preparation method of spherical ti3al/tial two-phase alloy

A dual-phase alloy, spherical technology, applied in the field of dual-phase alloy preparation, can solve the problems of poor sintering performance, difficult to control the composition of TiAl alloy, high impurity content, etc., achieve good thermal processing performance, reduce energy consumption and preparation costs, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

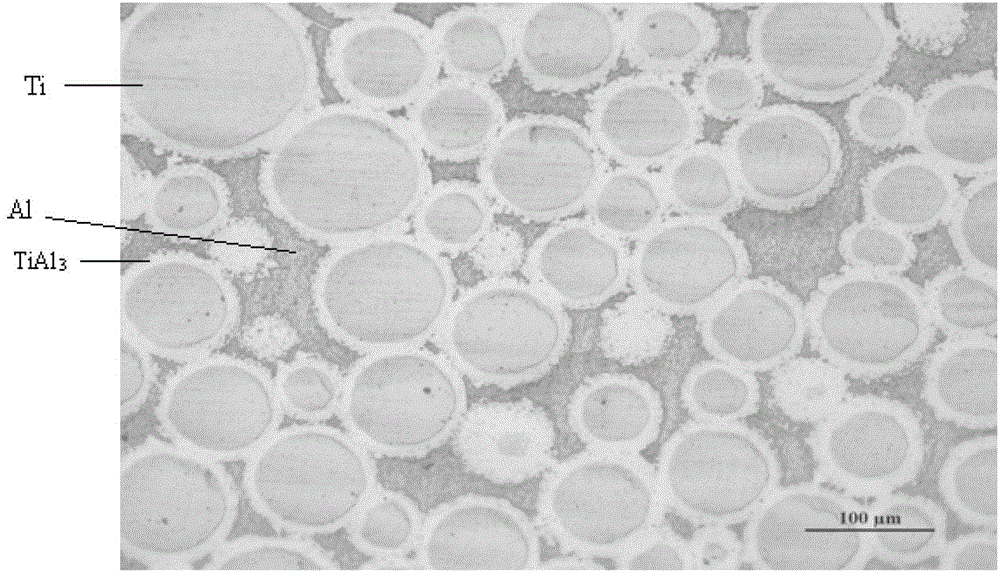

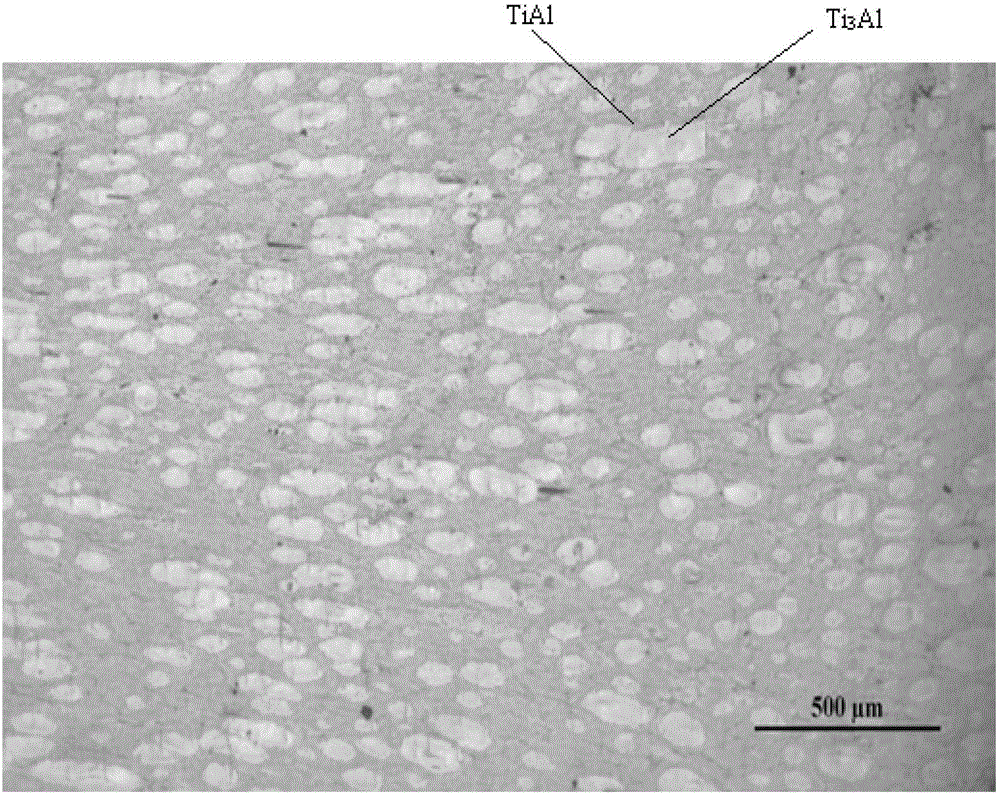

[0019] Specific embodiment one: a kind of spherical Ti of this embodiment 3 The Al / TiAl dual-phase alloy is composed of Ti and Al, wherein the mass ratio of Ti and Al is 65-68:32-35.

