Black and white film

A black and white film, white technology, applied in the field of thin films, can solve the problem of insufficient utilization of backlight light, and achieve the effects of excellent light reflection effect, excellent molding processability, and enhanced anti-oxidation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

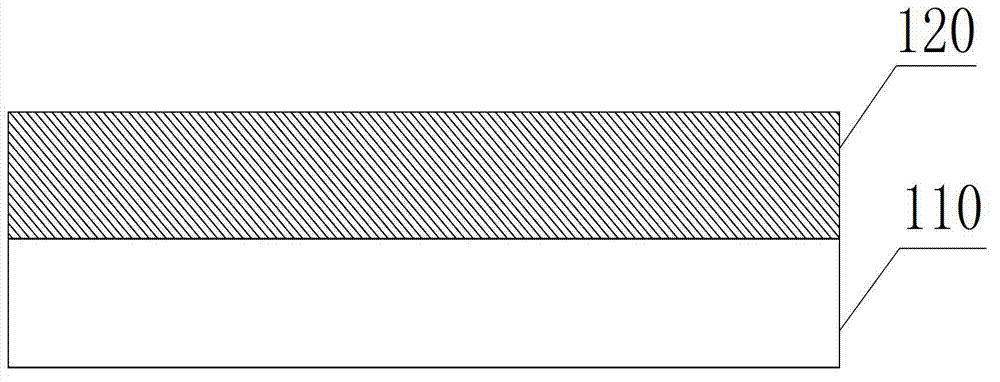

[0026] Such as figure 1 As shown, the black and white film includes a white structural layer 110 and a black structural layer 120 . The white structural layer 110 is co-extruded with the black structural layer 120 .

[0027] The white structural layer 110 is composed of engineering plastics with a mass ratio of 39% to 98.8%, a white dye with a mass ratio of 0.05% to 30%, an antioxidant with a mass ratio of 0.05% to 1%, and a mass ratio of 0.05-4 % anti-ultraviolet absorber, 0.05% to 20% flame retardant by mass ratio, 1% to 6% antistatic agent by mass ratio, and a small amount of dispersant, compatibilizer and lubricating aid.

[0028] The black structural layer 120 is composed of engineering plastics with a mass ratio of 39% to 98.8%, a black dye with a mass ratio of 0.05% to 30%, an antioxidant with a mass ratio of 0.05% to 1%, and a mass ratio of 0.05-4 % anti-ultraviolet absorber, 0.05% to 20% flame retardant by mass ratio, 1% to 6% antistatic agent by mass ratio, and a s...

Embodiment 2

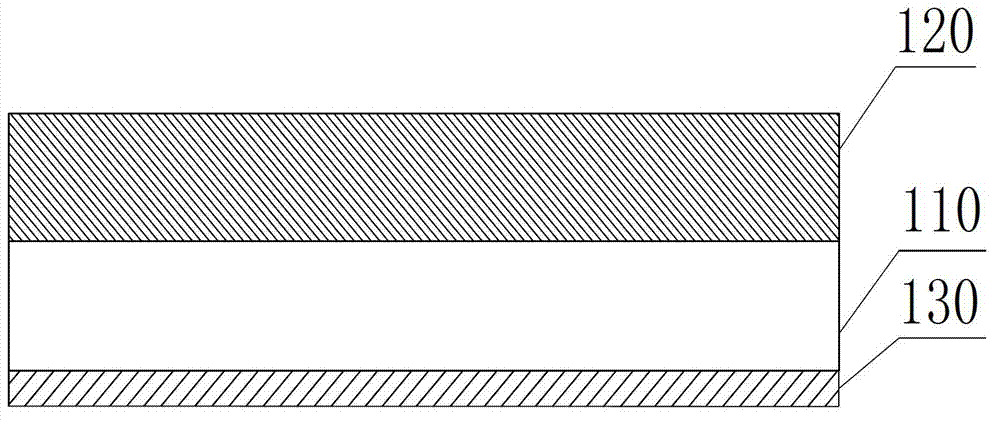

[0032] Such as figure 2 As shown, the black and white film includes a white structural layer 110 , a black structural layer 120 and an adhesive layer 130 . The white structural layer 110 is disposed between the black structural layer 120 and the adhesive layer 130, and the white structural layer 110, the black structural layer 120, and the adhesive layer 130 are formed by coating connected to each other. The adhesive layer provided in the black and white film can meet the functions of fixing, shading and light reflection of the frame of the light source of the display part, etc., and widens the application range of the black and white film. The functions and effects of other parts in this embodiment are the same as those in Embodiment 1, so they will not be repeated here.

Embodiment 3

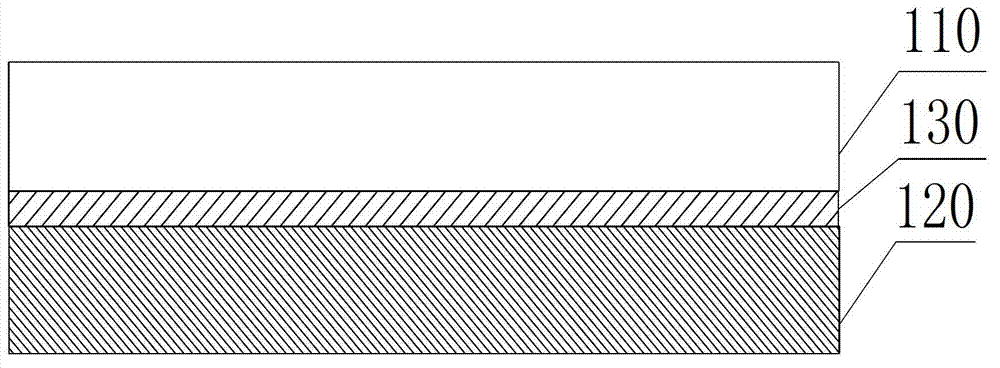

[0034] Such as image 3 As shown, the black and white film includes a white structural layer 110 , a black structural layer 120 and an adhesive layer 130 . The adhesive layer 130 is disposed between the black structural layer 120 and the white structural layer 110, and the white structural layer 110, the black structural layer 120 and the adhesive layer 130 are formed by coating connected to each other. The adhesive layer provided in the black and white film can meet the functions of fixing, shading and light reflection of the frame of the light source of the display part, etc., and widens the application range of the black and white film. The functions and effects of other parts in this embodiment are the same as those in Embodiment 2, so they will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flammability rating | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com