RFID label detection equipment

A technology of RFID tags and testing equipment, which is applied in the field of testing equipment, can solve the problems of low-speed operation, electronic label shutdown and rejection, and the inability to ensure the stability of quality inspection at all times, so as to achieve the effect of providing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

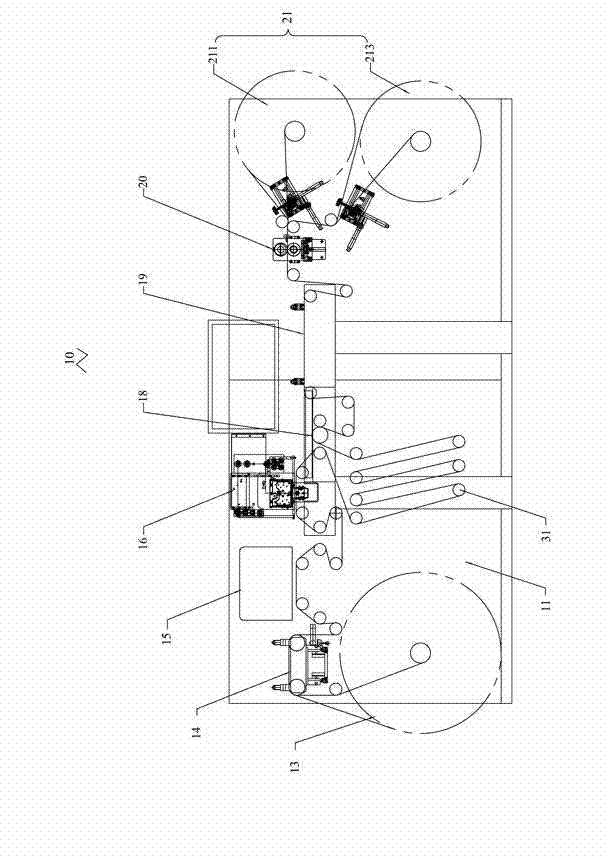

[0012] The present invention will be further described below in conjunction with the description of the drawings and the specific embodiments.

[0013] See figure 1 The present invention provides an RFID tag detection device 10, which includes a frame 11, an unwinding unit 13 and a winding unit 21 respectively arranged at both ends of the frame 11. The unwinding unit 13 and the rewinding unit 21 are further provided with a correction unit 14, a label conduction detection unit 15, a visual detection unit 16, a main traction unit 18, and a label changing platform 19 in sequence. A paper guide roller 31 for conveying printing materials is provided between each unit.

[0014] The unwinding unit 13 includes a rotating unwinding air expansion shaft and a first motor, and the unwinding air expansion shaft is used for placing roll-type printing materials. The working principle of the unwinding air expansion shaft is: a clamping block is arranged on the unwinding air expansion shaft, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com