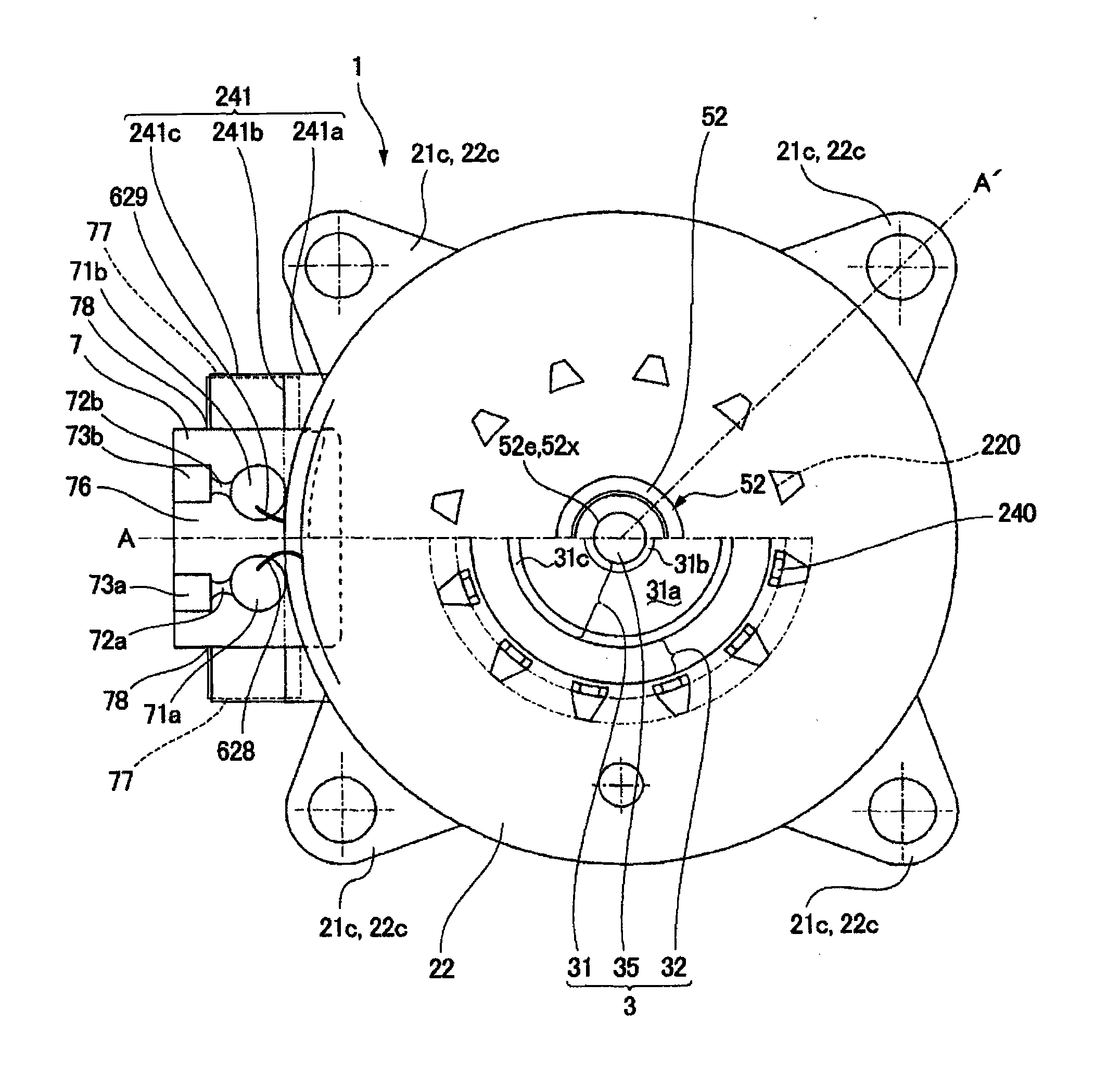

Motor

A technology of electric motors and pole teeth, which is applied in the field of stator structure, can solve the problems of torque drop, complex structure, disconnection, etc., and achieve the effect of reducing the number of parts, realizing thinning and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

