Method for preparing graphene devices

A graphene and device technology, applied in the field of graphene optical lithography device preparation, can solve the problems of low time efficiency, high cost of electron beam exposure technology, unsuitable for large-scale production, etc., and achieve high production efficiency and good repeatability , Simple and controllable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with the accompanying drawings, the present invention will be further described in detail through examples, but the present invention is not limited in any way.

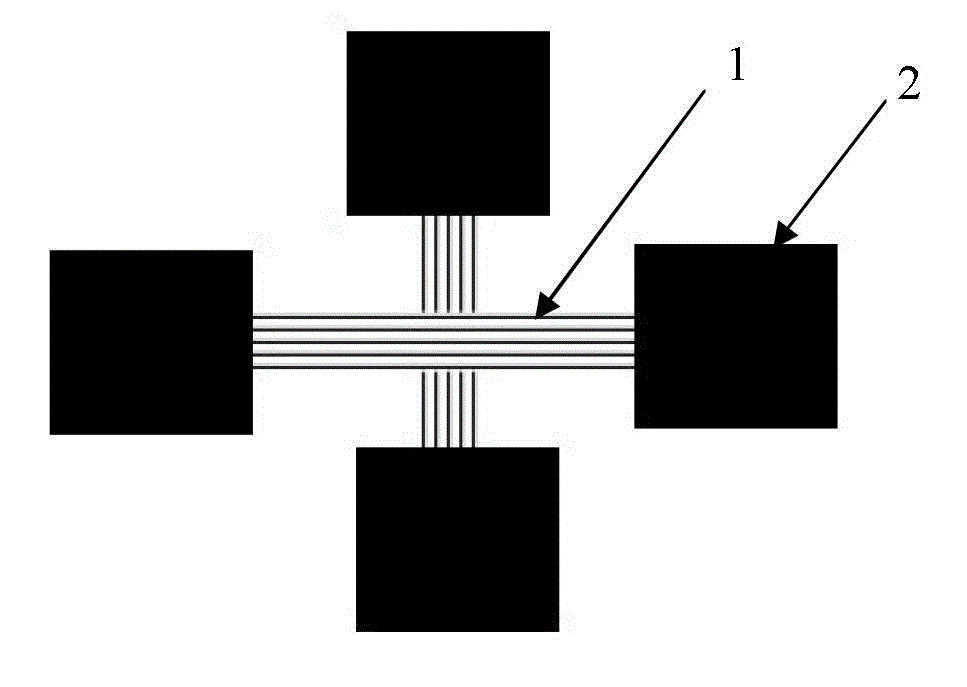

[0027] Such as figure 1 In the graphene lithography device shown, the graphene material as the active region is cross-shaped, the channel 1 is 10 microns long and 2 microns wide, and four electrodes 2 are in contact with the graphene channel 1, and the electrode material is For Ti / Au, you can choose two electrodes and add a bottom gate voltage for field effect measurement. Both the metal layer and the etching layer are patterned using Fuji I-line adhesive 665D. The specific preparation steps of the device are as follows:

[0028] 1. Grow graphene on the metal by chemical vapor deposition, and then transfer the graphene to the insulating substrate;

[0029] 2. The first optical lithography defines the pattern of the electrode on the insulating substrate, and then uses electron beam evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com