Dynamic rotary kiln supporting roller shaft deflection variation and cylinder bending measuring method and instrument

A measuring method and technology of supporting roller shaft, applied in the direction of instruments, measuring devices, etc., can solve the problems of easy hidden submersion, large measurement error of deflection change, etc., and achieve the effect of preventing sudden breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below with reference to accompanying drawing and specific embodiment:

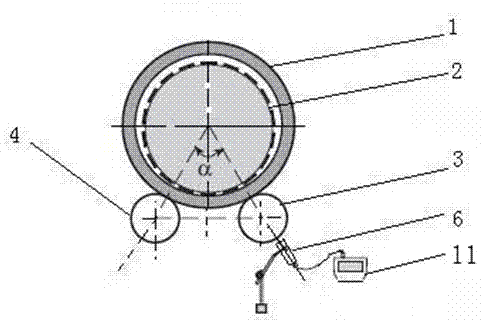

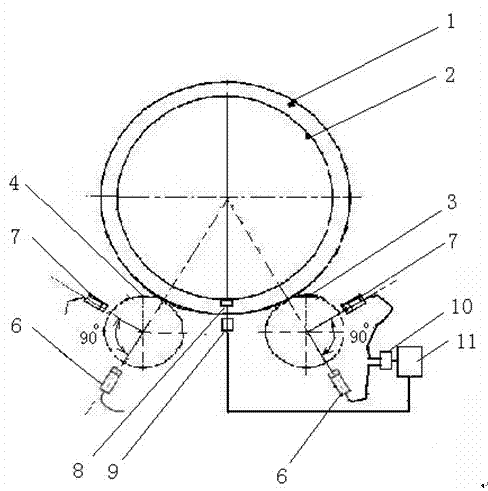

[0021] figure 1 It has been introduced in the existing background technology section, and is omitted here. like figure 2 Shown, the inventive method concrete method is as follows:

[0022] At a fixed position below the high end of the cylinder, use a trigger 8 to adsorb on the cylinder 2 to determine the busbar for starting and ending the measurement, use a position sensor 9 to measure the rotation period of the cylinder 2, and use the equal cycle time to determine Determine the rotation orientation of the barrel.

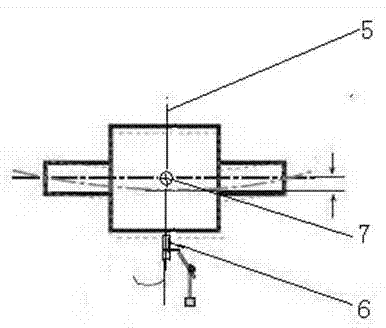

[0023] (1) if image 3 As shown, at the same middle section 5 of the left supporting wheel 4 of the same block, two displacement sensors perpendicular to each other are installed in alignment with the center of the left supporting wheel. The first displacement sensor 6 on the extension line of the connection between the left supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com