Trace heating band cutting machine

A technology of heating cable and slitting machine, applied in the field of slitting machine, can solve the problems of difficult welding, low production efficiency, unsuitable for mass production, etc., and achieve the effects of high speed, high precision, and improved production efficiency and yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

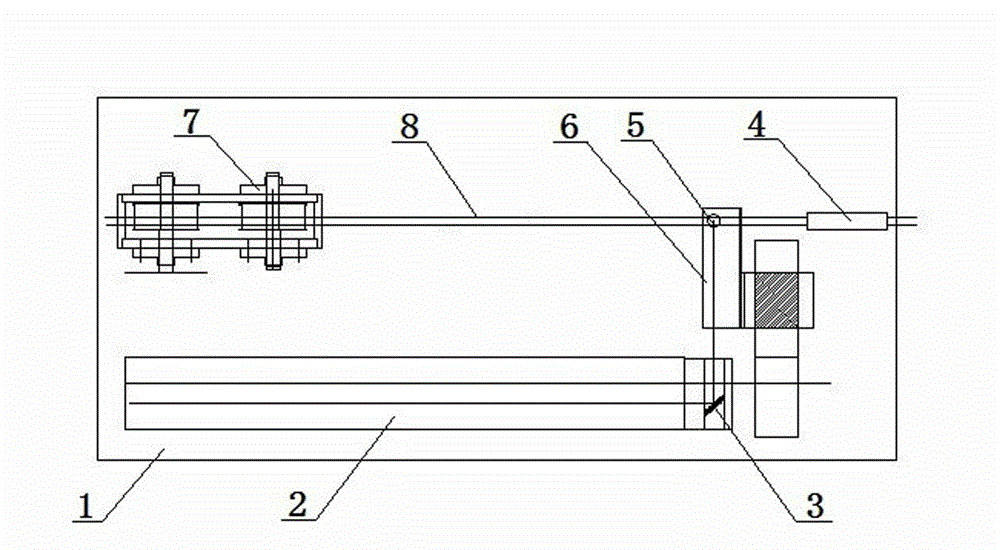

[0012] Such as figure 1 As shown, the heating cable cutting machine of the present invention includes a frame 1 with a laser generator 2 above the frame 1 . The front end of the light outlet of the laser generator 2 has a focusing mechanism 6, and the focusing mechanism 6 has a heating cable delivery port, and a focusing lens 5 is located on the side wall of the heating cable delivery port corresponding to the light outlet of the laser generator 2. In this embodiment, the number of laser generators 2 is two, and the two laser generators 2 are arranged up and down, and the axes of the light outlets are parallel to each other; there are two focusing lenses 5 on the side wall of the heating belt delivery port , the two focusing lenses 5 respectively correspond to the positions of the light exits of the two laser generators 2 . There is a traction mechanism 7 on one side of the focus mechanism 6 above the frame 1, and the axis of the discharge port of the traction mechanism 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com