System and method for purifying polysilicon through continuous slagging under electric field

A polysilicon and slag-making technology, which is applied in the field of high-purity polysilicon preparation system, can solve the problems of reduced purification effect, low production efficiency, energy waste, etc., to shorten the heating time of the cold furnace, high production efficiency, and reduce slagging agents The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

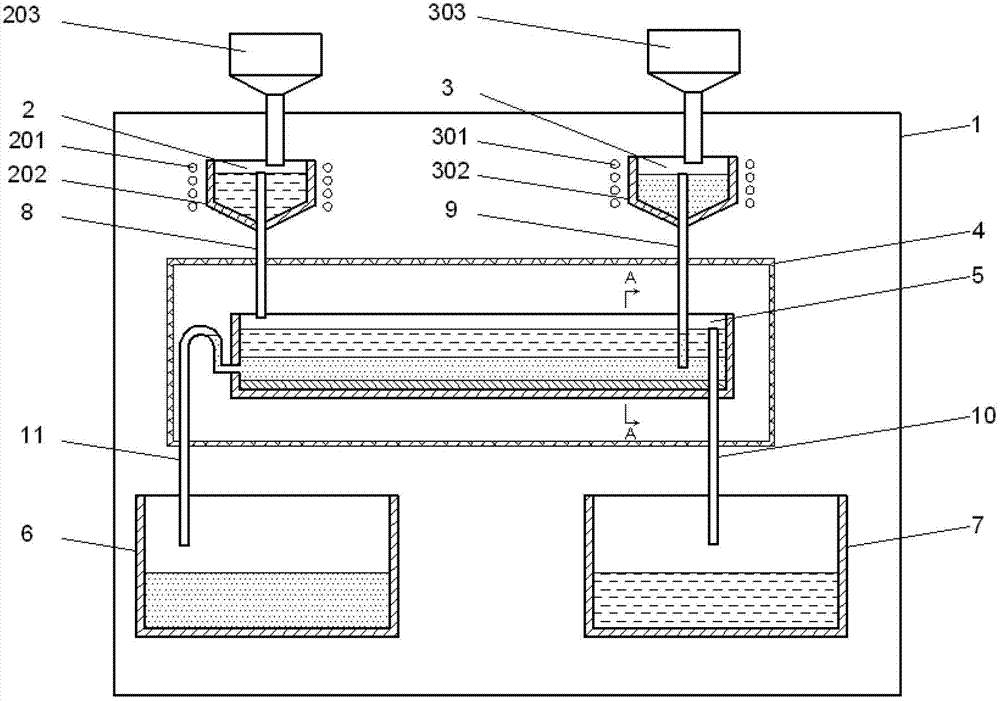

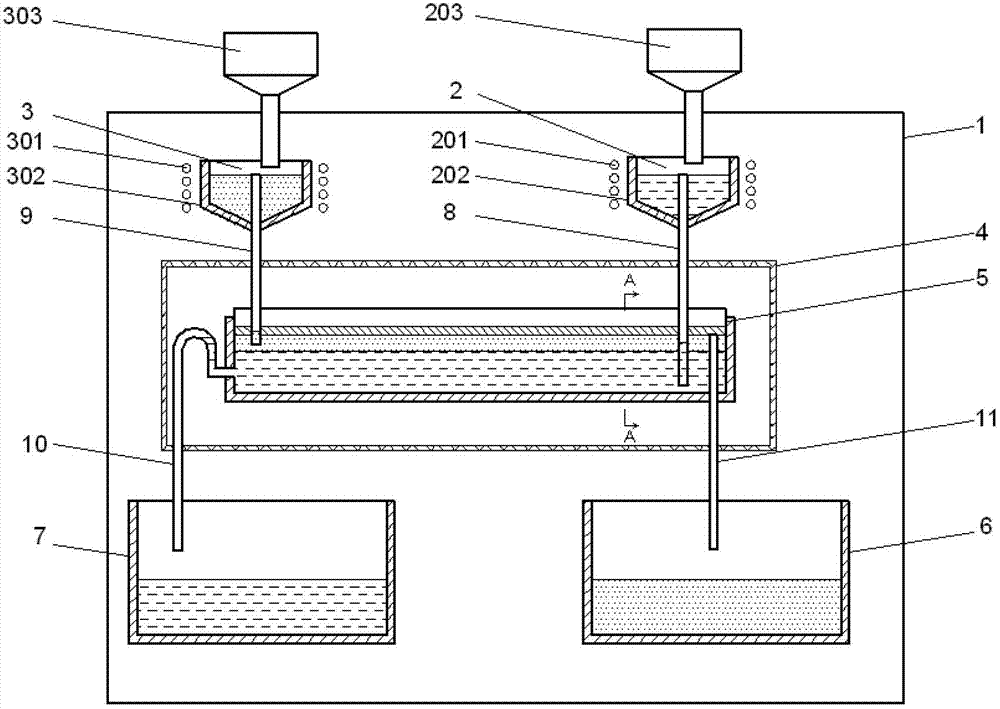

[0027] See figure 1 with figure 2, a system for preparing high-purity polysilicon by continuous slagging under an electric field, including: a silicon material melting device 2 placed in a closed cavity 1, a slagging agent melting device 3, an electromigration device 5 placed in a heat preservation cavity 4, and slag liquid Collection tank 6 and silicon liquid collection tank 7. The silicon material melting device and the electromigration device are connected through the silicon liquid injection pipe 8, the slagging agent melting device and the electromigration device are connected through the slagging agent injection pipe 9, and the purified silicon liquid in the electromigration device passes through the silicon liquid overflow pipe 10 Flowing to the