Chinese medicine composition with effect of alleviating asthenopia and preparation method thereof

A technology of visual fatigue and composition, which is applied in the field of traditional Chinese medicine, can solve problems such as unsatisfactory effects, and achieve the effects of relieving visual fatigue and improving microcirculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

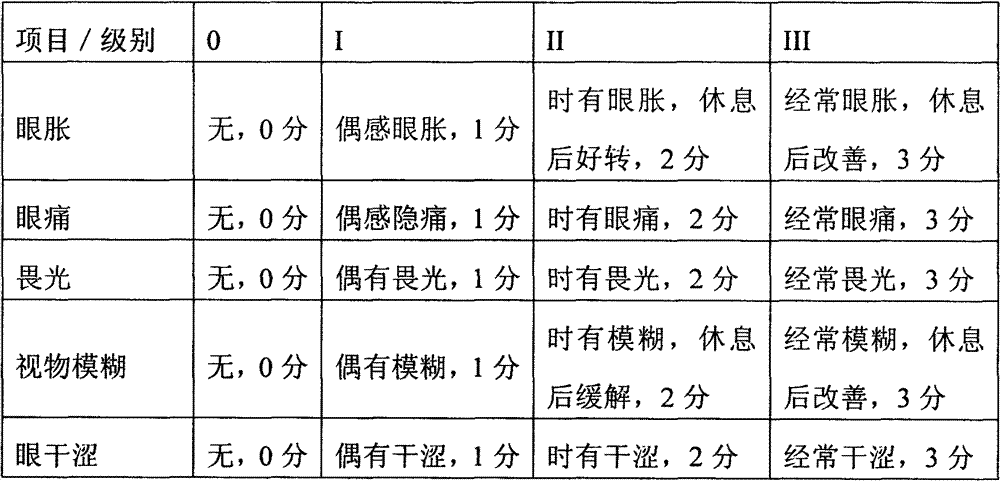

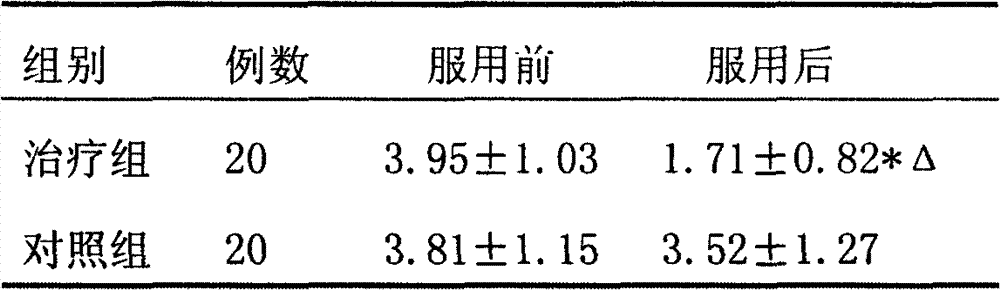

Image

Examples

Embodiment 1

[0015] Example 1 Preparation of tablets of the present invention

[0016] Weigh the raw materials according to the following weight ratio: 120 grams of Bichengqi, 90 grams of Golden Grass 90 grams, 120 grams of Acanthopanax 120 grams, and 120 grams of Violaea. Add the above weight ratio to 8-10 times the total amount of raw materials, soak in water for 1.5 hours, heat and cook for 1.5 hours, filter, add 8 times the amount of water to the dregs, heat and cook for 1 hour, filter, and combine the filtrate to get the supernatant When the supernatant is concentrated to a relative density of 1.06, it enters the spray dryer, the inlet air temperature is controlled at 140°C, the outlet temperature is 110°C, and the feed rate is 5ml / min. 22 grams of spray-dried powder and crushed spray-dried powder Into a fine powder. The above-mentioned fine powder is made into granules by adding auxiliary materials according to the conventional process, dried, and compressed.

Embodiment 2

[0017] Example 2 Preparation of capsules of the present invention

[0018] Weigh each of the raw materials according to the following weight ratio: 50 parts of Bichengqi, 50 parts of C. chinensis, 50 parts of Acanthopanax and 50 parts of Viola didin. Add the above weight ratio to 8-10 times the total amount of raw materials, soak in water for 1.5 hours, heat and cook for 1.5 hours, filter, add 8 times the amount of water to the dregs, heat and cook for 1 hour, filter, and combine the filtrate to get the supernatant When the supernatant is concentrated to a relative density of 1.06, enter the spray dryer, the inlet air temperature is controlled at 140°C, the outlet temperature is 110°C, and the feed rate is 5ml / min. 10g of spray-dried powder is obtained, and the spray-dried powder is crushed Into a fine powder. The above-mentioned fine powder is added with auxiliary materials according to the conventional process, mixed evenly, and filled into hard gelatin capsules.

Embodiment 3

[0019] Example 3 Preparation of capsules of the present invention

[0020] Weigh the raw materials according to the following weight ratios: 300 grams of Bichengqi, 300 grams of Golden Grass, 300 grams of Acanthopanax 300 grams, and 300 grams of Viola frondosa.

[0021] Weigh each of the raw materials according to the following weight ratio: 300 parts of Bichengqi, 300 parts of Golden Grass 300 parts, 300 parts of Acanthopanax, 300 parts of Viola tricolor. Add the above weight ratio to 8-10 times the total amount of raw materials, soak in water for 1.5 hours, heat and cook for 1.5 hours, filter, add 8 times the amount of water to the dregs, heat and cook for 1 hour, filter, and combine the filtrate to get the supernatant When the supernatant is concentrated to a relative density of 1.06, it enters the spray dryer, the inlet air temperature is controlled at 140°C, the outlet temperature is 110°C, and the feed rate is 5ml / min. 60 grams of spray-dried powder is obtained, and spray-dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com