Waterborne dispersion resin containing hydroxyl and preparation method thereof

A water-based dispersion and resin technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of insignificant improvement in water resistance and chemical medium resistance of the coating film, failure to meet environmental protection requirements, human body and environmental hazards, etc., to achieve Improve hardness and chemical medium resistance, avoid adverse effects, and increase crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

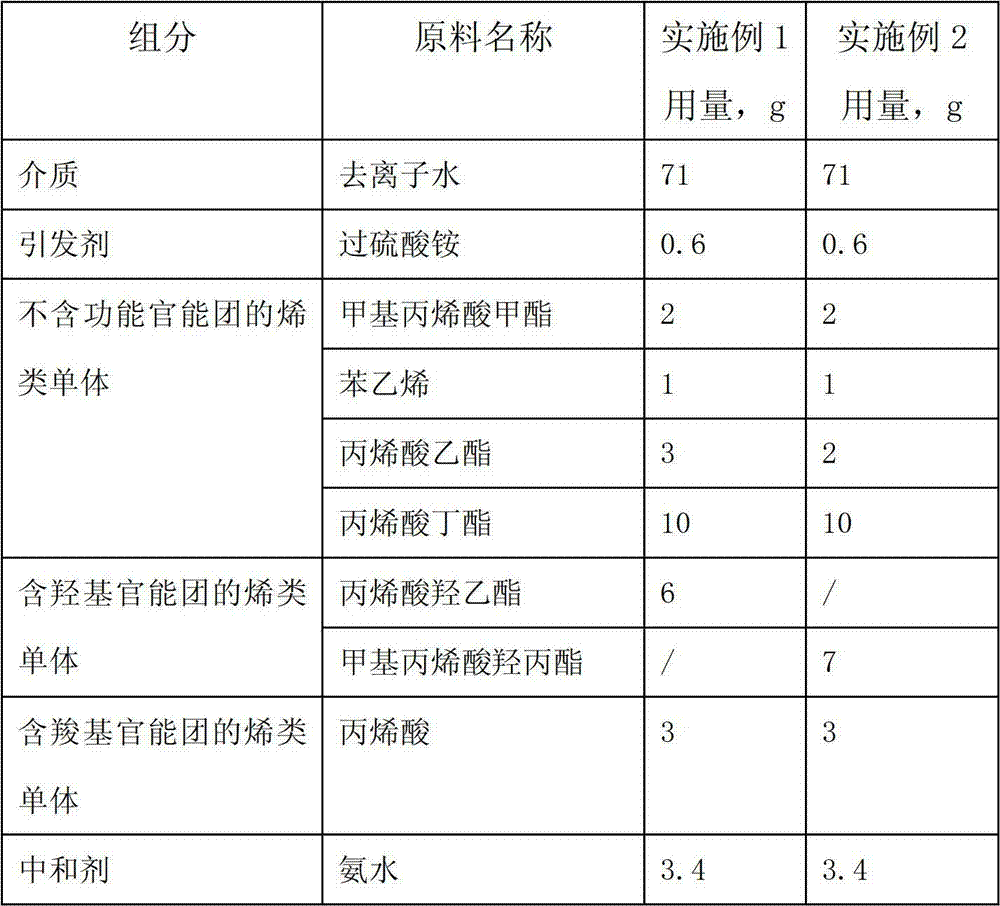

Examples

Embodiment 3

[0026] Implementation 3 prepares waterborne two-component polyurethane coating

[0027] The water-based two-component polyurethane coating consists of two components, A and B. The first component of the coating is the water-dispersible isocyanate Bayhydur XP2655 produced by Bayer in Germany; the second component of the coating is composed of the following components. The components and their dosage are shown in the table 2

[0028] Table 2

[0029]

[0030] Preparation method: Mix water, pigment dispersant, titanium dioxide, and defoamer evenly, grind and disperse with a sand mill until the fineness is ≤25 μm, and prepare the color paste. Add acrylic acid hydroxyl dispersion and bactericide to the color paste prepared above and stir evenly, slowly add thickener under stirring condition, after stirring evenly, use 120 mesh silk screen to filter out impurities to obtain the second component of the coating .

[0031] Before use, mix uniformly according to the mass ratio of ...

Embodiment 4

[0052] The coatings prepared in Example 4 and Comparative Example 2 were directly coated on the samples; the baking conditions of the samples were baked at 140±2)°C for 20 minutes, and then the various properties were tested according to the relevant national paint standards. The results are shown in Table 4;

[0053] Table 4

[0054] Test items

Example 3

Example 4

Comparative example 1

Comparative example 2

Gloss (60°)

83

80

52

70

pencil hardness

4H

3H

3H

2H

Water resistance, 30d

no change

no change

16d slightly discolored

18d slightly discolored

Alkali resistance (10%NaOH), 10d

no change

no change

6d slightly discolored

7d slightly discolored

Acid resistance (10%H2SO4), 48h

No abnormality

No abnormality

24h foaming

24h foaming

Resistant to 120# gasoline, 7d

no change

no change

no change

no change

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com