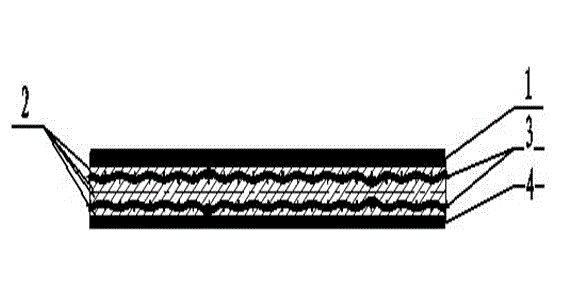

Production process for manufacturing rubber dam bags by using polyester fabric as framework material

A technology for a rubber dam bag and a skeleton material is applied in the production process field of making a rubber dam bag with a polyester fabric as a skeleton material, and can solve the problems of unsolved, unrealizable production process, low chemical activity on the surface of polyester fiber, and the like, Achieve the effect of light weight, good shape retention and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Below in conjunction with accompanying drawing and with dam height dam height 1.6 meters, internal pressure ratio is 1.3 double-anchor formula 29 meters long rubber dam dam bag as embodiment, specifically elaborates the manufacturing process of the present invention:

[0061] A. Pretreatment of polyester fabric:

[0062] Select the PP1010 plain polyester canvas with both warp and weft strength indicators of 100kN / m and soak it in the pretreatment solution of water-soluble epoxy resin and acid curing agent for 100s; the formula ratio is as follows:

[0063] The ratio (mass ratio) of water-soluble epoxy resin WSR618: curing agent WSR905: water is 100:80:300;

[0064] After dipping, the heat treatment temperature of the polyester fabric is kept at 130°C for 150s.

[0065]

[0066] B. Viscosification treatment of polyester fabric:

[0067] Immerse the polyester canvas pretreated in step A in the resorcinol-formaldehyde-latex (RFL) viscosity-increasing treatment solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com