Flue gas desulfurization process and device adopting acetylene sludge-gypsum method

A calcium carbide slag and gypsum process technology, applied in the field of flue gas desulfurization, can solve the problems of the desulfurization device being unable to operate normally, hindering the oxidation of calcium sulfite, and difficulty in the dehydration process of gypsum, so as to prolong the service life, reduce the operation cost and improve the safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

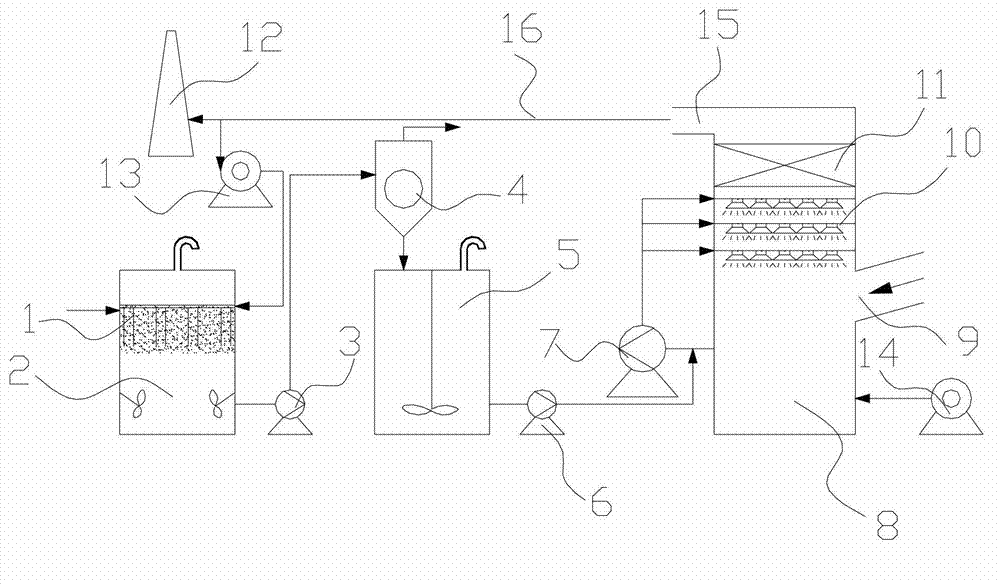

Image

Examples

Embodiment 1

[0040] In a thermal power plant, four 130t / h boilers adopt this desulfurization process. The pH value of the slurry pretreatment tank is controlled at 8.0-9.0. The net flue gas entering the slurry pretreatment tank accounts for 4.3% of the total flue gas volume. The bubbling layer is designed as 0.5 meters, the liquid-gas ratio is 8L / m 3 , The pH value of the absorption tower is controlled between 5.0-5.4. Imported sulfur dioxide concentration is 4800mg / m 3 , the outlet sulfur dioxide concentration is 51mg / m 3 , the purity of gypsum is 98.4%, the moisture content of gypsum is 7.9%, and the content of heavy metal ions in gypsum is 0.01%.

Embodiment 2

[0042] In a thermal power plant, two 220t / h boilers adopt this desulfurization process. The pH value of the slurry pretreatment tank is controlled at 8.2-8.8. The net flue gas entering the slurry pretreatment tank accounts for 3.7% of the total flue gas volume. The bubbling layer is designed as 0.5 meters, the liquid-gas ratio is 9L / m 3 , The pH value of the absorption tower is controlled between 5.2-5.5. Imported sulfur dioxide concentration is 5460mg / m 3 , the outlet sulfur dioxide concentration is 62mg / m 3 , the purity of gypsum is 99.1%, the moisture content of gypsum is 8.3%, and the content of heavy metal ions in gypsum is 0.01%.

Embodiment 3

[0044] A self-owned power plant of an enterprise, 4 sets of 135MW units adopt this desulfurization process, the pH value of the slurry pretreatment tank is controlled at 8.0-8.5, the net flue gas entering the slurry pretreatment tank accounts for 4.6% of the total flue gas volume, the bubble layer design 0.5 meters, the liquid-gas ratio is 9L / m 3 , The pH value of the absorption tower is controlled between 5.1-5.6. Imported sulfur dioxide concentration is 4880mg / m 3 , the outlet sulfur dioxide concentration is 46mg / m 3 , the purity of gypsum is 98.4%, the moisture content of gypsum is 9.2%, and the content of heavy metal ions in gypsum is 0.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com