Combined type three-dimensional heat radiation structure fully utilizing heat radiation space for light-emitting diode (LED) and method

A technology for LED lamps and heat dissipation structures, which is applied to semiconductor devices of light-emitting elements, lighting and heating equipment, cooling/heating devices for lighting devices, etc. The effect of the total cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further elaborated below in conjunction with accompanying drawings, and its shape and structure can be realized by those skilled in the art.

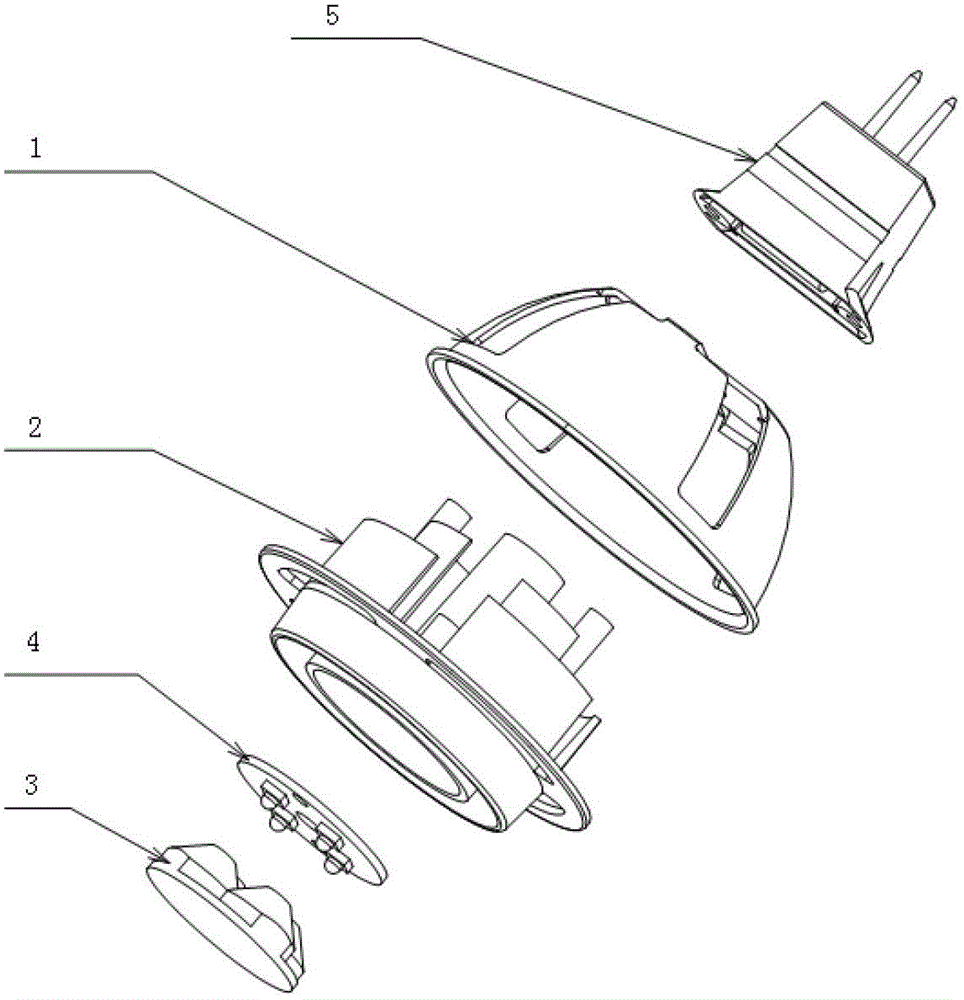

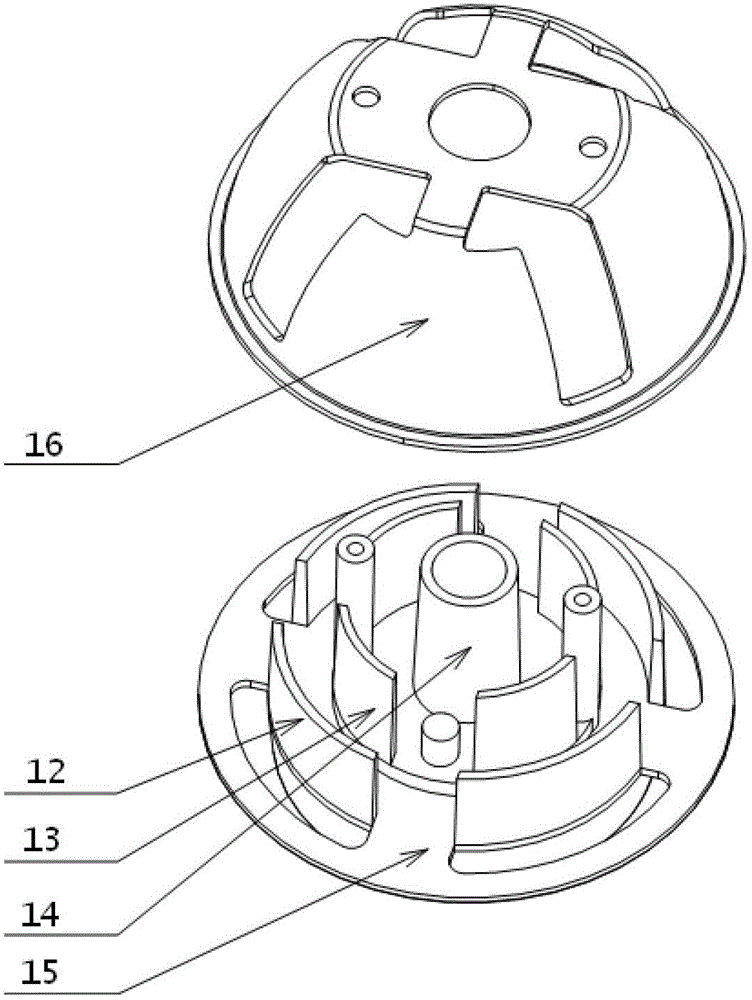

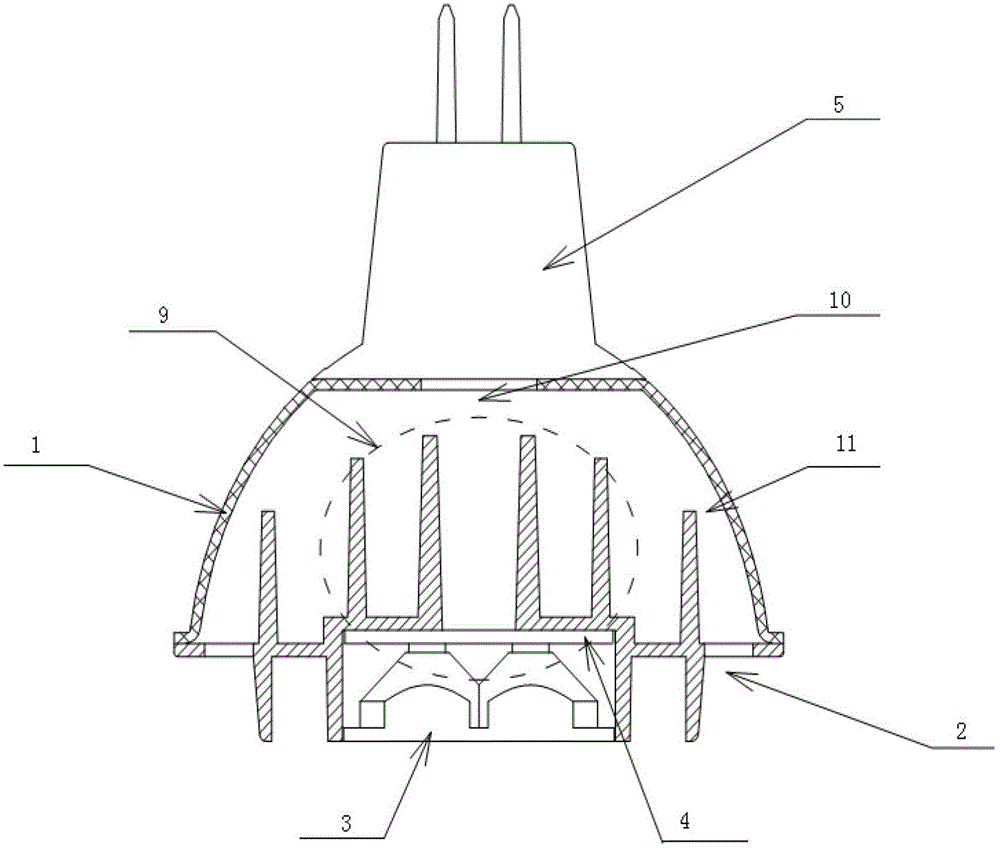

[0045] The traditional MR16 LED lamp is composed of an external radiator or an internal radiator (in this example, a cooling cup 17 is selected), a lens 18, an LED display board 19, a lamp interface and a power supply box 20. Figure 4 Connect and install as shown, the heat dissipation part is as follows Figure 5 As shown, fan-shaped heat sinks surround the heat dissipation cup 17 at equal intervals, and the heat dissipation area formed is: (heat dissipation surface 21 + heat dissipation surface 22 + heat dissipation surface 23 + heat dissipation surface 24 + heat dissipation surface 25) * 18 = 6500 square millimeters, traditional heat dissipation Inside the device such as Figure 6 The cavity shown is solid or the power supply is placed, which cannot be used, resulting in uneven heat dissipation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com