A kind of pellet forming equipment

A granule forming and equipment technology, applied in the direction of granulation in static tanks/slots, can solve the problems of difficulty in improving the quality of sodium metasilicate and reducing energy consumption, and achieves strong production continuity, improved quality, and low resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

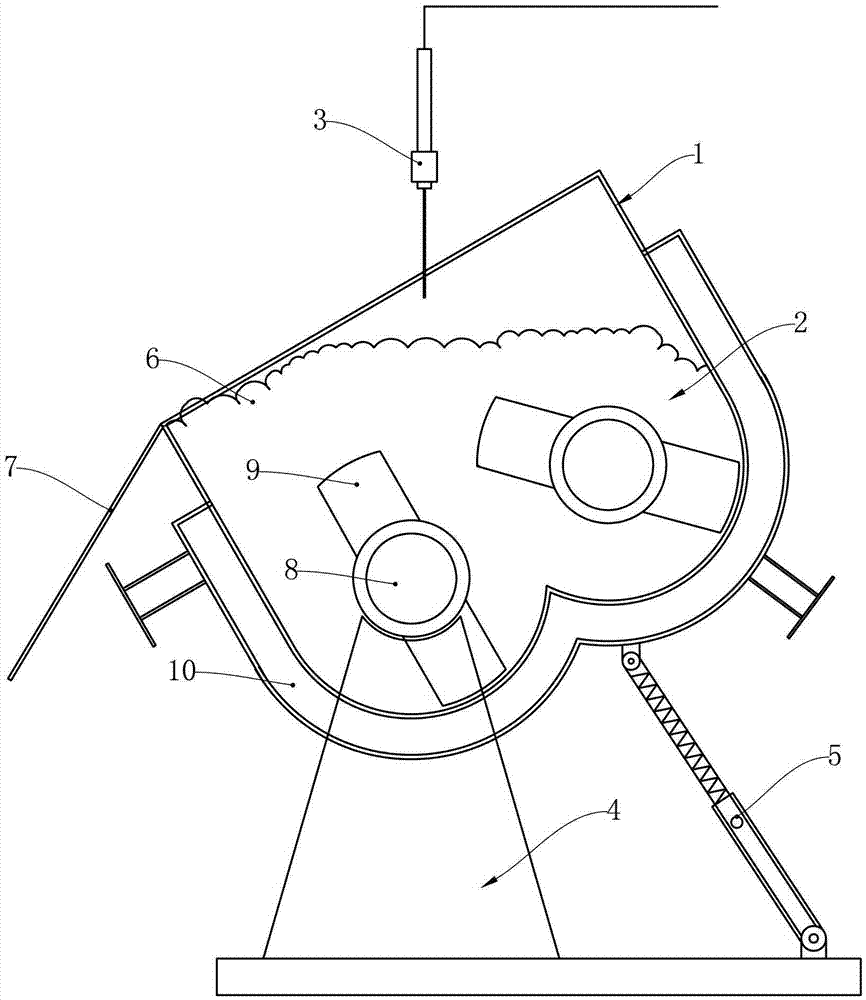

[0039] In this embodiment, the inclination angle of the trough 1 is 25 degrees, and the rotation speed ratio of the stirring shaft 8 on the side far away from the discharge edge of the trough 1 and the stirring shaft 8 on the other side is 1:1.3, which is far away from the discharge edge of the trough 1. The stirring shaft 8 rotating speed on one side is 40 rpm.

Embodiment 2

[0041] In this embodiment, the inclination angle of the trough 1 is 35 degrees, and the rotation speed ratio of the stirring shaft 8 on the side far away from the discharge edge of the trough 1 and the stirring shaft 8 on the other side is 1:2.1, which is far away from the discharge edge of the trough 1. The stirring shaft 8 rotating speed on one side is 20 rev / mins.

Embodiment 3

[0043] In this embodiment, the inclination angle of the trough 1 is 30 degrees, and the rotation speed ratio of the stirring shaft 8 on the side far away from the discharge edge of the trough 1 and the stirring shaft 8 on the other side is 1:1.7, which is far away from the discharge edge of the trough 1. The stirring shaft 8 rotating speed on one side is 30 rev / mins.

[0044] The following table provides a comparison table of the production rate of the equipment and the drum granulator and the disc granulator for the above-mentioned embodiments.

[0045]

[0046] As can be seen from the above table, under the condition that the power of each equipment is consistent, the production rate of each embodiment of the present invention is obviously higher than the traditional drum granulator and disc granulator; Greatly reduce energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com