silicon liquid collection tank 7, the slagging agent after absorbing impurities in the electromigration device flows to the slag liquid collection tank 6 through the slag liquid overflow pipe 11. The silicon liquid injection ...

Embodiment 2

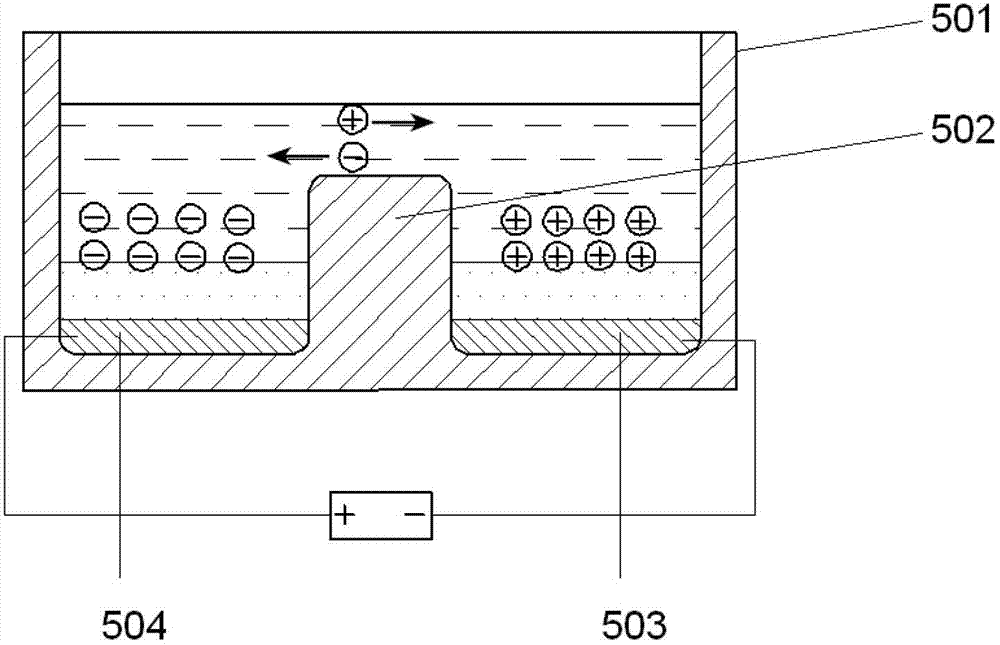

[0037] The slagging agent selects Na with a mass ratio of 4:1:5 2 O-CaO-SiO 2 For mixed molten salt, since the density of the slagging agent is smaller than that of the silicon liquid, it is necessary to use such as image 3 with Figure 4 The shown electrode is pasted on the slag liquid, and the silicon liquid is below the slag liquid. The mass ratio of the amount of slagging agent to silicon material is 1:5.

[0038] Firstly, a high-purity cathode graphite electrode plate 503 and an anode graphite electrode plate 504 are respectively arranged above the two regions of the electromigration cell, and wires are connected. The sealed cavity 1 is evacuated and the protective gas argon is introduced, and the pressure is maintained at 8000-20000Pa. Then add metal silicon material with a purity of 99.5% to the melting crucible 202 of the silicon material melting furnace through the silicon material adding hopper 203, and apply power to the intermediate frequency induction heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com