Alcohol-base fuel ejecting self-adaptive air distributing burner

A technology of alcohol-based fuel and injector, which is applied in the direction of burner, combustion type, combustion method, etc., can solve the problems of reduced combustion efficiency, complex structure of the burner, poor automatic adjustment ability, etc., and achieves simple structure and optional power Wide range, stable combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

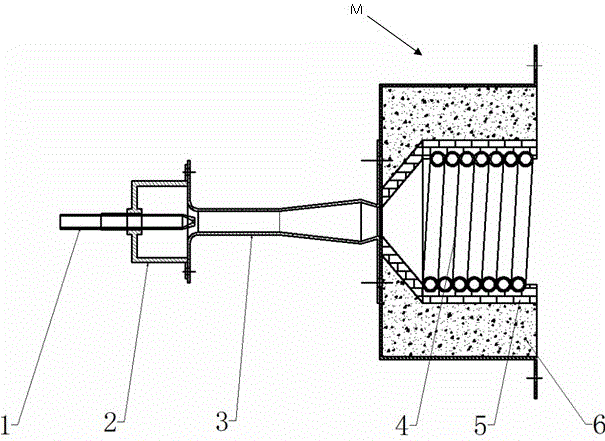

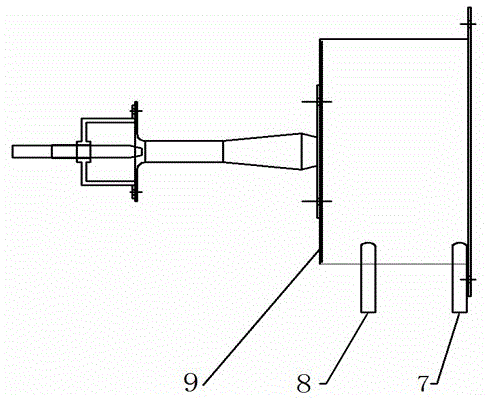

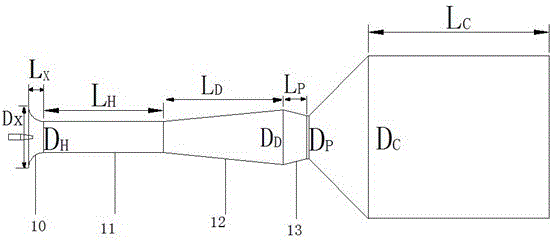

[0025] An alcohol-based fuel-injection self-adaptive air distribution burner, the main purpose is to vaporize the liquid alcohol-based fuel through heating, use the fuel that has become a gaseous fuel to inject the air that is completely required to mix it, and then pass it into the combustion chamber. Combustion in the ember chamber, which has fuel nozzle 1, nozzle bracket 2, ejector 3, spiral vaporizer 4, refractory material 5, heat insulation material 6, gas fuel outlet 7, liquid fuel inlet 8, ember chamber 9, The suction section 10 of the ejector 3, the ejector mixing section 11, the ejector diffuser section 12, and the ejector contraction section 13.

[0026] See 1-3, an alcohol-based fuel-injection self-adaptive air distribution burner, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com