Tire for a vehicle carrying heavy loads

A technology for heavy loads and tires, which is applied to heavy tires, heavy vehicles, vehicle parts, etc., and can solve problems such as failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

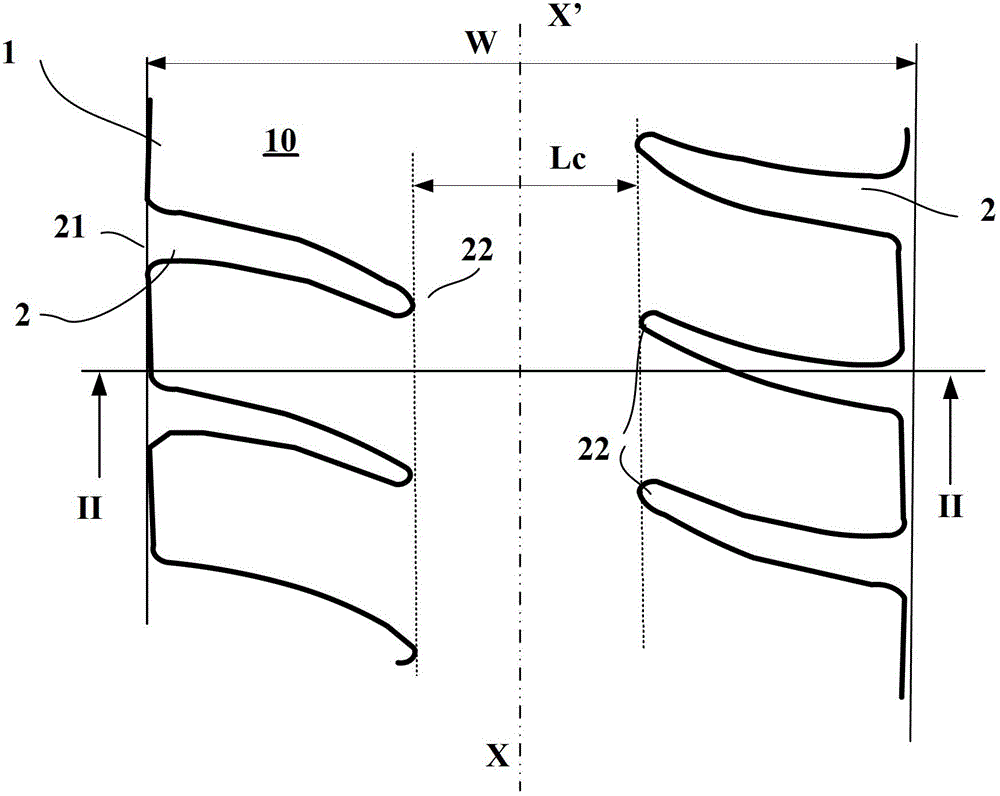

[0034] figure 1 The rolling surface 10 of the tread band 1 of the tire according to the invention is shown. The tread band has an overall width W and has a median plane that divides the tread band substantially into two halves of equal axial width (which is the same as figure 1 The line of intersection of the planes is represented by line XX').

[0035] This tread band 1 comprises, on each side of the median plane XX', a plurality of transverse grooves oriented substantially in the transverse direction (that is to say at an angle of less than 45° to the axis of rotation (the axis whose direction is perpendicular to the direction XX') Slot 2. Each transverse groove 2 has an average depth and two ends 21, 22 of which one, the axially outer end 21, opens to the edge of the tread band and the other, the axially inner end 22 is not open laterally. This inner end 22 is located at a non-zero distance from the median plane. An intermediate portion of width Lc extending axially be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Secant modulus | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com