Water-washing dust-cleaning horizontal type mesh cage dust removing machine

The technology of a horizontal ash and dust collector is applied in the field of water-washing and ash-cleaning horizontal mesh cage dust collectors. The effect of dust removal efficiency and high efficiency dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

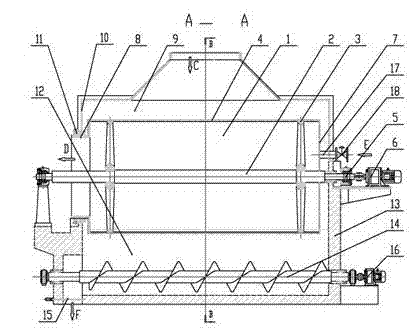

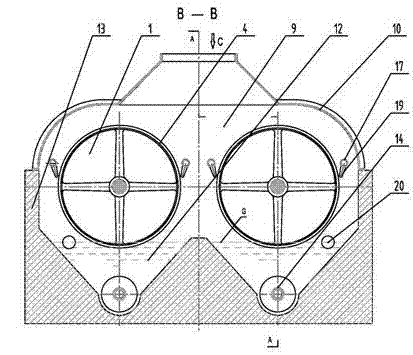

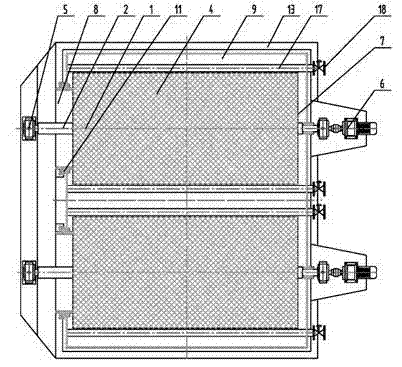

[0029] The present invention is further illustrated below in conjunction with the accompanying drawings and specific embodiments.

[0030] Such as figure 1 , figure 2 , image 3 As shown, the present invention mainly consists of a rotary cage 1; a main shaft 2; a cage skeleton 3; a filter cloth 4; a bearing seat 5; a transmission device 6; an end plate 7; ; Sealing device 11; V-shaped tank 12; box 13; mud screw 14; sewage valve 15; screw drive 16; spray water pipe 17;

[0031] The rotating net cage 1 is composed of the main shaft 2, the net cage frame 3, the filter cloth 4, the bearing seat 5, the transmission device 6, the end plate 7 and the exhaust port 8. The dust collection chamber 9 is composed of an upper casing 10 , a sealing device 11 , a V-shaped water tank 12 and a box body 13 . The sewage device is composed of a mud discharge screw 14, a sewage valve 15, a screw drive 16 and the like. The water mist spray washing device is made up of spray water pipe 17, auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com