Method for preparing monochlorotoluene with toluene chloridizing method

A monochlorotoluene, ring chlorination technology, applied in the chemical field, can solve the problems of insufficient selectivity, reduce the total yield of p-chlorotoluene and o-chlorotoluene, and many by-products of m-chlorotoluene, and achieve the goal of improving selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

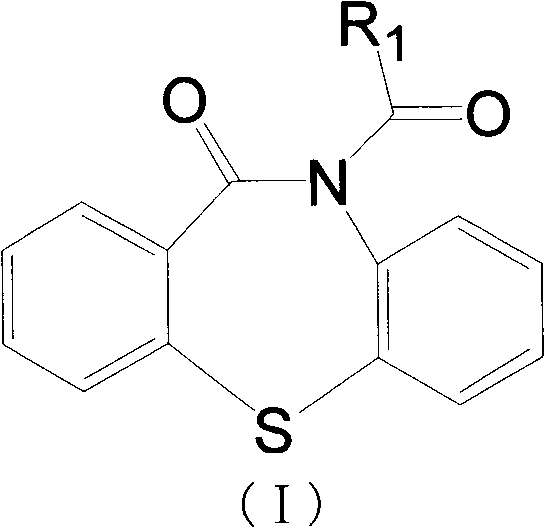

[0018] Take by weighing 30g toluene, iron powder 20mg, auxiliary agent I (R 1 =NHOH) 10 mg, and evenly and slowly pass chlorine gas for 4 hours while stirring in the dark, and the temperature in the whole process is controlled at 0°C. After the reaction is completed, filter, wash with water, dry over anhydrous sodium sulfate, and filter. Sampling was carried out for gas chromatography detection. The toluene conversion rate was 97.2%, the content ratio of p-chlorotoluene and o-chlorotoluene was about 2.1, the content of m-chlorotoluene was 0.12%, and the content of total dichlorobenzene was 0.55%.

Embodiment 2

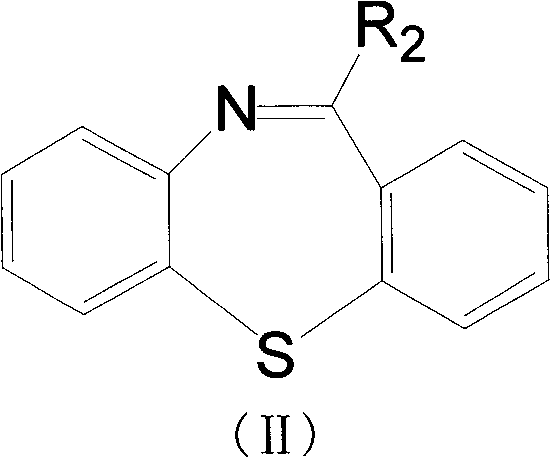

[0020] Take by weighing 30g toluene, iron powder 20mg, auxiliary agent II (R 2 = Cl) 25 mg, and evenly and slowly pass chlorine gas for 4 hours while stirring in the dark, and the temperature in the whole process is controlled at 20°C. After the reaction is completed, filter, wash with water, dry with anhydrous sodium sulfate, and filter. Sampling was carried out for gas chromatography detection, and the toluene conversion rate was 96.5%, the content ratio of p-chlorotoluene and o-chlorotoluene was about 1.8, the content of m-chlorotoluene was 0.10%, and the content of total dichlorotoluene was 0.72%.

Embodiment 3

[0022] Take by weighing 30g toluene, iron powder 20mg, auxiliary agent II (R 2 =NH 2 ) 25 mg, and stirred slowly in the dark for 4 hours, and the temperature of the whole process was controlled at 30 ° C. After the reaction was completed, filtered, washed with water, dried with anhydrous sodium sulfate, and filtered. Sampling was carried out for gas chromatography detection, and the toluene conversion rate was 98.0%, the content ratio of p-chlorotoluene and o-chlorotoluene was about 1.7, the content of m-chlorotoluene was 0.15%, and the content of total dichlorobenzene was 0.84%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com