Sewage treatment method in synthetic rubber production

A sewage treatment method and synthetic rubber technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of synthetic rubber sewage effluent not meeting discharge standards, high investment cost, Problems such as the complete oxidation treatment of rubber sewage cannot be applied to achieve the effects of pollutant emission reduction, safe and reliable operation, and great practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

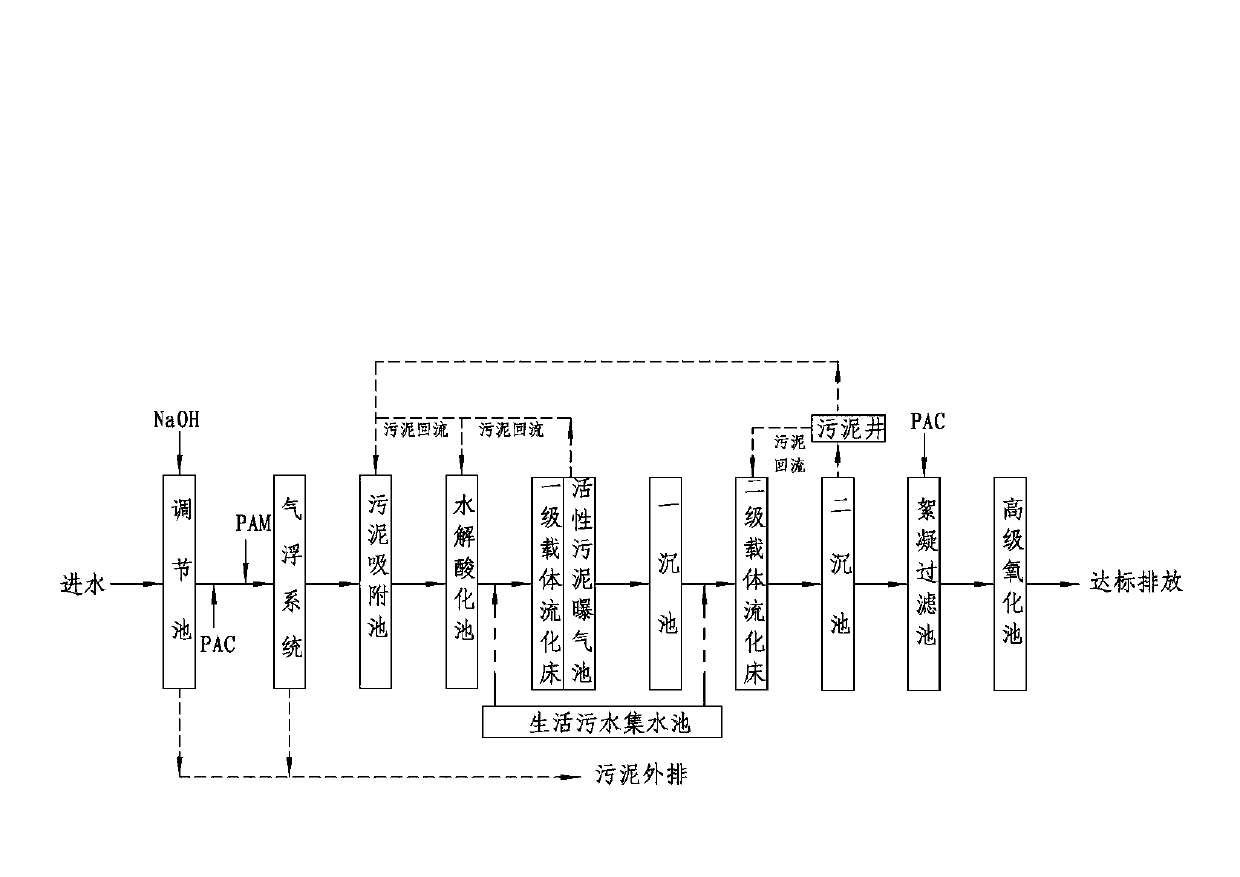

[0029] A synthetic rubber production sewage (COD is 922.3mg / L, flow rate is 150 m 3 / h) enter figure 1 In the process flow shown, the main process parameters of each treatment unit are: the pretreatment unit adds NaOH to adjust the pH value to 8.5, the addition amount of PAC and PMA is 200mg / L and 4mg / L respectively, and the air flotation residence time is 0.5h. The effluent COD of this unit is 719mg / L, and the COD removal rate is 22%.

[0030] Sewage enters the sludge adsorption tank to remove the remaining suspended solids and colloidal particles in the pretreatment unit. After adsorption, the COD drops to 371.3mg / L, and the COD removal reaches 48%.

[0031]The sewage then enters the hydrolytic acidification tank with a hydraulic retention time of 8 hours, dissolved oxygen DO: 0.3 mg / L, and sludge concentration MLSS: 8000 mg / L. The B / C of this unit is increased from 0.3 to 0.5, the effluent COD concentration is 295mg / L, and the COD removal rate is 21%.

[0032] The sewage...

Embodiment 2

[0035] A synthetic rubber production sewage (COD is 1069mg / L, flow rate is 200 m 3 / h) enter figure 1 In the process flow shown, the main process parameters of each treatment unit are: the pretreatment unit adds NaOH to adjust the pH value to 8.9, the addition amount of PAC and PMA is 300mg / L and 5mg / L respectively, and the air flotation residence time is 1h. The effluent COD of this unit is 965mg / L, and the COD removal rate is 21%.

[0036] The sewage enters the sludge adsorption tank to remove the remaining suspended solids and colloidal particles in the pretreatment unit. After adsorption, the COD drops to 495mg / L, and the COD removal reaches 43%.

[0037] The sewage then enters the hydrolysis acidification tank with a hydraulic retention time of 13h, dissolved oxygen DO: 0.2 mg / L, and sludge concentration MLSS: 9000mg / L. The B / C of this unit is increased from 0.4 to 0.6, the effluent COD concentration is 309mg / L, and the COD removal rate is 21%.

[0038] The sewage afte...

Embodiment 3

[0041] A synthetic rubber production sewage (COD is 761.2mg / L, flow rate is 120 m 3 / h) enter figure 1 In the process flow shown, the main process parameters of each treatment unit are: the pretreatment unit adds NaOH to adjust the pH value to 7.5, the addition amount of PAC and PMA is 200mg / L and 3mg / L respectively, and the air flotation residence time is 0.5h. The effluent COD of this unit is 601mg / L, and the COD removal rate is 21%.

[0042] Sewage enters the sludge adsorption tank to remove the remaining suspended solids and colloidal particles in the pretreatment unit. After adsorption, the COD drops to 312mg / L, and the COD removal reaches 48%.

[0043] The sewage then enters the hydrolytic acidification tank with a hydraulic retention time of 10.0h, dissolved oxygen DO0: 0.15 mg / L, and sludge concentration MLSS: 7000mg / L. The B / C of this unit is increased from 0.3 to 0.5, the effluent COD concentration is 234mg / L, and the COD removal rate is 25%.

[0044] The sewage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com