Aligning method of mask and workpiece

A mask and workpiece technology, applied in the field of mask and workpiece alignment, can solve problems such as difficult screen mask ScM, workpiece expansion and contraction not necessarily fixed, printing solder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] Embodiments of the present invention will be described below. In the following embodiments, the case where the workpiece shrinks and the pattern shrinks is taken as an example for description. However, it is also applicable to the case where the pattern is enlarged due to the spread of the workpiece.

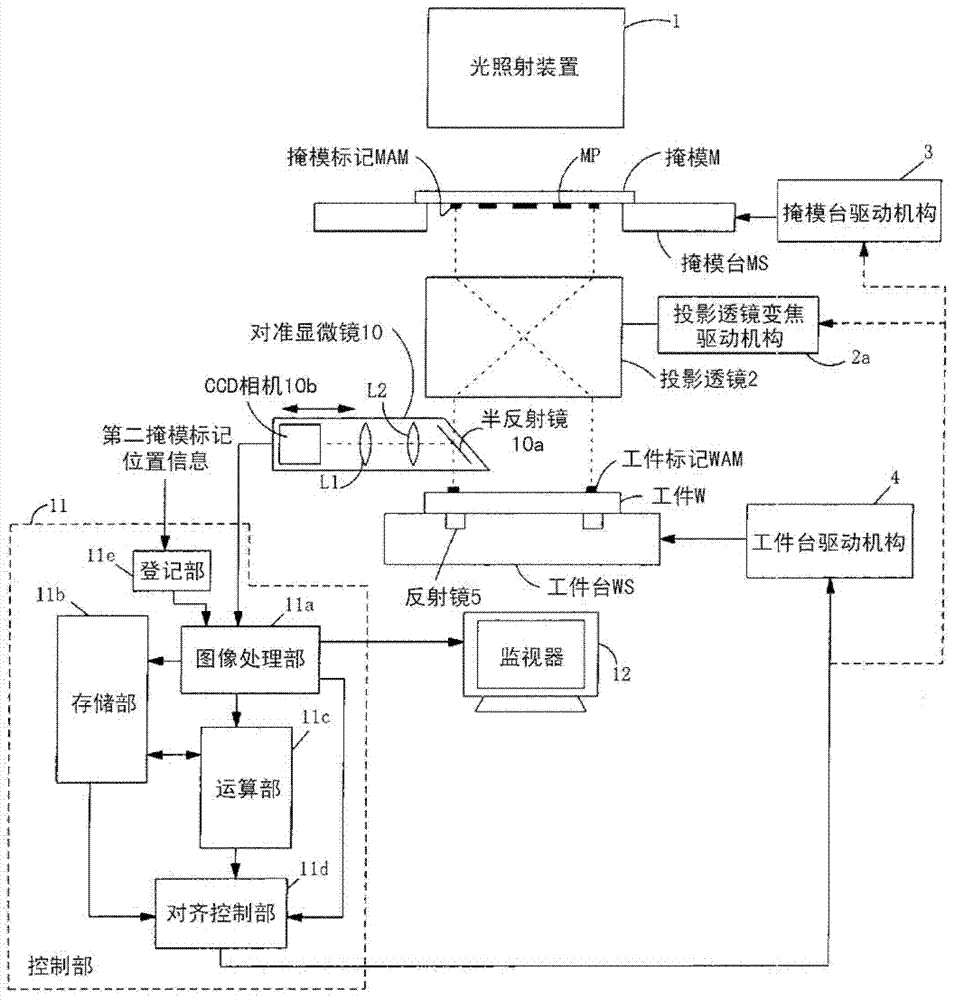

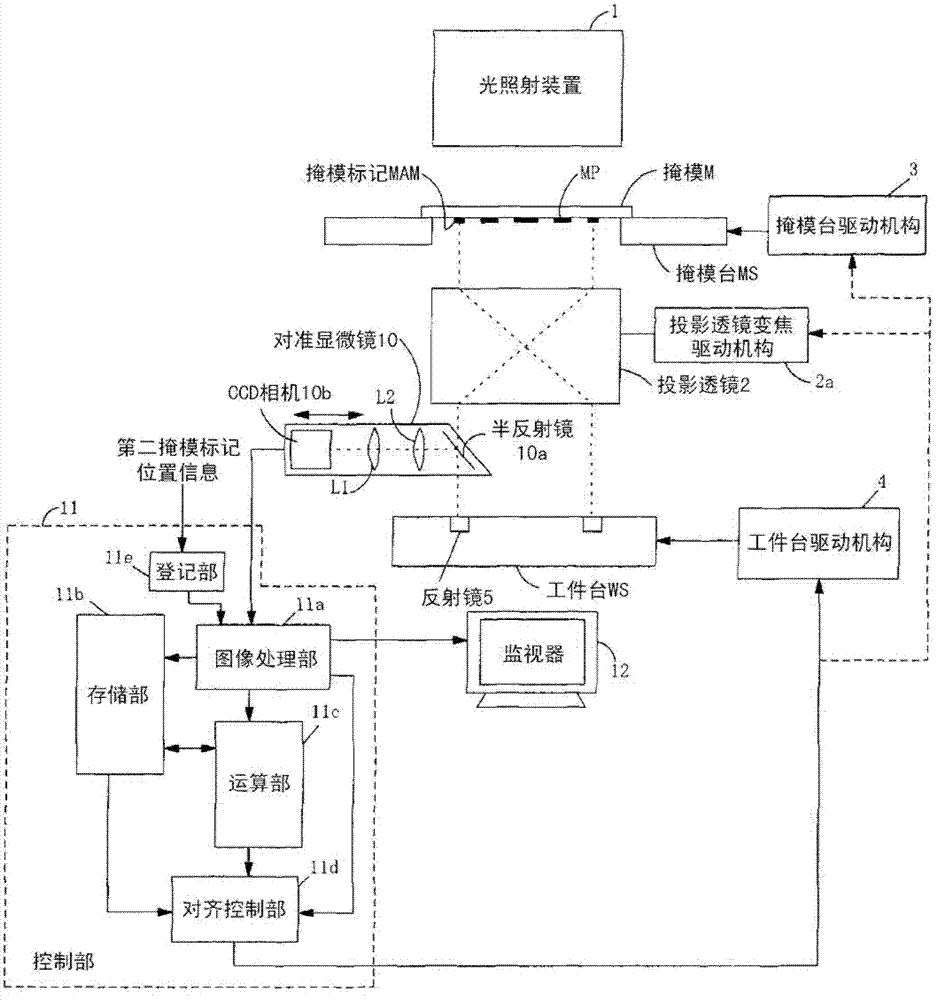

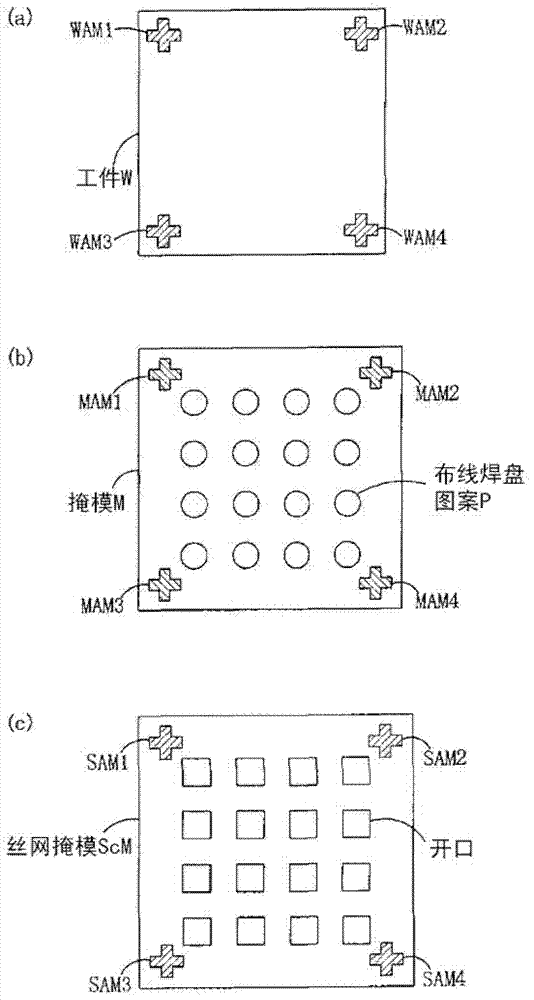

[0094] figure 1 , figure 2 It is a figure which shows the structure of the projection exposure apparatus concerning this invention. In addition, in the present embodiment, the exposure device exposes the entire workpiece (substrate) at one time, and four workpiece marks are formed, and accordingly, four mask marks are also formed.

[0095] In addition, in the following examples, the entire workpiece is exposed collectively, but it can also be applied to exposure in which the workpiece is divided into a plurality of exposure regions and the regions are sequentially exposed.

[0096] exist figure 1 , figure 2 where MS is the mask stage. A mask M formed with a mask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com