Ultrahigh-speed air jet loom

An air-jet loom, ultra-high-speed technology, used in looms, textiles, textiles and papermaking, etc., can solve the problems of ultra-high-speed operation that cannot exceed 1000 rpm, and achieve high air pressure, shortened air paths, and high weaving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

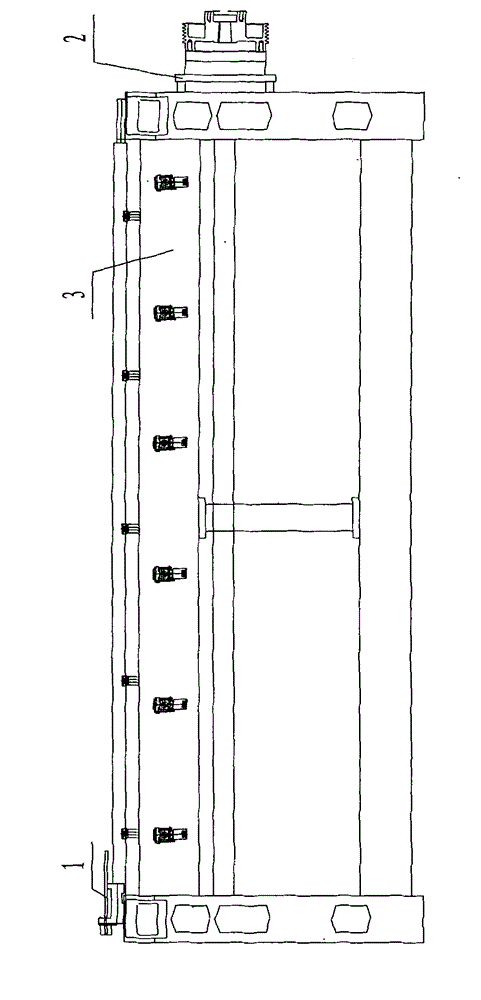

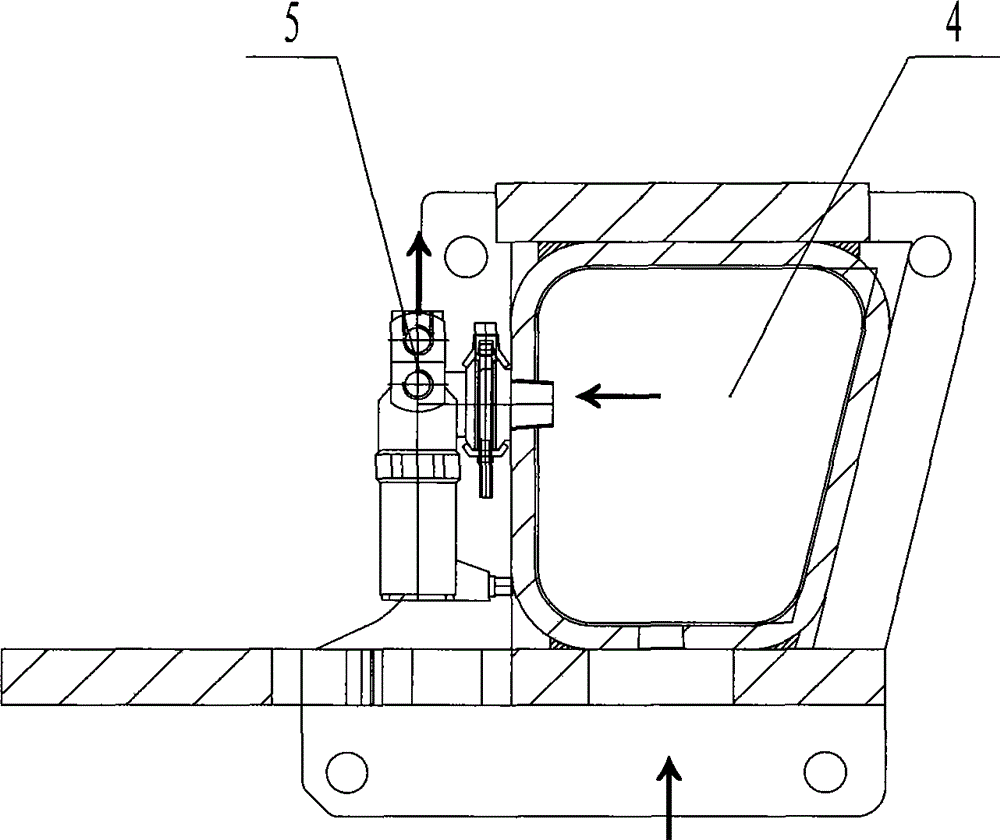

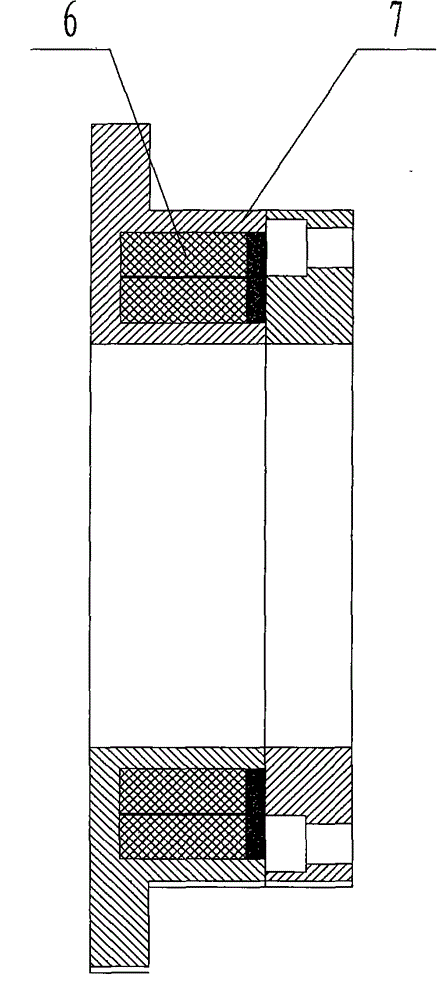

[0019] As shown in the figure, the ultra-high-speed air-jet loom includes main nozzle 1, brake disc 2, and air bag 3 without air path. The main nozzle 1, brake disc 2, and air bag 3 without air path On the main engine of the machine, wherein, the airless air bag 3 includes a solenoid valve 5 and an air bag 4, wherein the electromagnetic valve 5 is arranged on the air bag 4, and two groups of electromagnetic coils 6 are arranged on the fixed disk 7 of the brake disc 2; At least six electromagnetic valves 5 are arranged on the air bag 3; the diameter of the main nozzle 1 is 2.15mm, and the length is changed to 42.15mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com