Process for coating diamond particles by cobalt powder

A diamond particle and coating technology, applied in diamond and other directions, can solve the problems of uneven distribution of diamond particles, affecting product quality, different specific gravity, etc., and achieve the effects of improved coating effect, low cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The process of coating diamond particles with cobalt powder includes the process of coating metal powder on the surface of diamond particles. The key is: the process steps of coating metal powder include:

[0018] a. Prepare the diluent, prepare isopropanol and acetone according to the molar ratio of (3.5-4.5): 1, and mix the prepared diluent and glue according to the weight ratio of (7-9): 1 to form an adhesive;

[0019] b. Put the diamond particles into the coating device;

[0020] c. While spraying the above-mentioned prepared adhesive into the coating device, sprinkle the metal powder into the coating device at the same time, roll and disperse the diamond particles evenly, and complete the coating process.

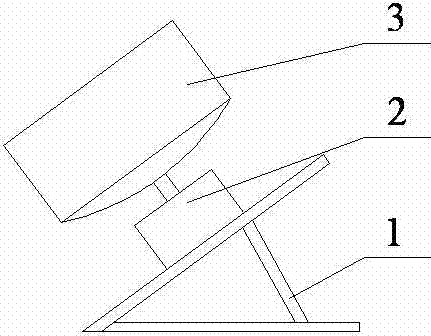

[0021] The cladding device includes a support 1, a drive motor 2 fixed on the support 1, and a container 3 containing diamonds. The container 3 is connected with the output spindle of the drive motor 2 to form a rotating structure.

[0022] The support 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com