Lamp device and luminaire

A technology for lighting devices and installation parts, which is applied to lighting devices, fixed lighting devices, lighting and heating equipment, etc. It can solve problems such as difficult exporting, achieve the effects of reducing losses, improving exporting efficiency, and reducing distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

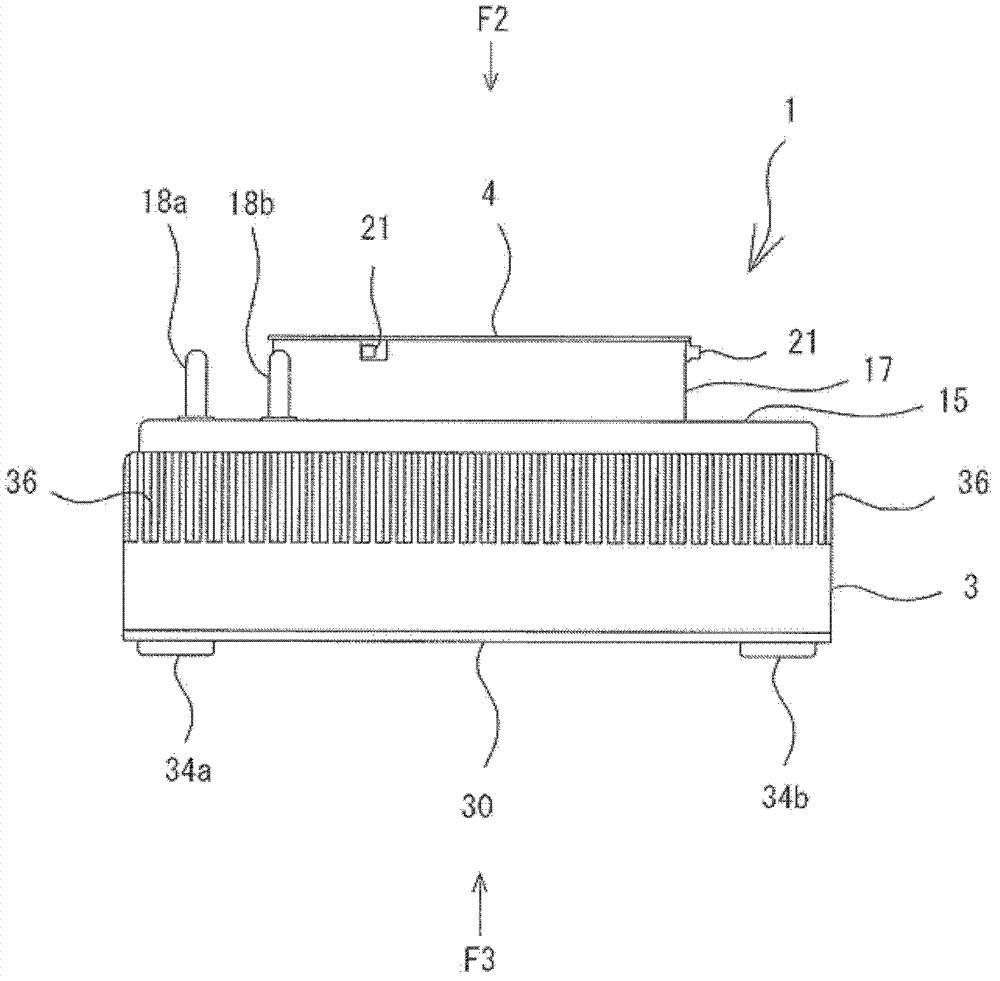

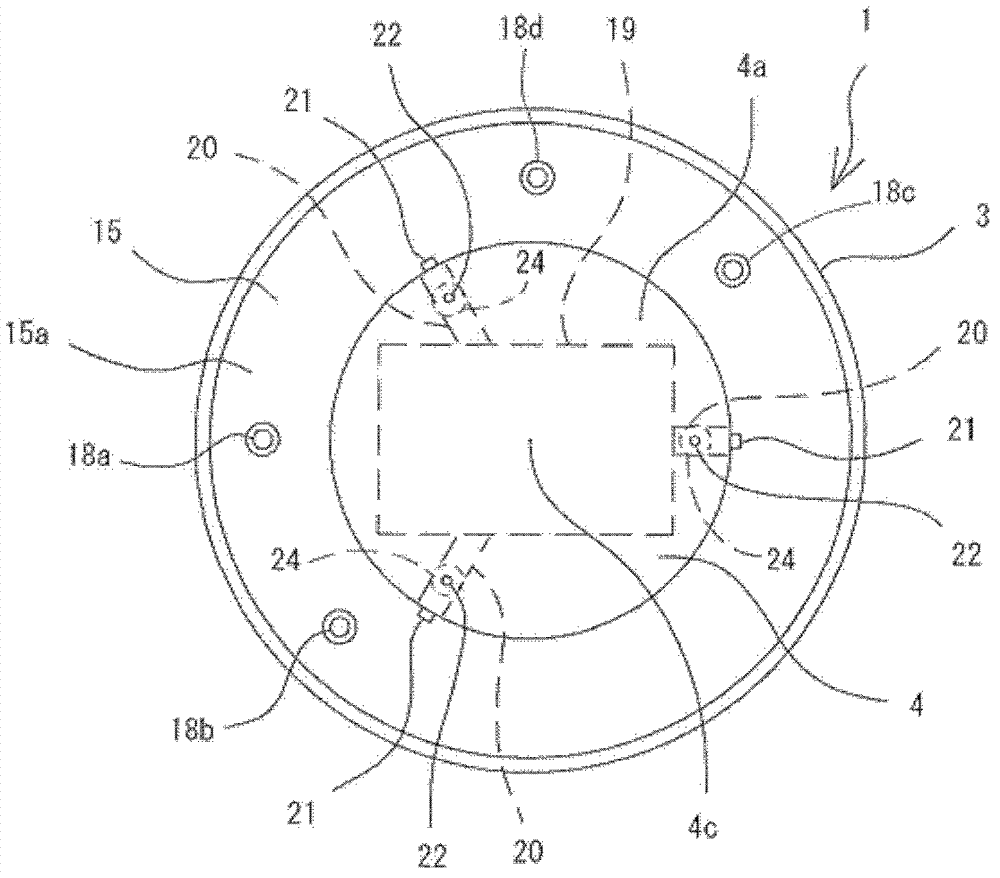

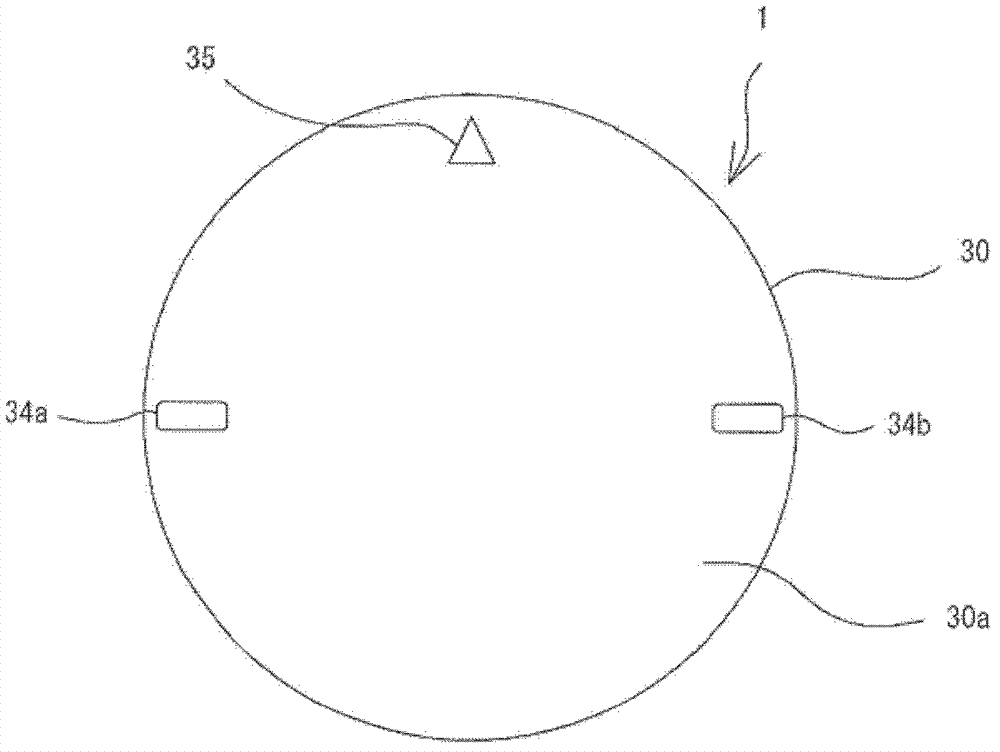

[0133] Below, refer to Figure 1 to Figure 4 The lamp device of the first embodiment will be described.

[0134] figure 1 It shows a thin lamp device 1 having a light distribution suitable for a downlight or a spotlight, for example. The lamp device 1 includes a light emitting module 2 , a main body 3 , a heat dissipation member 4 , a support member 5 , and a lighting device 6 .

[0135] The light emitting module 2 has a module substrate 7 , a plurality of light emitting diodes 8 and a sealing material 9 . The module substrate 7 is made of a metal material excellent in heat dissipation, such as aluminum. The module substrate 7 has a substantially rectangular shape and has a first surface 7 a and a second surface 7 b. The first surface 7a is covered with an insulating layer not shown. The second surface 7b is located on the back side of the first surface 7a.

[0136] The light emitting diode 8 is an example of a luminous body. The light emitting diode 8 is, for example, ...

no. 2 Embodiment approach

[0182] Figure 5 The second embodiment is disclosed. The lamp device 1 of the second embodiment has a reflector 60 housed inside the main body 3 . The configuration of the lamp device 1 other than the reflector 60 is the same as that of the first embodiment. Therefore, in the second embodiment, the same reference numerals are attached to the same components as those in the first embodiment, and description thereof will be omitted.

