Variable cross-section high supersonic speed inward rotation type air inlet with consistency of local contraction ratio

An internally rotating air inlet, hypersonic technology, applied in the air inlet of the turbine/propulsion unit, combustion air/combustion-air treatment, engine components, etc. The difference between the inlet/outlet aspect ratio should not be too large, so as to achieve the effect of uniform flow field and broaden the working range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

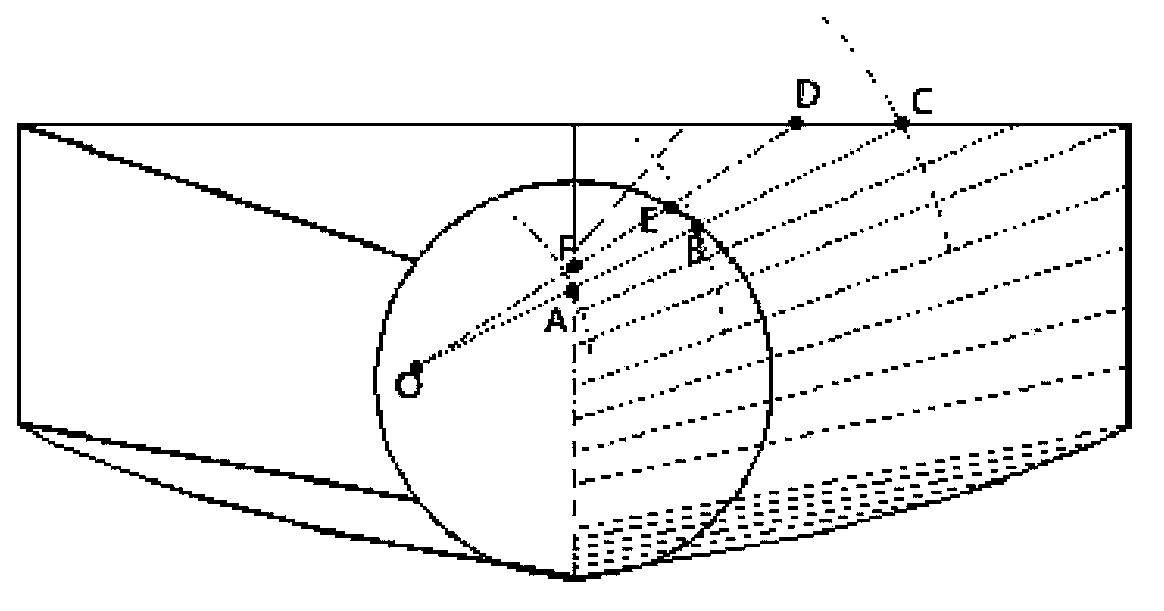

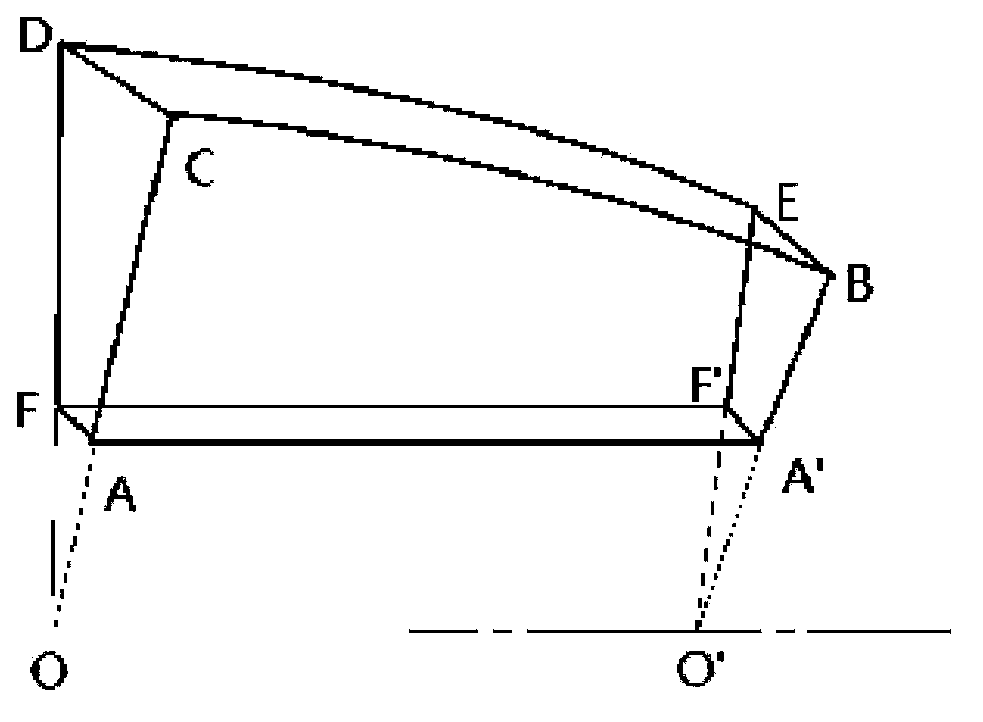

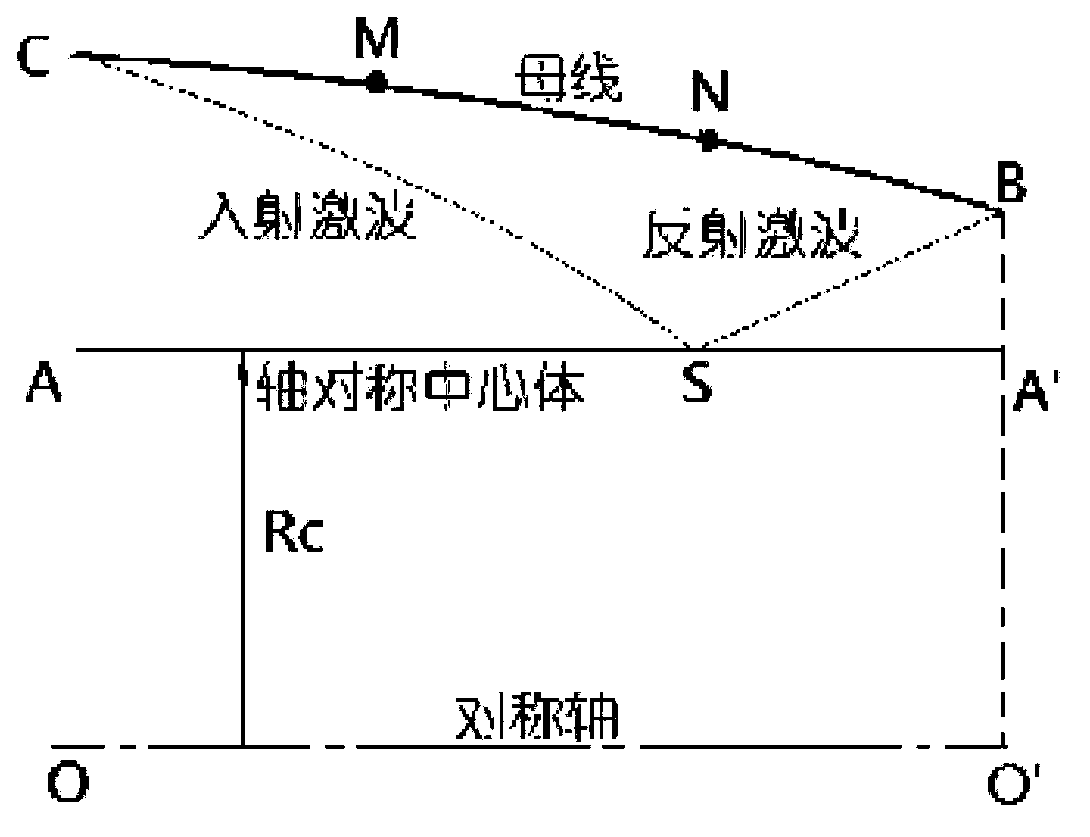

[0030] The Mach number of the incoming flow is 6.5, given the inlet and the Picture 1-1For the inlet and outlet shapes shown, the design requirements of the inlet are that the inlet width-to-height ratio is 2.43, the outlet is a perfect circle, and the total shrinkage ratio is 3.53. The flow field according to Picture 1-1 Divided in the manner shown, for each sub-flow tube where the Figure 1-3 The profile design of the axisymmetric flow field shown is carried out. The design method adopts the pattern search algorithm in the Matlab optimization toolbox combined with the computational fluid dynamics program to obtain the profile that makes the sub-flow tubes absorb waves, and all the sub-flow tubes are overlapped according to the reflected shock wave. The principle of recombination, the outer contour of each sub-flow tube forms the inlet profile. diagram 2-1 , Figure 2-2 , Figure 2-3 , Figure 2-4 is the three-dimensional profile of the inlet. At the design Mach number,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com