Ferroalloy material for producing golf club ball

A technology for golf clubs and alloy materials, applied in golf balls, golf clubs, rackets, etc., can solve the problems of complex production process, difficult cutting processing, poor process performance, etc., and achieve a wide market, low cost, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

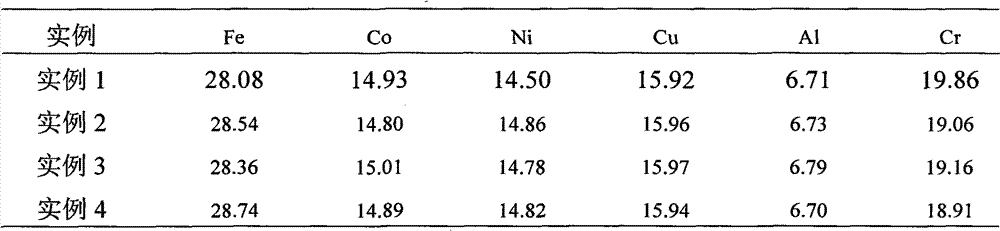

[0010] The main process of alloy material preparation: material preparation of each element → sawing → cleaning and descaling → proportioning → cleaning → electric arc furnace melting → sampling → cooling → sample preparation → heat treatment → analysis of structure and mechanical properties. Its electric arc furnace melting current ranges from 650A to 760A. The samples for heat treatment and mechanical performance experiments are cylinders with a diameter of 5mm×10mm, and the purity of all alloy elements is above 99.9%. The alloy material is based on the molar composition ratio of each element and the molecular formula is Fe 2 CoNiCuAlCr 1.5 Do ingredient ratios. Tables 1 and 2 are the composition ratio and mechanical properties of each example respectively.

[0011] The composition (mass percentage / %) of each example alloy of table 1

[0012]

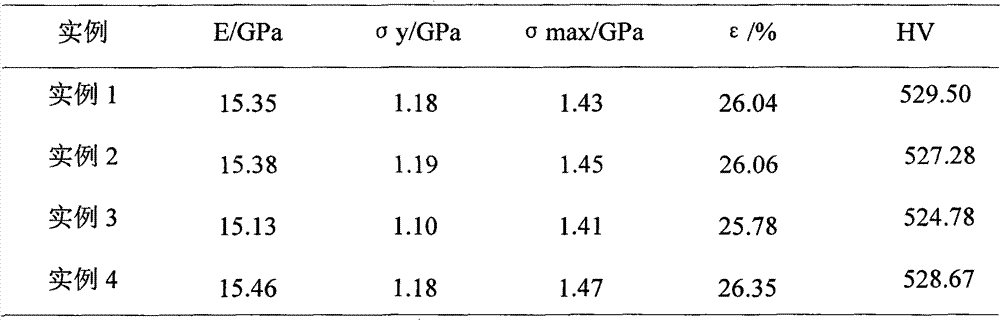

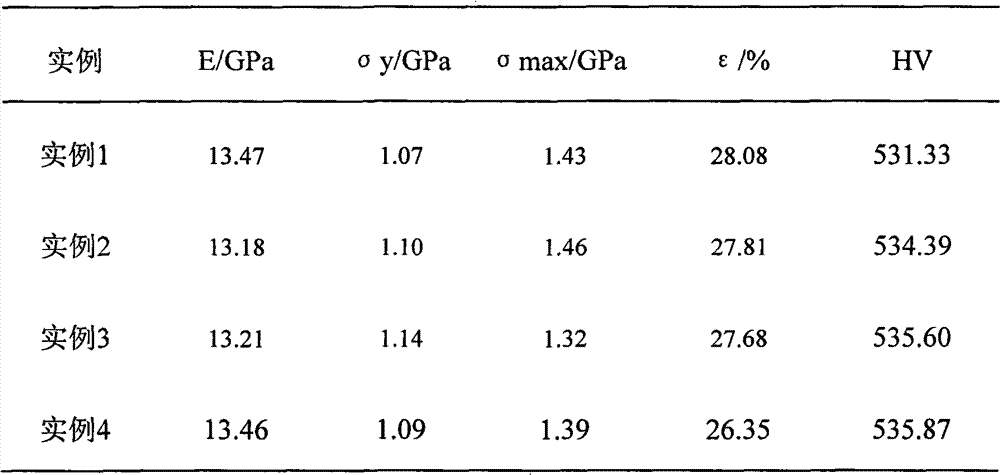

[0013] Table 2 mechanical properties of each example

[0014]

[0015] The heat treatment process of the alloy material a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com