[0183] like Figure 5 As shown, the reflector 60 is an element for controlling the luminous intensity of the lamp device 1 . The reflection plate 60 includes a support portion 61 and a light reflection portion 62 . The support portion 61 has a cylindrical shape and is supported on the first surface 7 a of the module substrate 7 so as to surround the frame 12 of the light emitting module 2 . The reflective portion 62 has a shape expanding from one end of the support portion 61 toward the edge of the opening 14 of the main body 3 . Therefore, t...

no. 3 Embodiment approach

[0187] Image 6 as well as Figure 7 The third embodiment is disclosed. The third embodiment discloses a lighting fixture 46 using the lamp device 1 disclosed in the first embodiment or the second embodiment as a light source. In the third embodiment, the same reference numerals as those of the lamp device 1 of the first embodiment or the second embodiment are assigned to the lamp device 1 , and description thereof will be omitted.

[0188] Image 6 as well as Figure 7 The illustrated lighting fixture 46 is, for example, a down light embedded in the ceiling of a dwelling. The lighting fixture 46 includes a lamp socket 47 and a fixture main body 48 . The tool body 48 is, for example, a die-cast product made of aluminum. The tool body 48 has a substantially cylindrical shape and has a lower end 48a and an upper end 48b. A lower end 48 a of the tool body 48 defines a circular opening 49 . The inner peripheral surface 48d of the instrument main body 48 is painted in white...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com