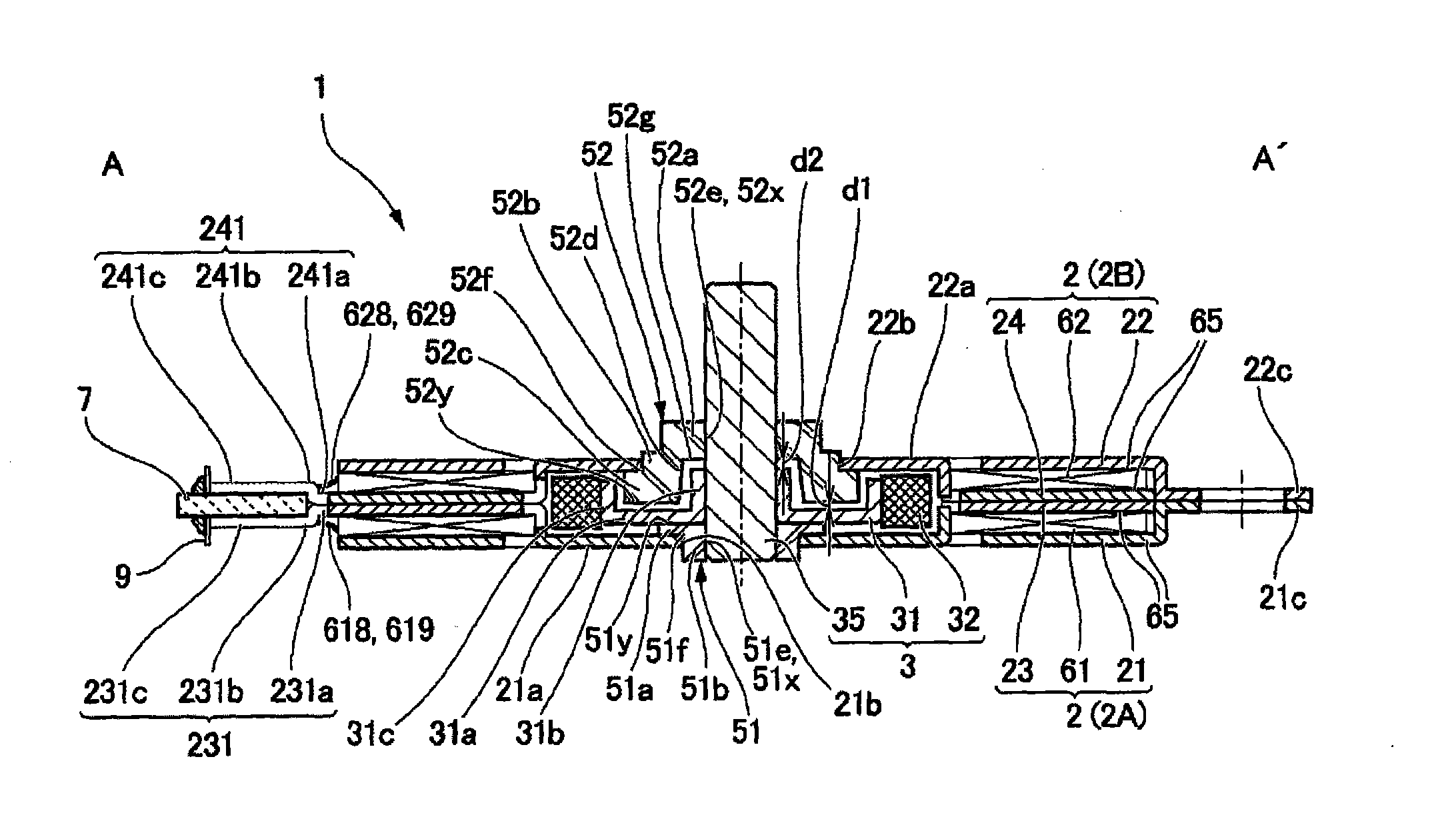

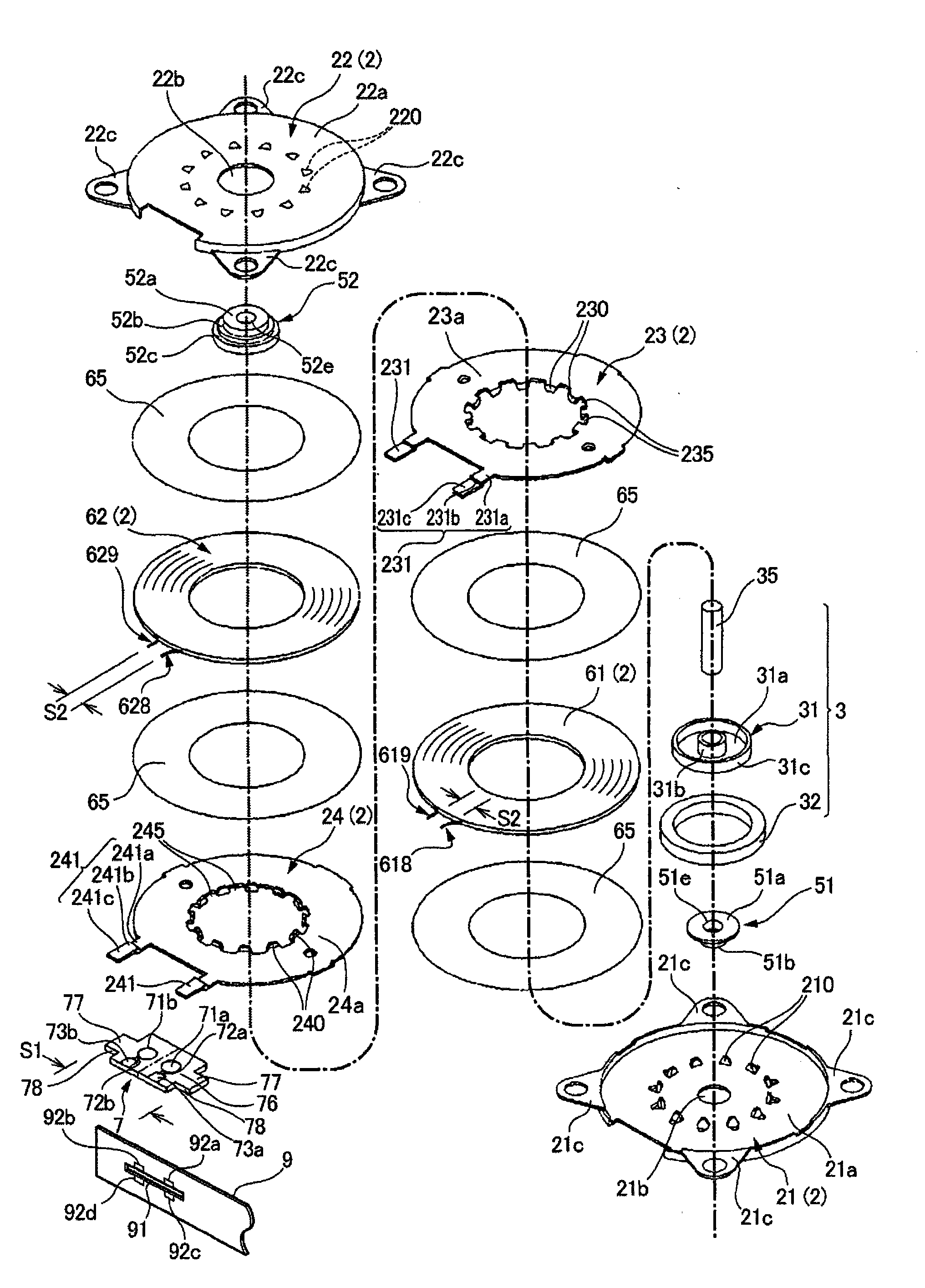

[0153] In the above embodiment, the radial support part and the thrust support part are provided on the anti-output side bearing 51 as the first bearing, and the radial support part and the stop part are provided on the output side bearing 52 as the second bearing. Two bearings, but it is also possible to set a radial support part and a limit part on the anti-output side bearing and use it as the second bearing, and set a radial support part and a thrust support part on the output side bearing and use it as the first bearing . In addition, a structure in which both the anti-output side bearing and the output side bearing are provided with radial support portions and thrust support portions may also be adopted.

[0154] In addition, in the above-mentioned embodiment, a double-sided substrate was used as the substrate 7 for power supply, but a single-sided substrate may also be used, and the winding ends 618, 619, 628, 629 may be wound on the same surface of the substrate 7 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com