Sintered magnet and method for producing the same

A technology of sintered magnets and magnets, applied in the manufacture of inductors/transformers/magnets, motor generators, and stator/rotor bodies, etc., can solve the problems of scarcity, high cost, and high manufacturing costs of permanent magnets, and reduce eddy current loss. , the effect of rich shape changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, embodiments of the present invention will be described with reference to the drawings. It should be noted that, of course, the shape of the sintered magnet assembled from the basic magnets is not limited to the illustrated example.

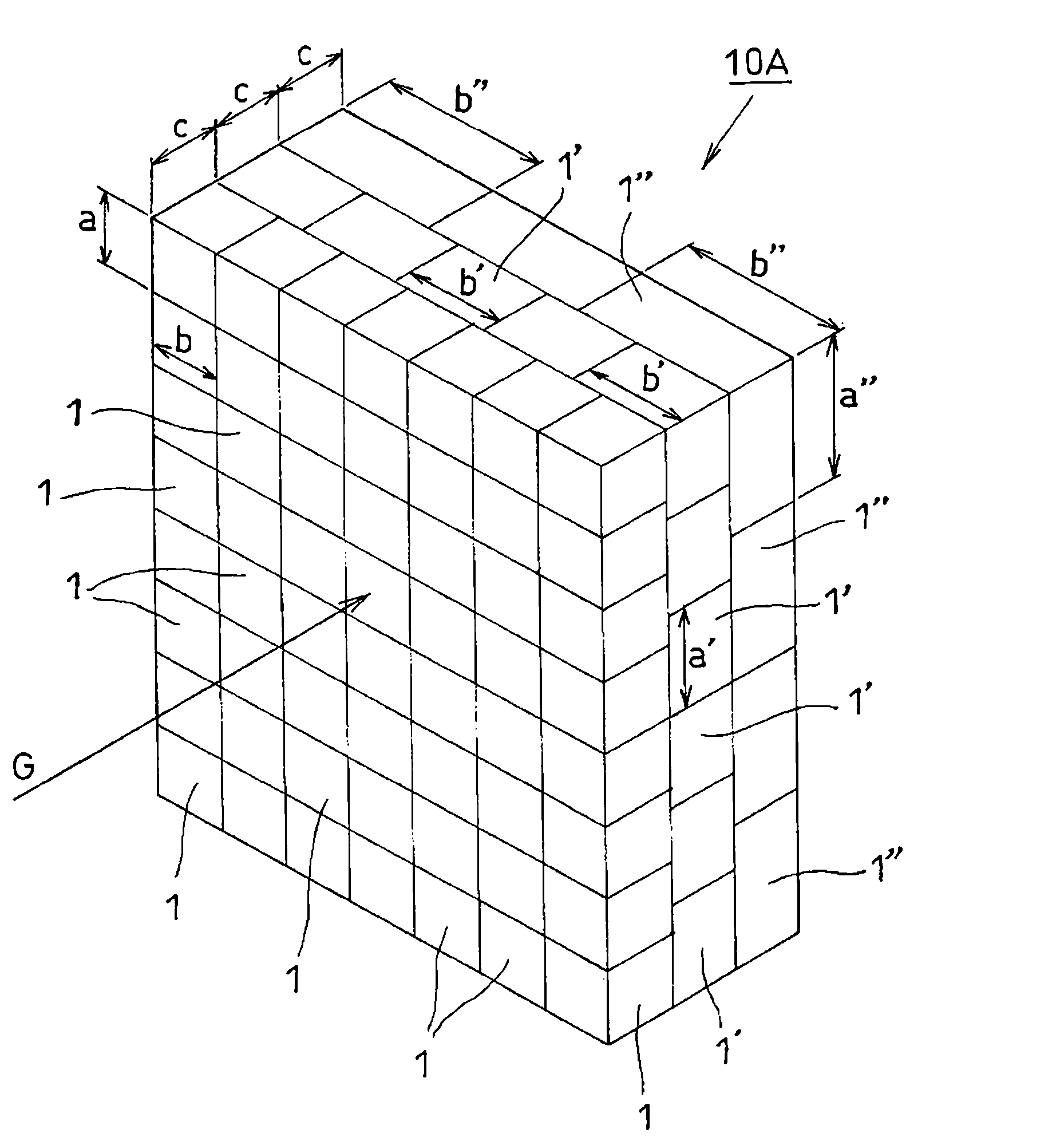

[0047] figure 1 , 3 , 4, and 5 are perspective views illustrating an embodiment of a sintered magnet, respectively.

