Palm olein composition

A technology of palm olein and composition, applied in the fields of inhibiting the fat crystallization, crystallization inhibitor, and palm oil essential oil composition, to achieve the effect of inhibiting triglyceride crystallization and improving the inhibition characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0083] Sodium stearate and sorbitan tristearate (STS) were tested in double-fractionated palm olein as an anti-crystallization agent to delay / reduce the partial crystallization of olein during storage. Sodium stearate in different amounts (such as 0.002%, 0.005%, 0.01%, 0.02%, 0.03% and 0.04%) and STS in different amounts (such as 0.02%, 0.04%, 0.06%, 0.08%, 0.10% and 0.12 %) dosage added to palm olein. After heat-treating the sample at 90°C, place it at a constant temperature as described below, and periodically check crystal formation. The samples were monitored for 205 days.

[0084] The following palm olein samples were tested at the following temperatures:

[0085] ●Palm olein with a cloud point of 5°C (CP 5°C) at a temperature of 20°C

[0086] ●Palm olein with a cloud point of 5°C at a temperature of 18°C

[0087] ●Palm olein with a cloud point of 5℃ at a temperature of 15℃

[0088] ●Palm olein with a cloud point of 10°C (CP 10°C) at a temperature of 20°C

[0089] ●Palm olein w...

example 11-

[0098] Example 1.1-Palm olein at 20°C (CP 5°C)

[0099]

[0100] Table 1

[0101] Degree=The degree of crystallinity after storage at 20°C for 205 days is good, and 10 is bad.

[0102] Sample number = sample number.

[0103] For most samples, it is very difficult to determine the onset time of crystallization due to the combined effect of STS and sodium stearate. The rate of initial crystallization is very slow, so its onset time cannot be determined. For the control sample and the sample with only STS, the onset time of crystallization is more clear. Instead, list the degree of crystallinity after storage days at the desired constant temperature.

[0104] Please note the significant effect caused by only adding 0.01% sodium stearate (Sample 2). The STS score for the 0.12% dose is 3, which is an acceptable result of pure STS and the best result with only STS added. However, the onset of crystallization was detectable after 110 days.

[0105] Adding sodium stearate on top of STS can...

example 12-18

[0107] Example 1.2 Palm olein at-18℃ (CP 5℃)

[0108]

[0109] Table 2

[0110] Onset = start time of crystallization-day

[0111] Sample number = sample number.

[0112] It can be clearly seen from Table 2 that the increasing effect of the combination of sodium stearate and STS. Sodium stearate can keep olein free of visible crystals for 29 days while STS can keep olein free of visible crystals for 21 days. Combining sodium stearate and STS at 0.01% and 0.06% concentrations respectively can delay the onset of crystallization to 277 days.

[0113] Example 1.3 Palm olein at -15℃ (CP 5℃)

[0114]

STS

0%

0.02%

0.04%

0.06%

0.08%

0%

Start

7

10

12

17

8

0.002%

Start

12

14

38

38

38

0.005%

Start

17

20

49

56

38

0.01%

Start

14

49

49

49

49

[0115] table 3

[0116] Onset = start time of crystallization-day

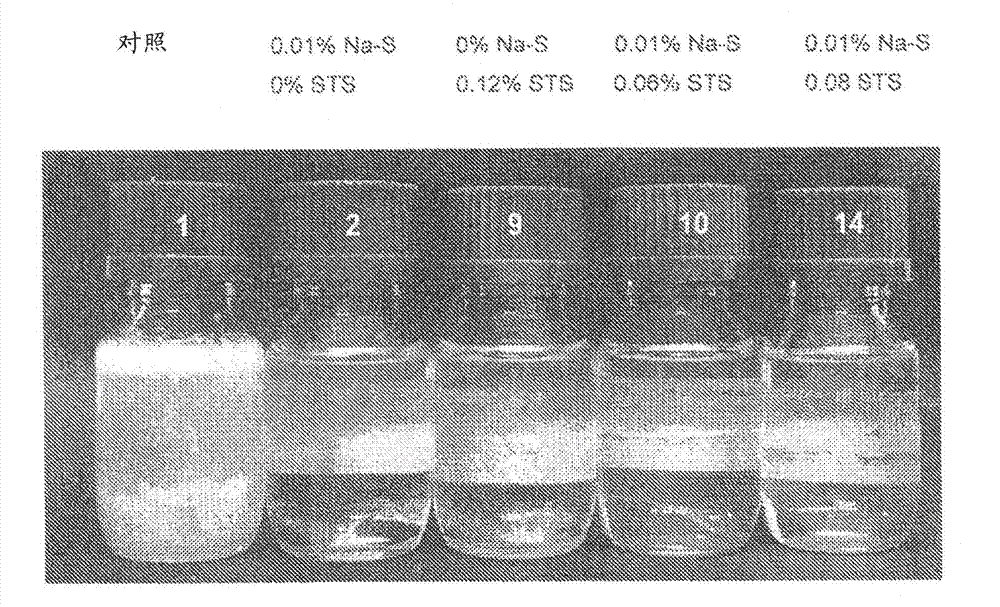

[0117] Many compositions after 47 days of storage image 3 Shown in.

[0118] Sodium stearate delays the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com