Fiber reinforced composite rib/ cable anchorage

A composite material and fiber-reinforced technology, applied in the field of anchors, can solve the problems of increased production cost, high maintenance cost, compressive stress concentration, etc., to avoid surface stress concentration, reduce later maintenance costs, and improve the rationality of stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

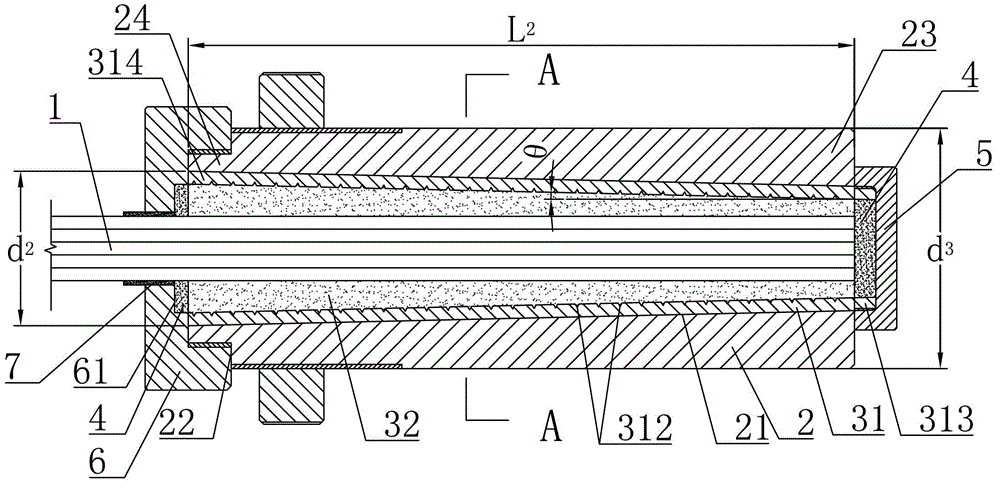

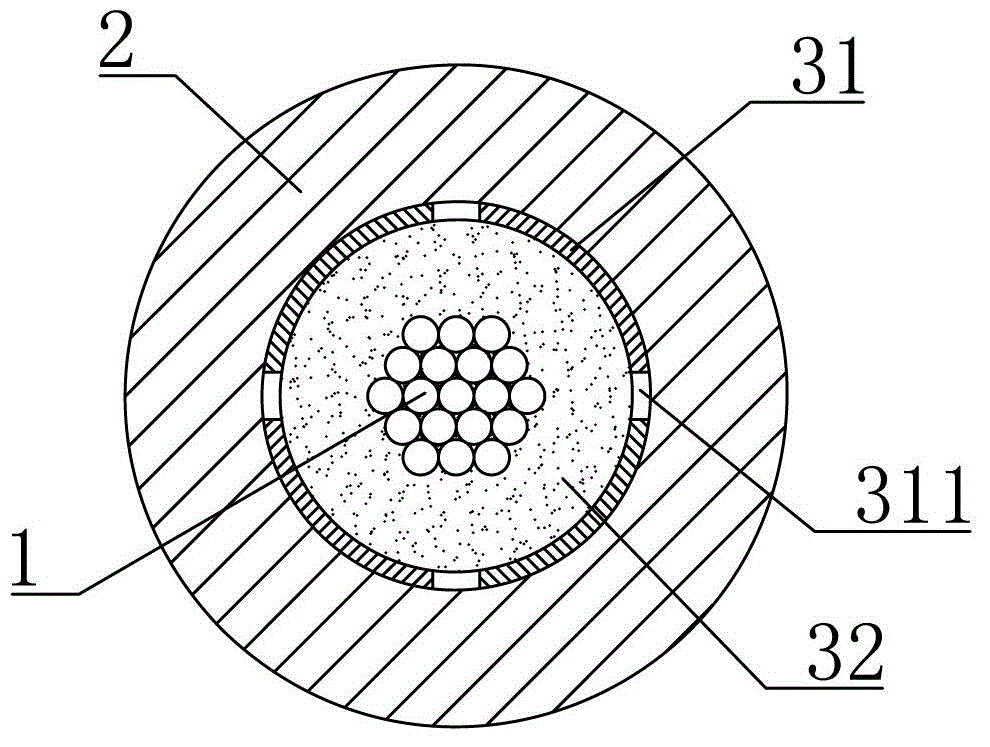

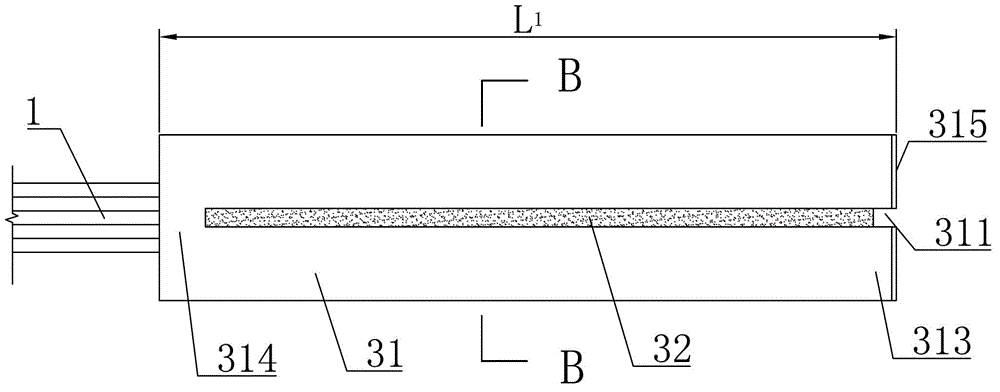

[0021] As shown in the figure, a fiber-reinforced composite material tendon / cable anchor includes an anchor tube 2 for anchoring FRP tendons / cables 1. The anchor tube 2 is coaxially provided with a tapered through hole 21, and the tapered through hole 21 A casing assembly equipped with FRP tendons / cables 1 that is fitted with a tapered through hole 21 is embedded in it. The diameter of the tapered through hole 21 ranges from small to large from the free end 23 of the anchor tube 2 to the loaded end 24. Large distribution, the bushing assembly includes a bushing 31 with four dividing grooves 311 with the same structure along the axial direction, the dividing grooves 311 are evenly distributed on the pipe wall of the bushing 31, and multiple annular The groove 312, the FRP tendon / cable 1 is fixedly arranged in the casing 31 through the bonding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com