Geometrical parameter calibration method of X-ray cone beam computed tomography system

A technology of geometric parameters and tomography, used in echo tomography, material analysis using radiation, computer tomography scanners, etc., can solve problems such as complex calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0130] Technical solutions:

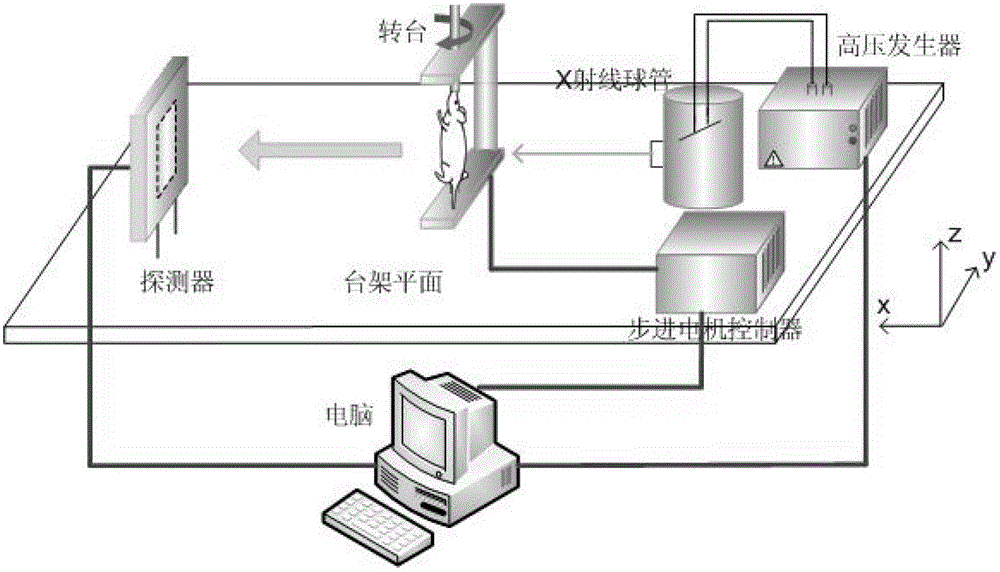

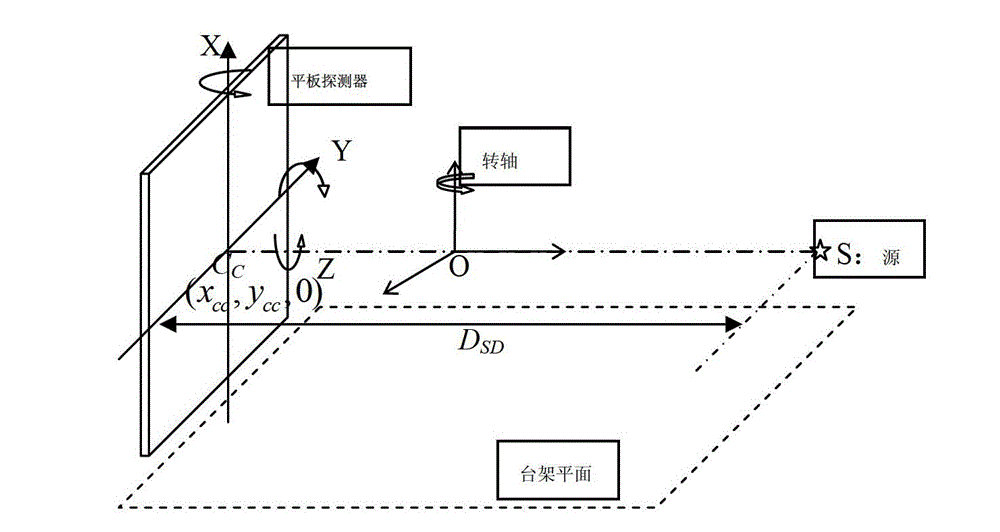

[0131] 1) Establishment of cone beam CT system model

[0132] A typical cone beam CT system includes three parts: X-ray source, flat panel detector and rotation system. During CT reconstruction, the geometric relationship between the three parts is used to reconstruct the density of the detected object or the spatial distribution of the X-ray attenuation coefficient according to multiple projection data. The traditional calibration method is to consider the geometric parameters and errors of the system one by one, and measure and adjust them one by one to make the installation error close to zero and obtain accurate imaging geometric parameters. like figure 1 As shown, the coordinate system of the system is defined with the platform plane of the system as the reference system. The ideal geometric condition is: the line connecting the X-ray source and the center of the flat panel detector passes through the coordinate origin and falls on the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com