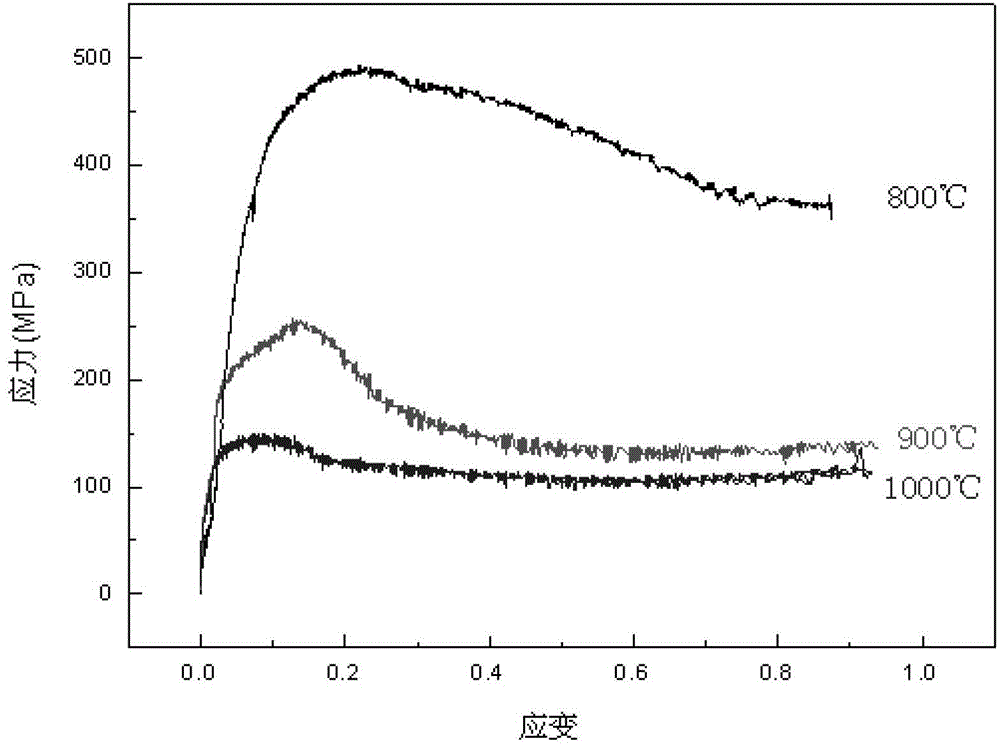

[0020] This embodiment solves the key problem that the TiAl dual-phase alloy is difficult to be hot-formed. In this embodiment, an appropriate amount of spherical Ti with good deformability is distributed in TiAl 3 Al, can significantly change the hot workability of TiAl dual-phase alloys. Whether it is compared with the full lamellar structure or the TiAl dual-phase alloy with the double state structure, the spherical Ti 3 The Al / TiAl dual-phase alloy has the best high-temperature deformation ability, which can avoid the problems of difficult thermal processing, high impurity content, and poor sintering performance of the brittle TiAl dual-phase alloy.

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that: the purity of Ti is 99.0%-99.9%, and the purity of Al is 99.0%-99.9%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: a kind of spherical Ti of this embodiment 3 The preparation method of Al / TiAl dual-phase alloy is carried out according to the following steps: 1. After mixing according to the ratio of Ti and Al mass ratio of 65-68:32-35, put it into a vacuum hot-pressing sintering furnace, at the impregnation temperature Under the condition of 660℃~720℃, impregnate for 0.5~3h to get Ti-Al-TiAl 3 Three-phase complex; Two, the Ti-Al-TiAl that step 2 obtains 3 The three-phase composite is placed in a vacuum hot-pressing sintering furnace, the temperature of the vacuum hot-pressing sintering furnace is raised to 1100 ° C ~ 1400 ° C, pressurized to 40 ~ 80 MPa, kept for 0.5 ~ 2 hours, and then cooled with the furnace to obtain spherical Ti 3 Al / TiAl dual phase alloy.

[0023] The beneficial effects of this embodiment are:

[0024] 1. This embodiment solves the key problem that the TiAl dual-phase alloy is difficult to be hot-formed. In this embodiment, an app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com