Fibers with characteristics of temperature increasing and heat storage, preparation method and textile thereof

A technology of textiles and fibers, applied in the field of heat-storing fibers and their preparation methods and textiles, can solve problems such as leakage, achieve good heat storage performance, easy industrial production, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

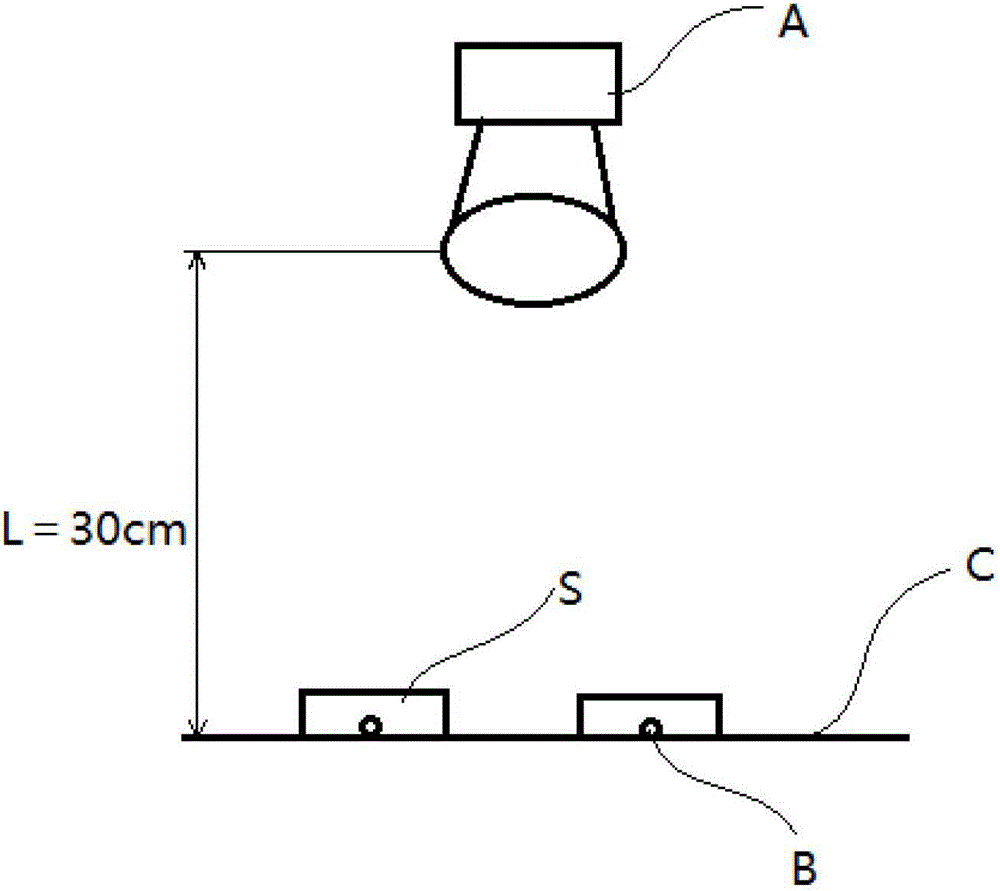

[0030] see figure 1 , which shows a detection example of the heat generation effect of a fiber with temperature rising and heat storage in the present invention.

[0031] Testing Unit: Kinki Office of BOKEN Quality Evaluation Structure of Japanese General Incorporated Foundation

[0032] Quality test report number: 11604789-1

[0033] Test item: temperature measurement, the test method is as follows:

[0034] 1. Test samples

[0035] 1.: fiber of the present invention: for adding the textile fiber that accounts for total weight 2.9% weight part nano-unit in conventional textile fiber, the particle size of this nano-unit is about 300 nanometers; Described micro-particle comprises the zinc of 950 weight units and 500 weight units The aluminum of the unit (or only one of them can be added), and other trace elements, the nano unit of the present invention can be added in the fiber manufacturing process by using any one of the prior art.

[0036] ②: Control fibers: conventional...

Embodiment 2

[0050] The difference between this embodiment and the above-mentioned embodiment is that the detection sample is a textile fiber that accounts for 0.2% by weight of the nano-units of the total weight in conventional textile fibers, and the particle size of the nano-units is about 8000 nanometers; the micro-particles Comprising 420 weight units of aluminum and 495 weight units of iron, the nano-units of the present invention can be added in the fiber manufacturing process using any of the prior art.

[0051] For example: this embodiment has adopted a kind of preparation method of the textile fiber that heats up rapidly and heat storage when encountering light, comprises the following steps: A, natural macromolecular substance or inorganic substance (such as: viscose fiber), or synthetic high-molecular substance Molecular substances or inorganic substances (such as: nylon or acrylic fiber) are made into spinning melt or solution; B. Add the above-mentioned nano units in the spinn...

Embodiment 3

[0057] The difference between this embodiment and the above-mentioned embodiment is that the detection sample is a textile fiber that accounts for 1.5% by weight of the nano-units of the total weight in conventional textile fibers, and the particle size of the nano-units is about 4000 nanometers; the micro-particles Including 110 weight units of zinc, 300 weight units of aluminum, and 15 weight units of iron, the nano-units of the present invention can be added in the fiber manufacturing process using any of the prior art.

[0058] For example: this embodiment adopts a preparation method of textile fibers that heat up rapidly when exposed to light and store heat, including the preparation steps of textile fiber chemical fiber masterbatches. During the preparation of chemical fiber masterbatches, the above-mentioned nano units are added, and then produced fiber out. Other process steps of the fiber preparation method in this embodiment are the same as the fiber preparation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com