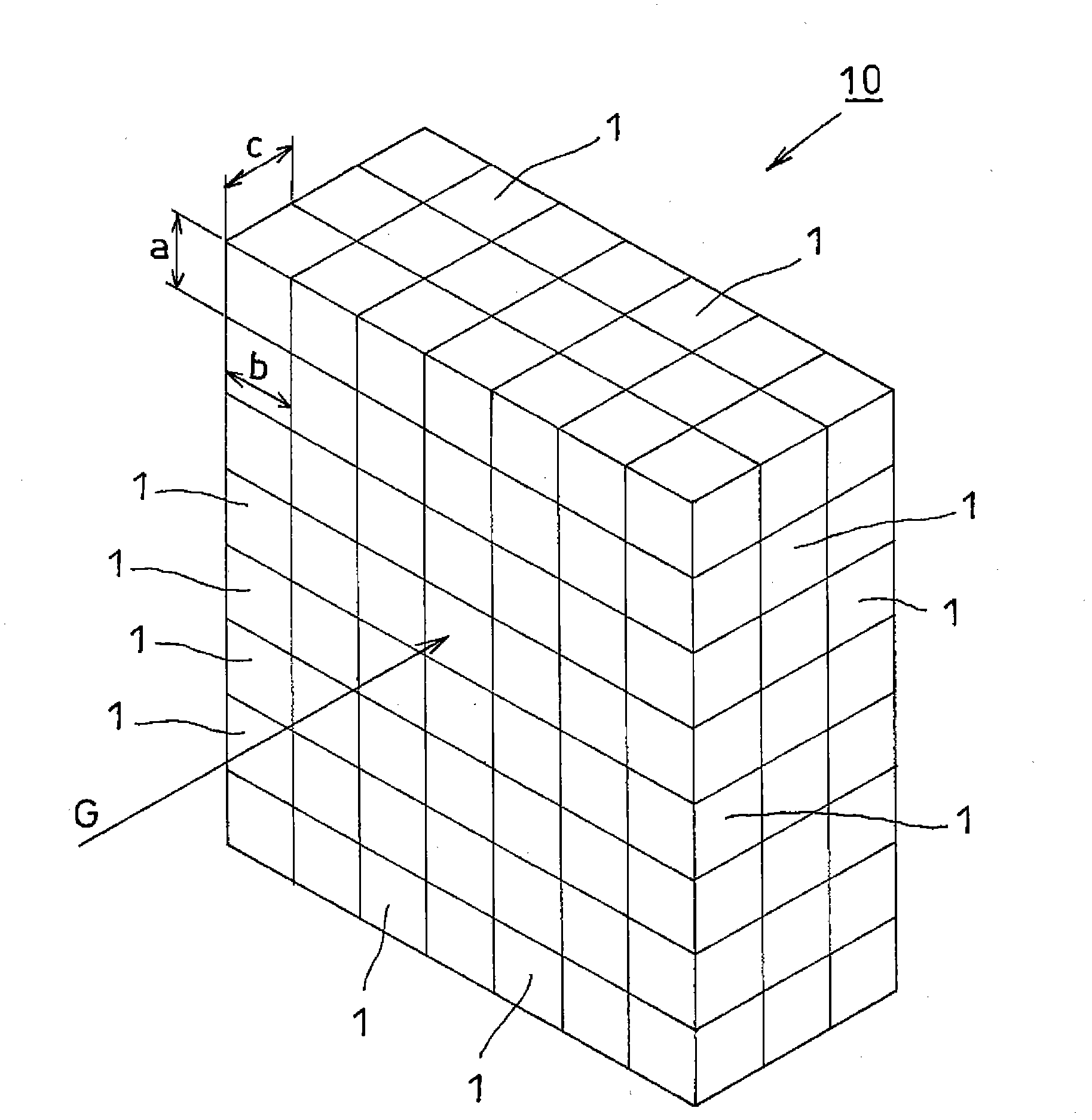

[0048] first, figure 1 The shown sintered magnet 10 is formed from a single basic magnet of the same shape, the length of the longitudinal side: a, the length of the transverse side: b, and the height: c are all cube-shaped basic magnets 1 of the same size in the longitudinal, transverse and height directions A plurality of each is provided in parallel, and the basic magnets 1 and 1 are joined with each other only by the magnetic force they have.

