Preparation and application of nano-cuprous oxide based enzyme-free hydrogen peroxide sensor electrode

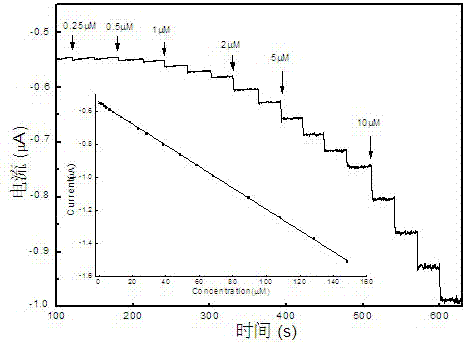

An enzyme-free hydrogen peroxide and nano-cuprous oxide technology, applied in the field of electrochemical analysis and detection, can solve the problems of application limitations, poor stability and regeneration, enzyme inactivation, etc., and achieve short response time, low detection limit, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation process and steps of the cuprous oxide enzyme-free hydrogen peroxide sensor electrode in this embodiment are as follows:

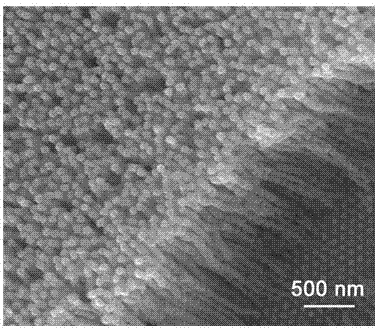

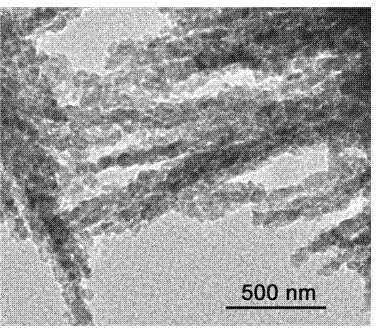

[0021] (1) Preparation of nano cuprous oxide

[0022] Using the porous aluminum oxide film produced by the double anodic oxidation method as a template, a layer of gold film was evaporated on the back as the working electrode, and then the DC electrochemical deposition method was used, with the carbon sheet electrode as the auxiliary electrode, and the electrolyte was 150g / The copper sulfate pentahydrate of L, the lactic acid of 234g / L, adjust the electrolyte pH value to be 11 with the NaOH aqueous solution of 5M. The electrodeposition was carried out in a water bath at 60°C, the deposition voltage was -0.65V, and the deposition time was 40 minutes. After the deposition is completed, the aluminum oxide template is removed in 1M NaOH aqueous solution to obtain cuprous oxide nanowires.

[0023] (2) Preparation of enzyme-free hydroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com