Floating type water nozzle

A floating and faucet technology, applied in valve lifts, shaft seals, valve details, etc., can solve the problems of seal leakage, waste of water resources and economic losses, insurmountable valve seat sealing performance, etc., to reduce manufacturing costs, The effect of prolonging the service life and improving the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

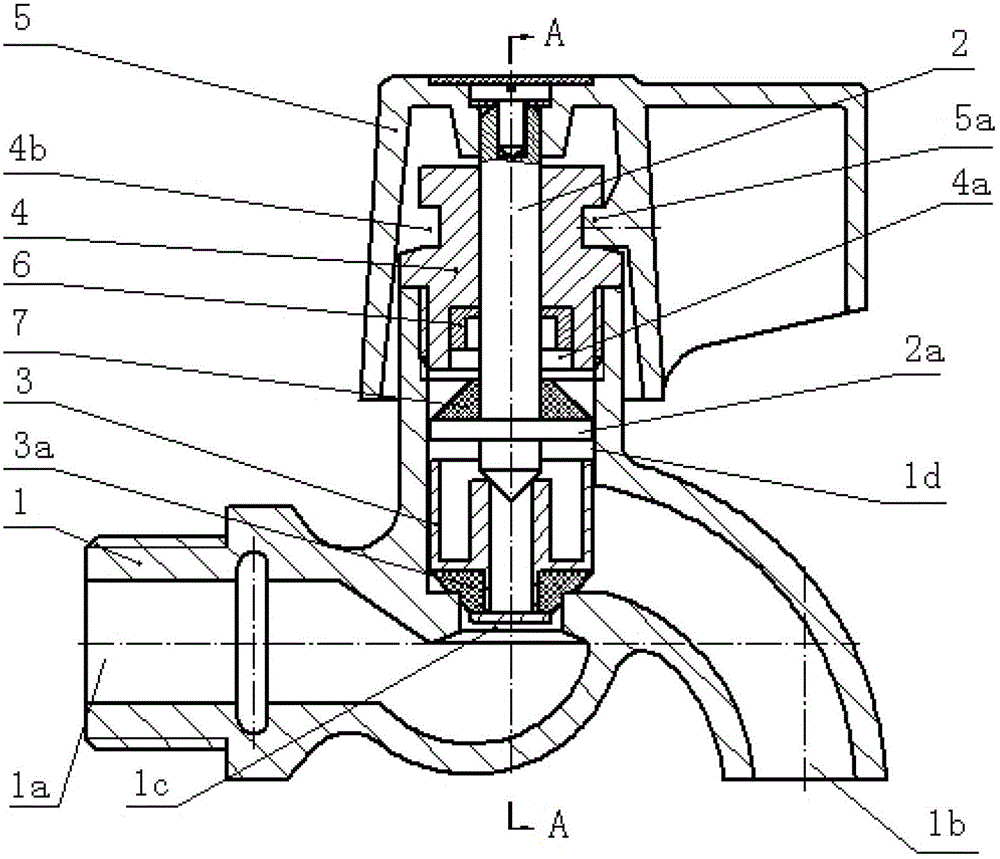

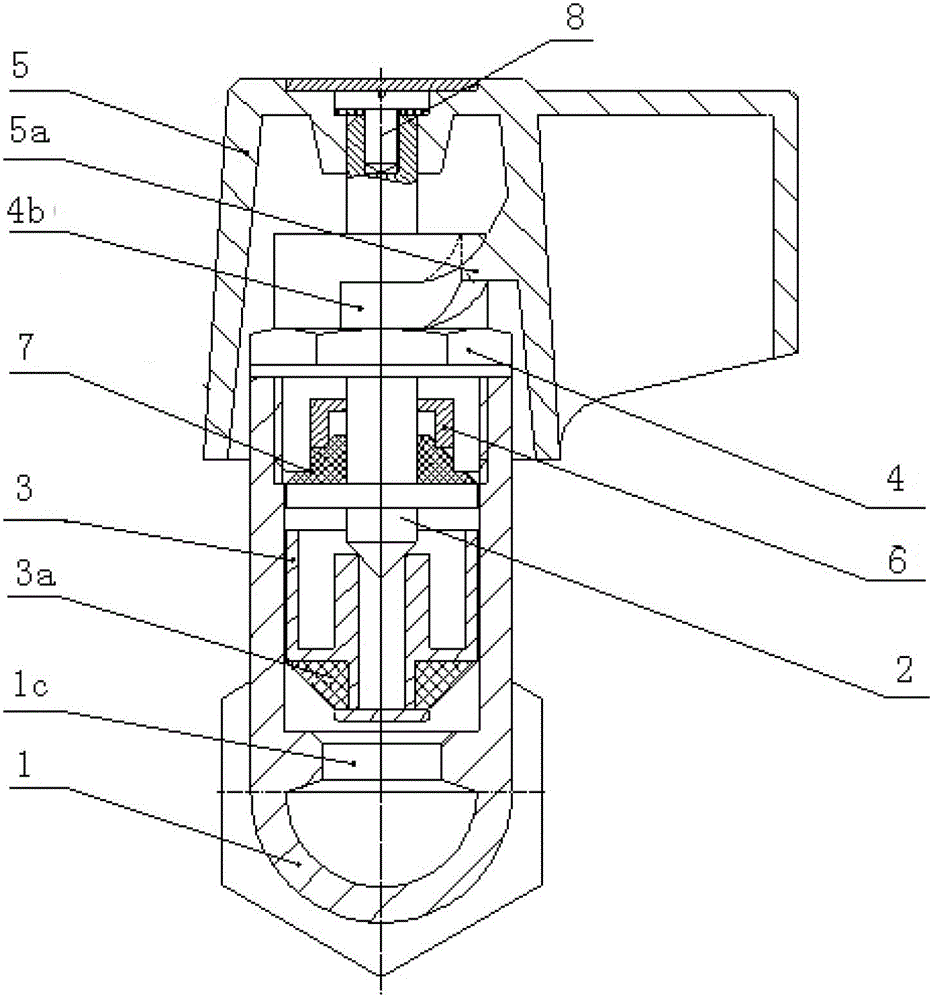

[0022] The following is a detailed description of the specific implementation of the new floating cold water nozzle according to the accompanying drawings:

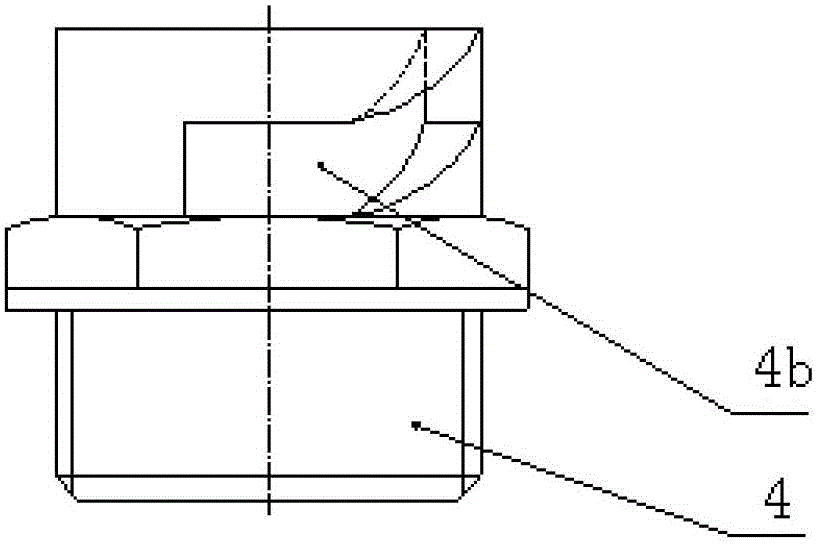

[0023] figure 1 , figure 2 A floating faucet of the present invention is given, including a valve body 1, a valve stem 2, a valve core assembly 3, a valve cover 4, and a handle cover 5. The valve body 1 includes a water inlet 1a, a water outlet 1b, and a valve cavity 1d , the switch control port 1c between the water inlet 1a and the water outlet 1b is at the bottom of the valve chamber 1d, the valve core assembly 3 includes a floating plug 3a, and the floating plug 3a is placed at the bottom of the valve chamber 1d in the valve body 1, and the valve chamber 1d There is a gap fit, the upper part of the floating plug 3a has a central blind hole coaxial with the valve stem 2, the lower part of the floating plug 3a is installed with a conical lower gasket 3b, and the conical lower gasket 3b corresponds to the switch control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com