Preparation method of silicotungstic heteropoly acid loaded catalyst

A supported catalyst and silicotungstic heteropolyacid technology, which is applied in the preparation of organic compounds, the preparation of carboxylate, chemical instruments and methods, etc. Enlargement, good thermal stability, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

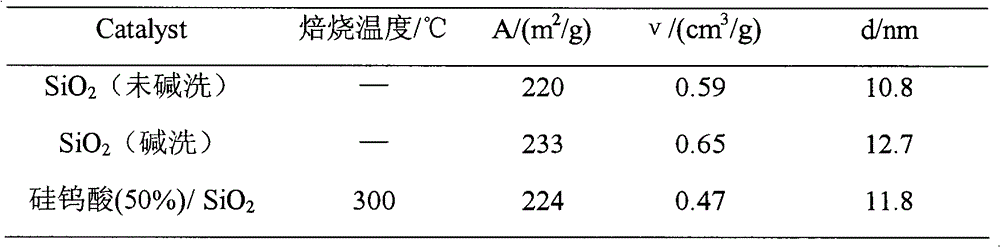

Embodiment 1

[0016] Formed SiO 2 Immersed in 0.01 mol / L Na 2 CO 3 In the solution, the impregnation temperature is 40°C, the impregnation time is 16 hours, and then the impregnated SiO 2 Filter, wash with water until neutral, and dry for later use. Take Keggm structure silicotungstic acid H 3 SiW 12 o 40 · x H 2 Dissolve 20 grams of O(x=0-30) in 10 milliliters of deionized water. Get the SiO that the above-mentioned alkali handles standby 2 20 grams mixed with the above silicotungstic acid solution, deionized water and SiO 2 The liquid-solid ratio is 0.5 ml / g. In a rotary evaporator, the immersion temperature is 60°C, and the immersion is continuously rotated and immersed for 24 hours; then it is taken out and dried under a nitrogen flow for 6 hours at a drying temperature of 120°C; and then under a nitrogen flow, at 300°C 50 wt% silicotungstic acid / SiO was prepared by firing for 3 hours 2 catalyst. Table 1 shows the surface pore parameters of the prepared silicotungstic heterop...

Embodiment 2

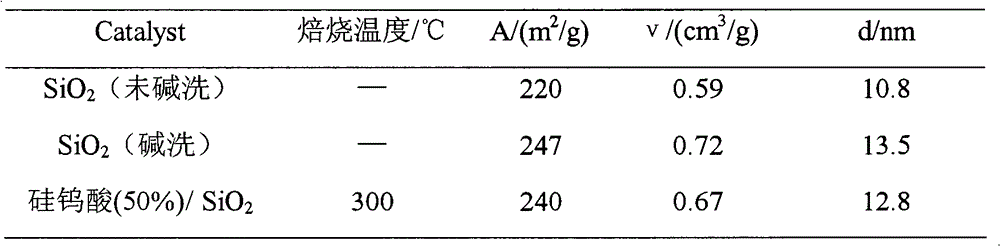

[0021] Formed SiO 2 Immersed in 0.05 mol / L NaHCO 3 In the solution, the impregnation temperature is 30°C, the impregnation time is 18 hours, and then the impregnated SiO 2 Filter, wash with water until neutral, and dry for later use. Take the Keggin structure silicotungstic acid H 3 SiW 12 o 40 · x H 2 O (x = 0 ~ 30) 20 grams is dissolved in 40 milliliters of methanol, take the SiO 2 40 grams are mixed with the above silicotungstic acid solution, methanol and SiO 2 The liquid-solid ratio is 1.0 ml / g. In a rotary evaporator, the immersion temperature is 30°C, and the immersion is continuously rotated and immersed for 18 hours; then it is taken out and dried under nitrogen flow for 3 hours at a drying temperature of 140°C; and then under nitrogen flow, 350°C 44 wt% silicotungstic acid / SiO was prepared by firing for 4 hours 2 catalyst. Table 2 shows the surface pore parameters of the prepared silicotungstic heteropolyacid-supported catalyst.

[0022] Table 2

[0023] ...

Embodiment 3

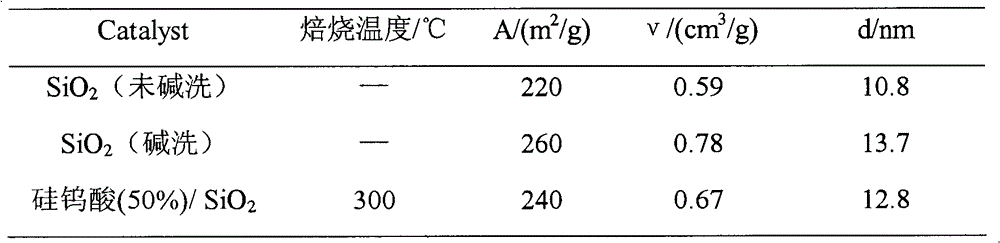

[0026] Formed SiO 2 Immerse in 0.1 mol / L NaOH solution, the impregnation temperature is 50°C, and the impregnation time is 20 hours, and then the impregnated SiO 2 Filter, wash with water until neutral, and dry for later use. Take the Keggin structure silicotungstic acid H 3 SiW 12 o 40 · x H 2 O (x = 0 ~ 30) 30 grams is dissolved in 135 milliliters of ethanol, take the SiO 2 90g is mixed with the above silicotungstic acid solution, ethanol and SiO 2 The liquid-solid ratio is 1.5 ml / g. In a rotary evaporator, the immersion temperature is 40°C, and the immersion is continuously rotated and immersed for 20 hours; then it is taken out and dried under nitrogen flow for 9 hours at a drying temperature of 160°C; and then under nitrogen flow, 400°C 37.5% by weight silicotungstic acid / SiO was prepared by firing for 5 hours 2 catalyst. Table 3 shows the surface pore parameters of the prepared silicotungstic heteropolyacid-supported catalyst.

[0027] table 3

[0028]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com