Compound forming method of multi-layered knitted fabric made of multi-component raw materials

A composite molding and knitted fabric technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of poor fit, lack of elasticity, environmental pollution, etc., and achieve high fit comfort and production process. Short, lofty results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

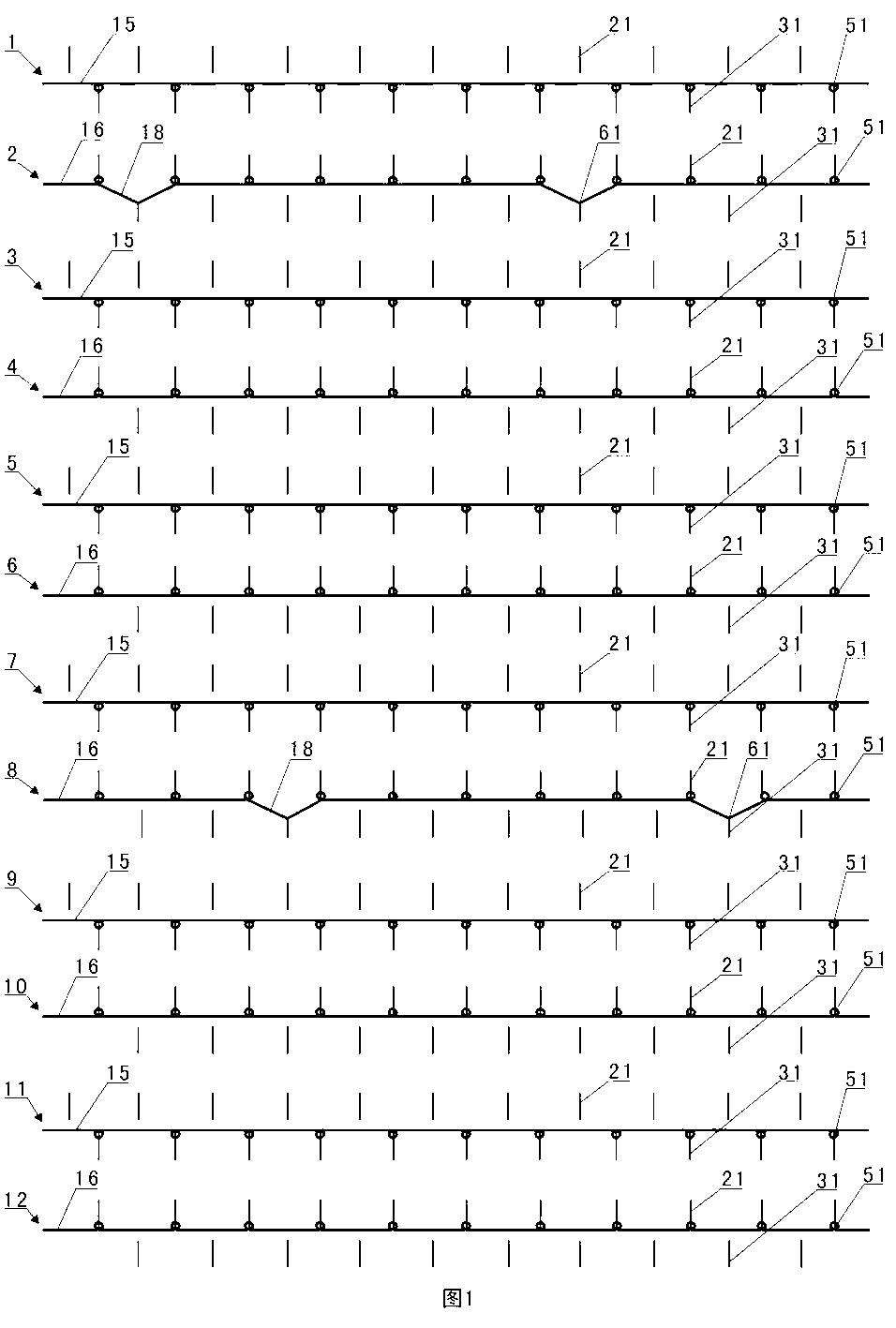

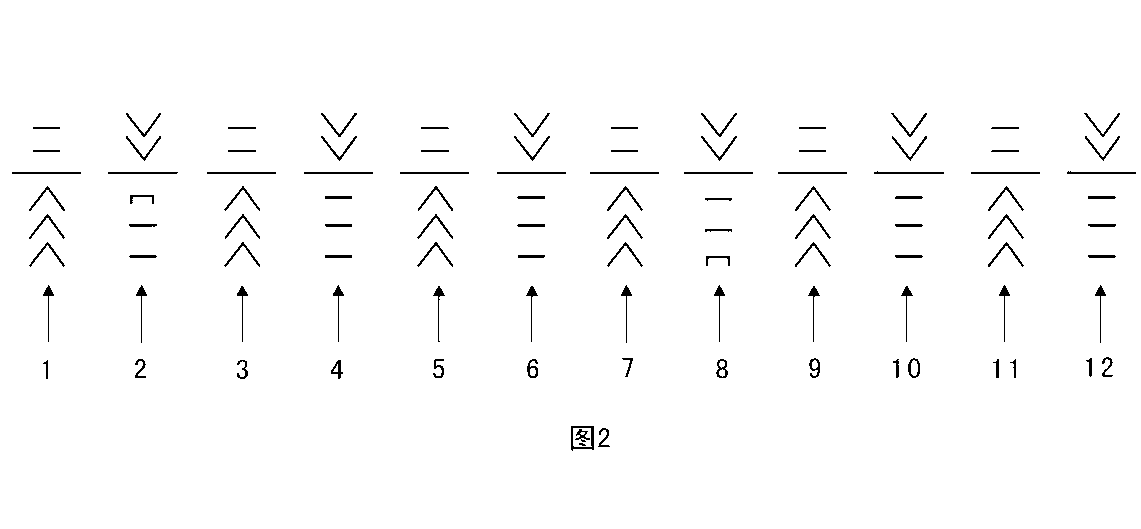

[0022] Such as figure 1 As shown, taking the processing of thermal cotton as an example, three raw materials are used: the clothing front of the fabric uses T / C raw material 15 to ensure that the fabric has a smooth appearance, bright colors, and stable dimensions. It is made by single-sided weaving. Completed; the reverse side of the fabric is made of pure cotton material 16 to ensure that the fabric has good moisture absorption, warmth, and personal comfort. It is completed by the selective cooperation of single-side weaving and tuck weaving; the middle interlayer The polyester fiber raw material 18 with great elasticity and bulkiness is used to increase the thickness, three-dimensionality and warmth retention of the fabric. On the double-layer weft knitting circular knitting machine (not shown in the figure), the above three raw materials are input through different weaving systems, and different yarn feeding tensions are used during the input process.

[0023] Such as fi...

Embodiment 2

[0027] Such as Figure 4 As shown, taking the processing of French rib as an example, two kinds of raw materials are used: for the front of the fabric, 30 yarns with a yarn length of 28cm / 100N are used. s BJ raw material 81; the reverse side of the fabric, use 30 with a yarn length of 30cm / 100N s T raw material 82; interlayer yarn length 28cm / 100N 30 s T Raw 83. On the double-layer weft knitting circular knitting machine (not shown in the figure), the above three raw materials are input through different weaving systems, and different yarn feeding tensions are used during the input process.

[0028] Such as Figure 4 As shown, in the processing of French rib, the same cycle is divided into 8 weaving systems, which are the first weaving system A, the second weaving system B, the third weaving system C, the fourth weaving system D, the fifth weaving system E, The sixth weaving system F, the seventh weaving system G, and the eighth weaving system H.

[0029] Such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com