Method for enhancing strength of microfiber glass wool

A technology of glass wool and microfiber, applied in the direction of glass manufacturing equipment, manufacturing tools, etc., can solve the problems that cannot meet the needs, and achieve the effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

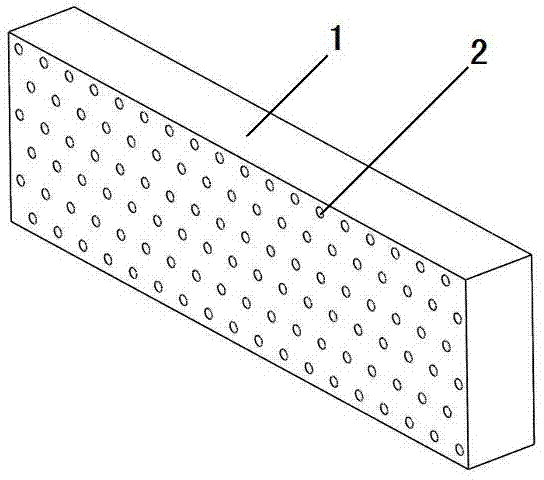

Image

Examples

Embodiment

[0013] The low calorific value gas we use can be yellow phosphorus tail gas (its CO content reaches 87%-92%, and its calorific value is 2500-2900KCa / m 3 ) or coal mine gas (calorific value is 3100-4000KCa / m 3 ).

[0014] Our research direction: the combustible gas is under pressure, and its combustion flame heats the glass filaments. At the same time, the gas pressure blows the glass filaments out forcefully, and the glass filaments are heated and compressed in a short time, thereby expanding into microfiber glass wool. Therefore, the production process of microfiber glass wool is affected by both heating and pressurization, and the tensile strength of the product is affected by pressure. If the injection pressure of the gas can be increased (for natural gas, the flow rate is 0.012m 3 / s), it is bound to be able to increase the tensile strength. But what follows is that due to the increase of gas flow rate, the volume of gas burned per unit time increases, then the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com