Drive device for single-phase series commutator motor

A driving device and motor technology, applied in the direction of electric generator/starter, AC motor control, electric motor/converter plug, etc., can solve the problems of resistor heating, large-scale electric tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

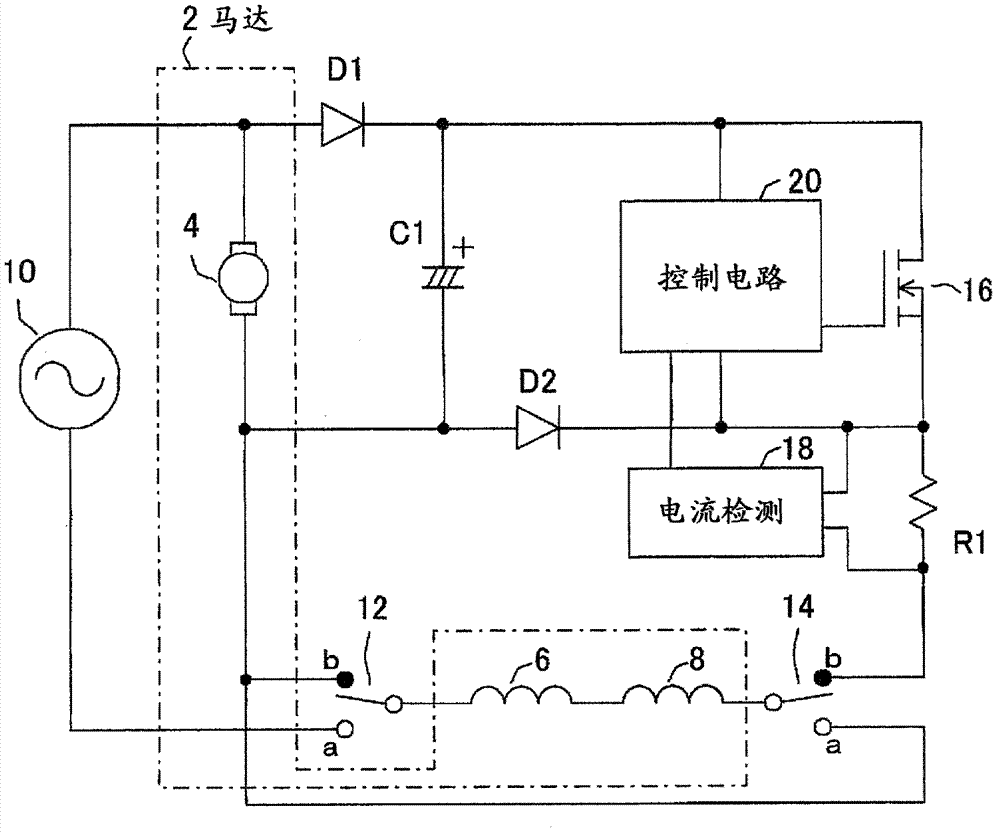

[0051] Hereinafter, the embodiments of the present invention and the appended Figure 1 Same as explanation.

[0052] As shown in FIG. 1, the driving device of this embodiment is a device for receiving power supply from an external AC power source 10 to drive a motor 2 composed of a single-phase series commutator motor. A pair of drive switches 12 and 14 are respectively provided on opposite sides of connection points of field windings (so-called field coils) 6 and 8 (in other words, both ends of field windings 6 and 8 ).

[0053] The motor 2 of this embodiment is used as a power source of an electric tool (such as an electric screwdriver, etc.), and the above-mentioned drive switches 12, 14 are linked with the operation switch of the electric tool. figure 1 On the side of contact b indicated by a black dot, if the operation switch is operated, it switches to figure 1 Side a of the contact point indicated by the white dot.

[0054] Furthermore, when the drive switches 12 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com