Follow-up drilling machine for sleeve of down-the-hole hammer

A technology of down-the-hole hammer and casing, applied in casing, drill pipe, drill pipe, etc., can solve the problems of uneven force on the column, difficult to separate, increase the weight of one side of the column, etc., so as to save production costs and equipment. The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

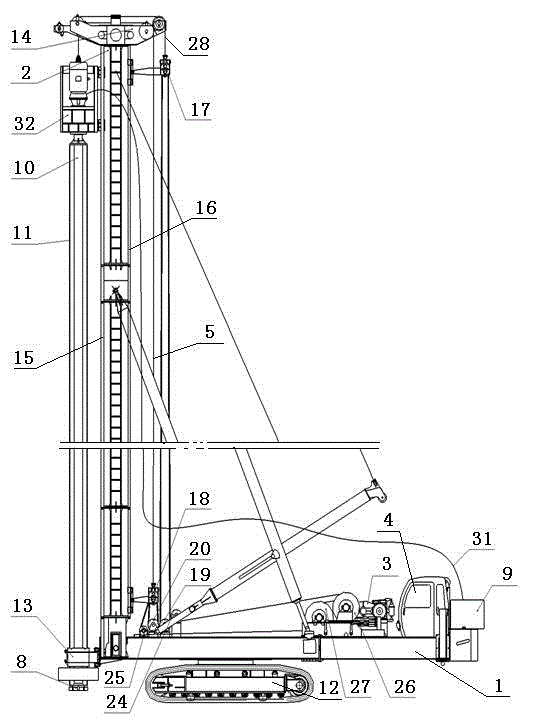

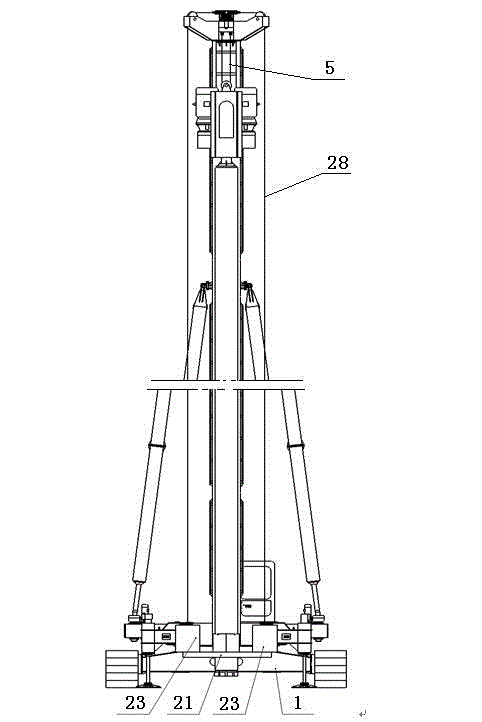

[0021] Below in conjunction with accompanying drawing, the present invention is further described:

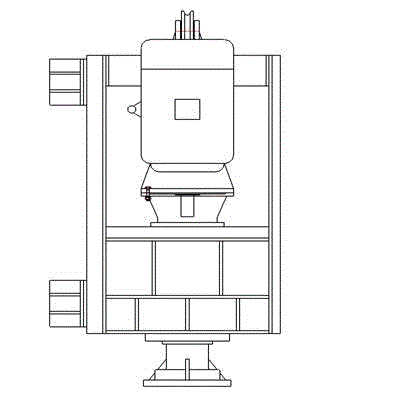

[0022] As shown in the drawings, a DTH hammer casing follow-up drilling rig includes a support machine, an impact device, a vibratory hammer, a drill pipe 10 and a casing 11, and the support machine includes a base 1, a column 2, a hoist 3, and an operating room 4 And steel wire rope 5,28, impact device comprises down-the-hole hammer 8 and air compressor 9, and the structure of down-the-hole hammer 8 is identical with prior art, this does not go into details, drill pipe 10 outside is sleeved with sleeve pipe 11, and base 1 lower end can adopt Crawler-type traveling device 12 or walking device 12, crawler-type traveling device 12 or walking device 12 are prior art, this does not go into details, base 1 upper end is provided with winch 3 and operating room 4, and base 1 front end is provided with column 2, The lower part of casing 11 is provided with casing 13, and casing 13 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com