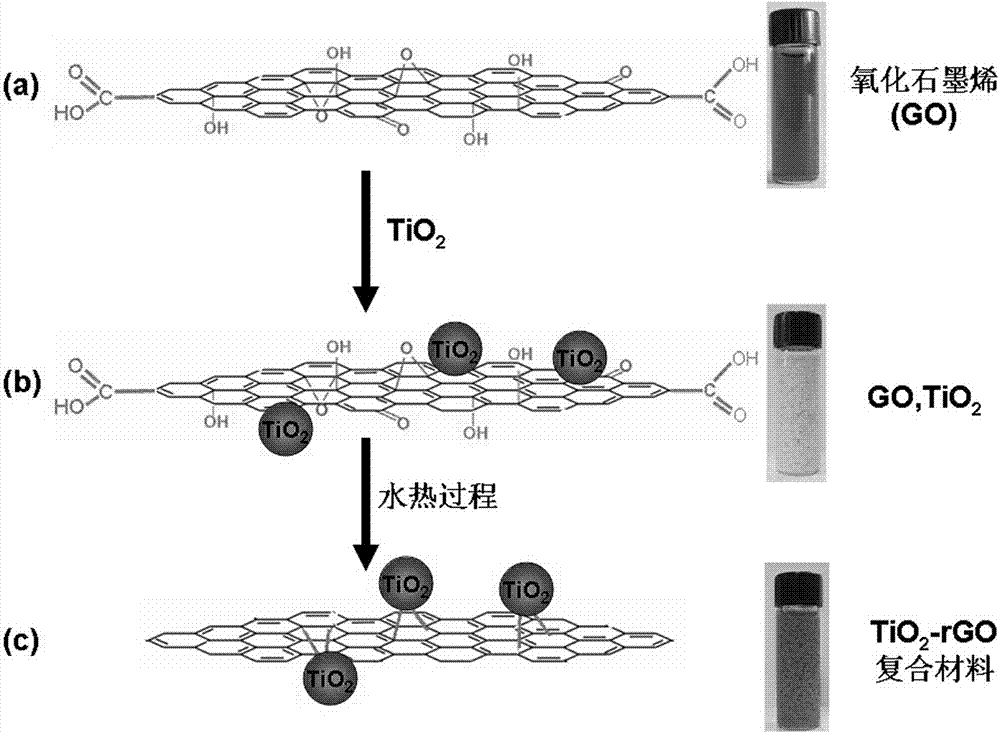

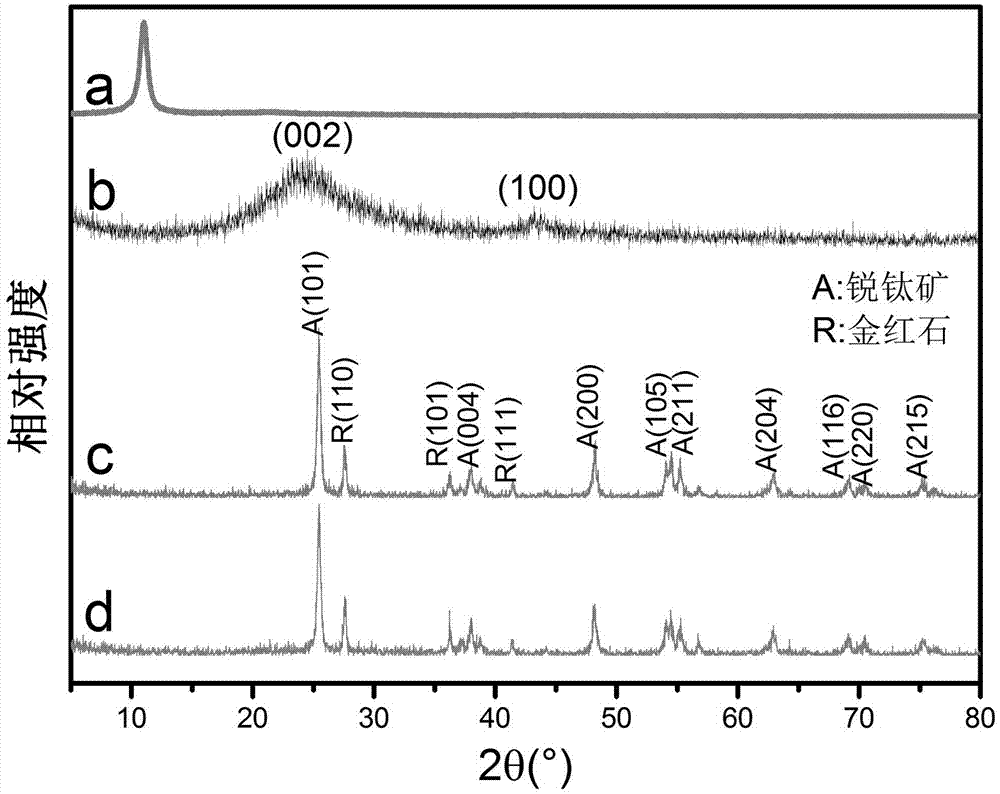

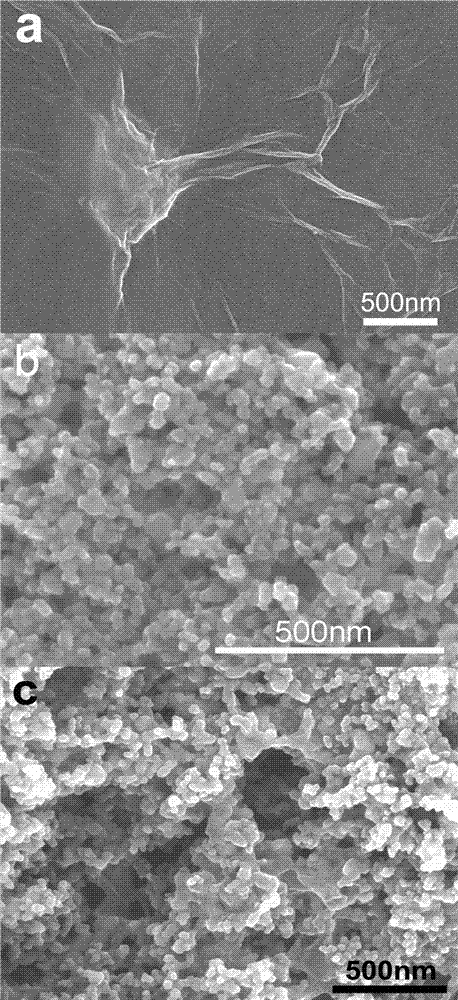

[0030] figure 1 is TiO 2 -Schematic diagram of the synthesis of rGO composites. As we all know, since graphene oxide contains many oxygen-containing functional groups, such as -OH, C=O, C-O-C and -COOH, it can be well dispersed in water to form a uniform and stable solution. figure 1 a is a schematic diagram of the s...

Embodiment 2

[0038] In order to test TiO 2 Effect of powder pretreatment temperature on TiO 2 - Influence of rGO nanocomposites, in addition to different pretreatment temperature, other reaction conditions are as follows: TiO 2 Powder pretreatment time (2 h), TiO 2 Powder mass (0.5 g), graphene oxide concentration (0.05 %) and volume (10 ml), stirring time (2 h), hydrothermal temperature (150 °C), hydrothermal time (5 h), drying temperature (60 °C ), drying time (6 h) etc. are all identical with embodiment 1. The results show that when the pretreatment temperature is 200 °C, TiO 2 The impurities adsorbed on the surface of the powder cannot be effectively removed, and the uniformity and suspension performance are not good after mixing with the graphene solution, which affects the TiO 2 Combination with graphene; when the pretreatment temperature is 350-600°C, TiO 2 The powder is mixed with the graphene solution to obtain a solution with good uniformity and suspension performance; when ...

Embodiment 3

[0040] In order to test TiO 2 Powder pretreatment time on TiO 2 - Influence of rGO nanocomposites, in addition to different pretreatment time, other reaction conditions are as follows: TiO 2 Powder pretreatment temperature (550°C), TiO 2 Powder mass (0.5 g), graphene oxide concentration (0.05 %) and volume (10 ml), stirring time (2 h), hydrothermal temperature (150 °C), hydrothermal time (5 h), drying temperature (60 °C ), drying time (6 h) etc. are all identical with embodiment 1. The results show that when the pretreatment time is 0.5 h, TiO 2 The impurities adsorbed on the powder surface were not effectively removed, which affected the formation of composite materials and the TiO 2 and graphene; when the pretreatment time is 1-3 h, TiO 2 The impurities adsorbed on the powder surface are effectively removed, forming a fresh interface, making TiO 2 It is easy to combine with the graphene surface; when the pretreatment time reaches 5 h, TiO 2 Too large powder particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com