Gearbox steering mechanism

A steering mechanism and gearbox technology, applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of frequent use of steering mechanism, complex processing of intermediate gears, low production efficiency of parts, etc., and achieve novel structure, The effect of large transmission torque and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

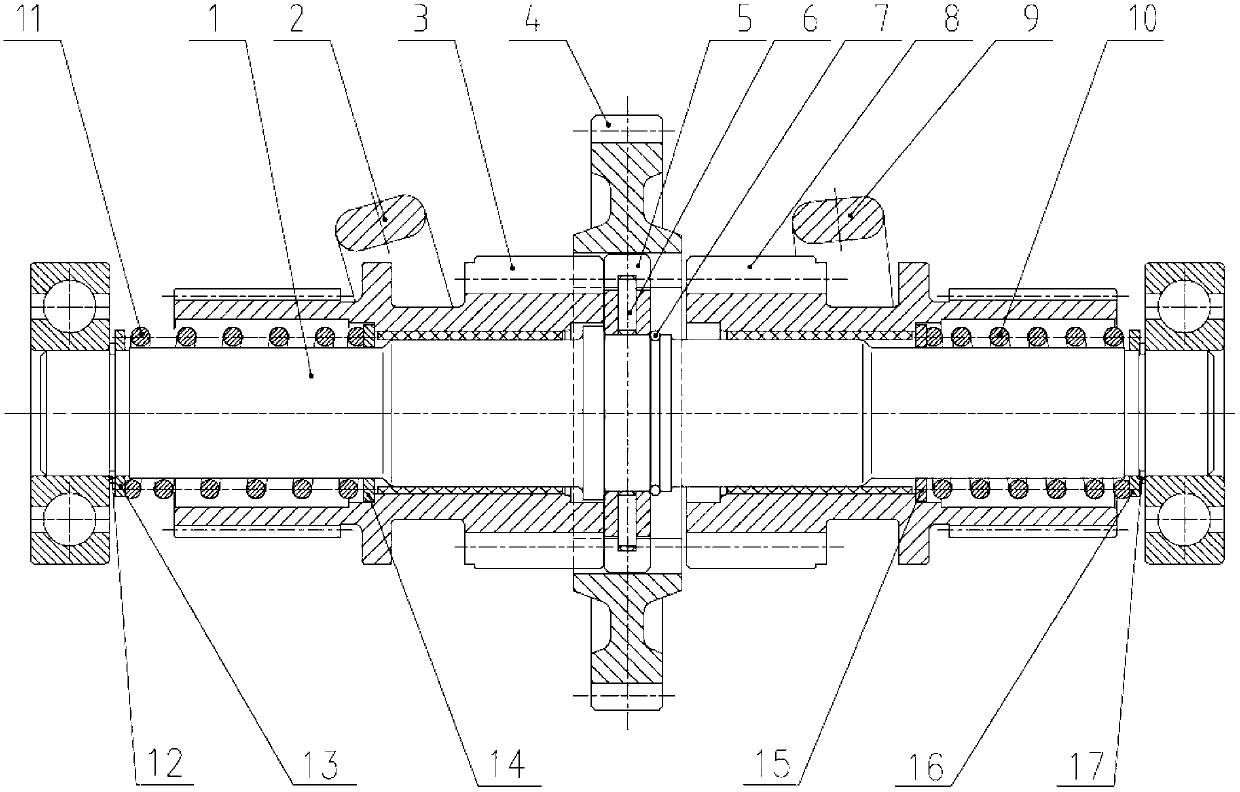

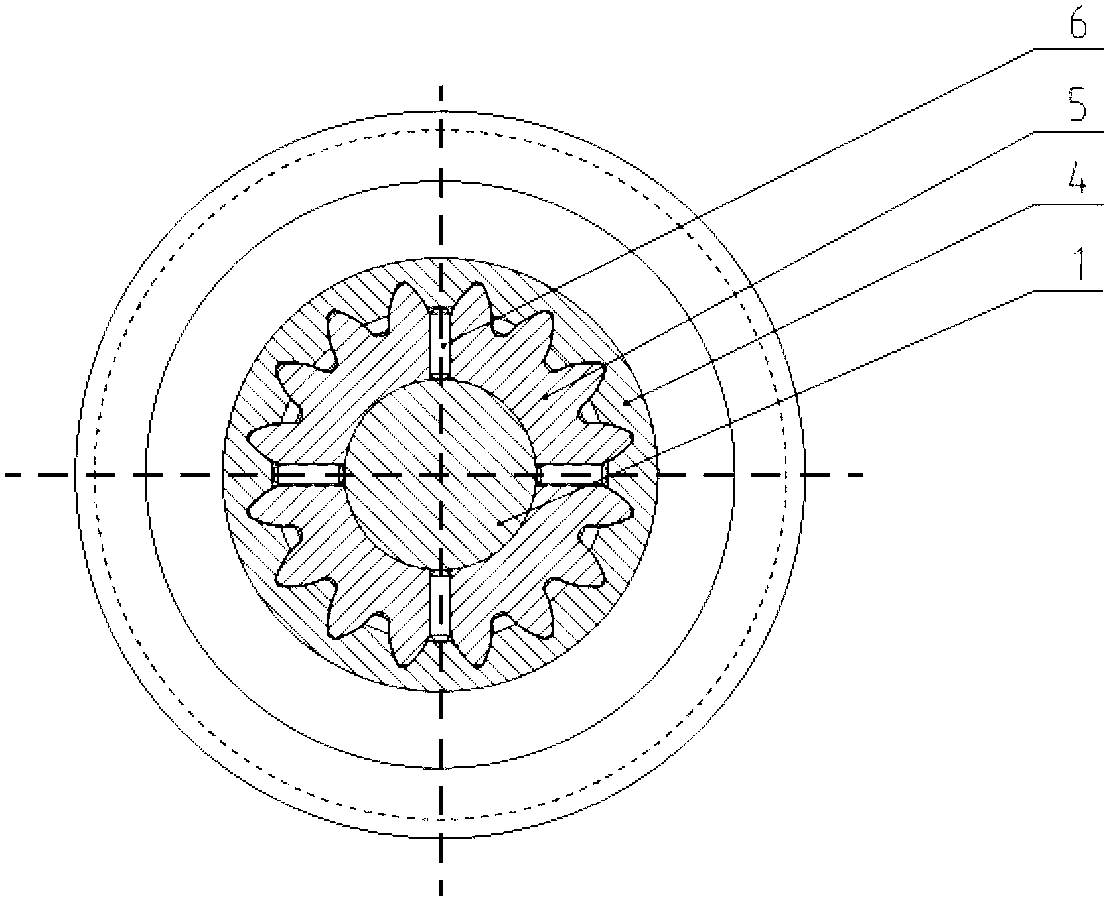

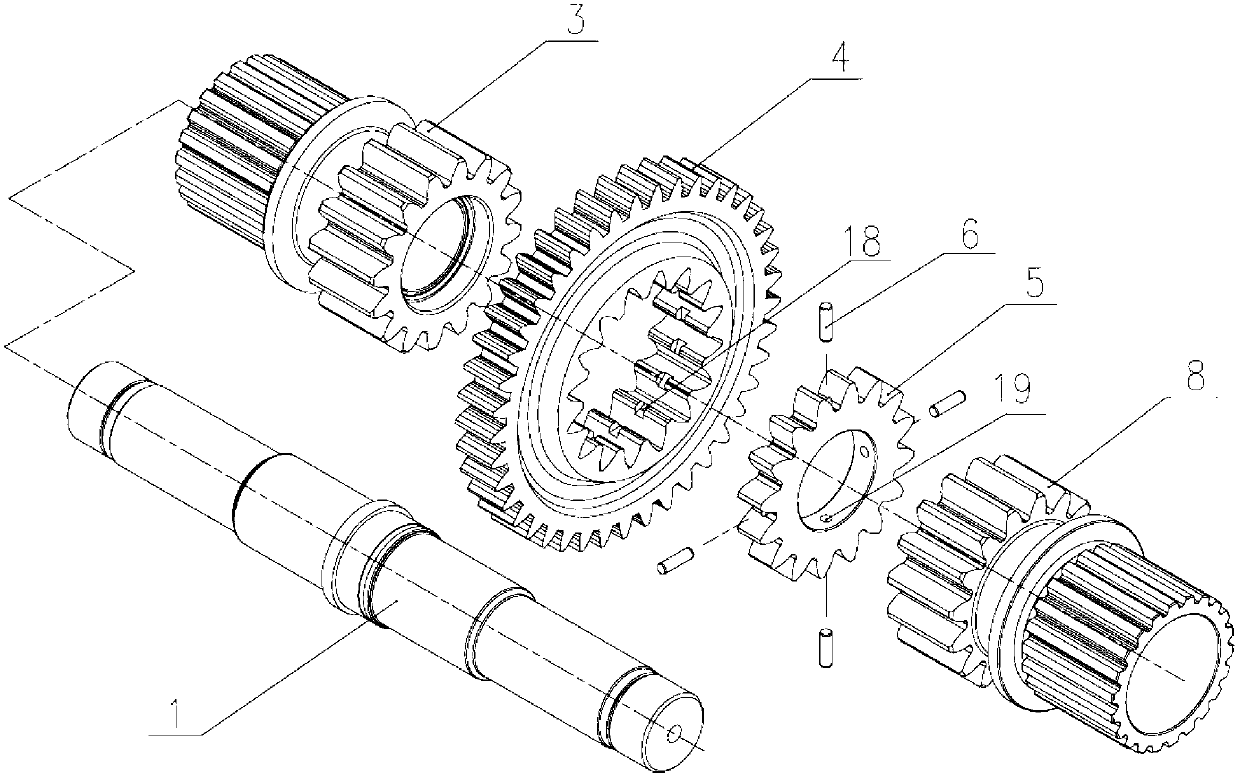

[0029] The accompanying drawings disclose the specific structure of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as Figure 1~4 As shown, the gearbox steering mechanism includes a steering shaft 1, which is coaxially arranged on the steering shaft 1 and has an intermediate gear 4 with internal teeth; the steering shaft 1 on both sides of the intermediate gear 4 is slidingly sleeved with left and right steering gears respectively. Gears 3 and 8; one side of the left and right steering gears 3 and 8 is provided with large teeth meshing with the internal teeth of the intermediate gear 4, and the other side is provided with small teeth; correspondingly provided on the left and right steering gears 3 and 8 Left and right steering forks 2, 9; left and right return springs 11, 10 are sleeved at both ends of the steering shaft 1; a coupling gear 5 is coaxially fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com