Wing-shaped infusion needle connection seat

A connecting seat and infusion needle technology, which is applied in the field of medical devices, can solve the problems of no installation, low production efficiency, and a small number of single injection molding parts, and achieve the effects of easy production, improved production, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below, illustrate the implementation of the present invention in conjunction with accompanying drawing:

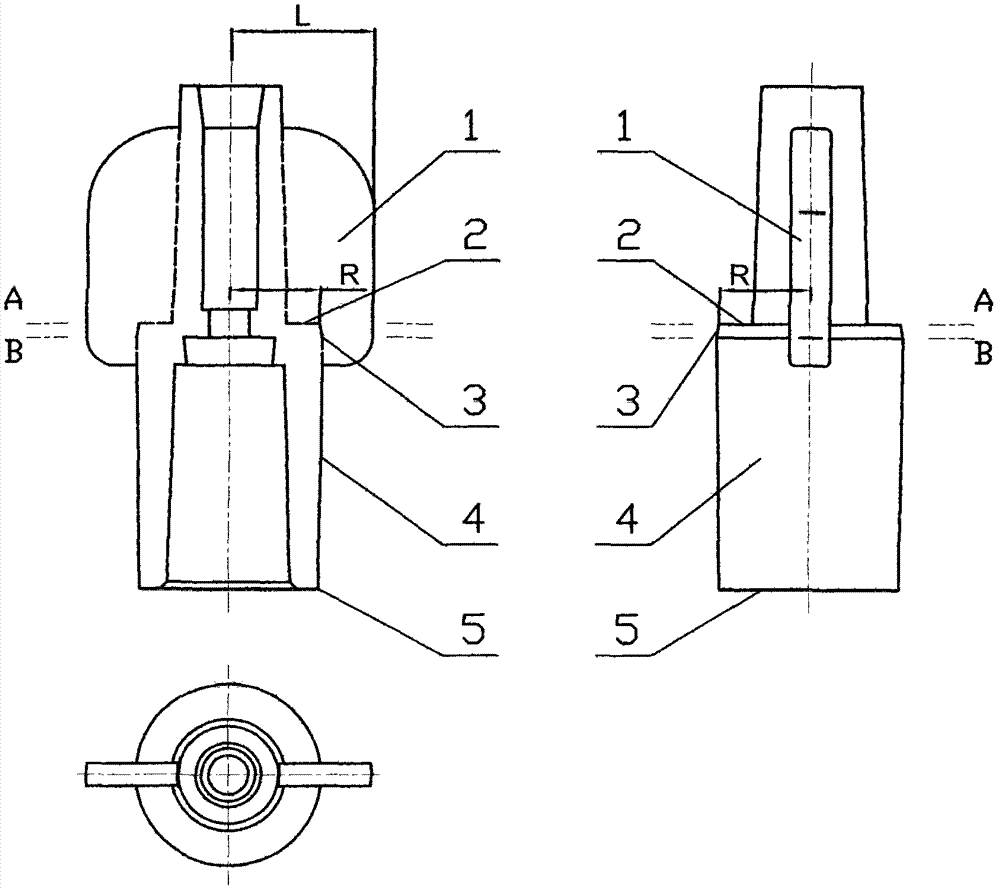

[0009] When the extension width L of the wing (1) is not less than the radius R of the bottom (2) of the connecting seat body (4), the outer circumference diameter of the rear end of the seat body (3) is not less than the outer circumference diameter of the seat body port (5), The parting surface of the connecting seat is located between the widest extension of the wing (1) and the bottom (2) of the seat body (4), that is, between the A surface and the B surface, so that the plastic is axially demoulded after injection molding in the mold. Therefore, when the mold is made, it can be arranged in double rows or multiple rows, and the number of single injection molding parts is relatively large, so that it can be convenient for medical staff to tighten the connecting seat and the infusion set connector during clinical use. , and greatly improve the production efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com