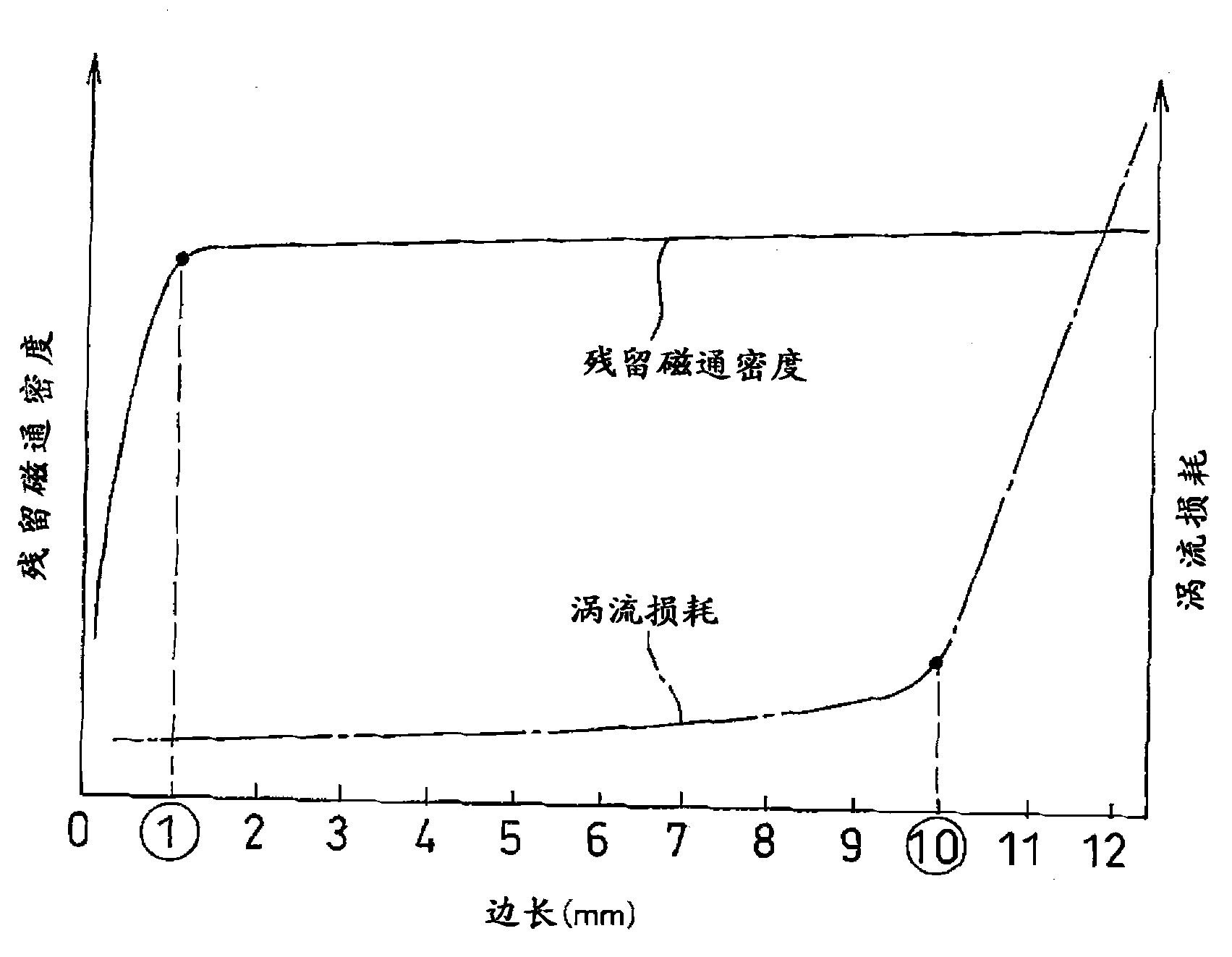

[0049] Here, the side lengths of the basic magnet 1: the lengths of a, b, and c are set within a range of 1 mm to 10 mm. refer to figure 2 The basis for sett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com