Pre-loosing pull yarn tray used for automatic doffer

A technology of automatic doffing and yarn tray, which is applied in the direction of textiles and papermaking, can solve the problems of cotton yarn damage, surface deformation, etc., and achieve the effects of avoiding damage, good physical properties, and accurate working process

Inactive Publication Date: 2012-10-10

JINGWEI TEXTILE MASCH CO LTD

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing doffing machines of the same kind use traditional hard phenolic resin laminates or stainless steel plates to make the pre-loosening disc. damage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

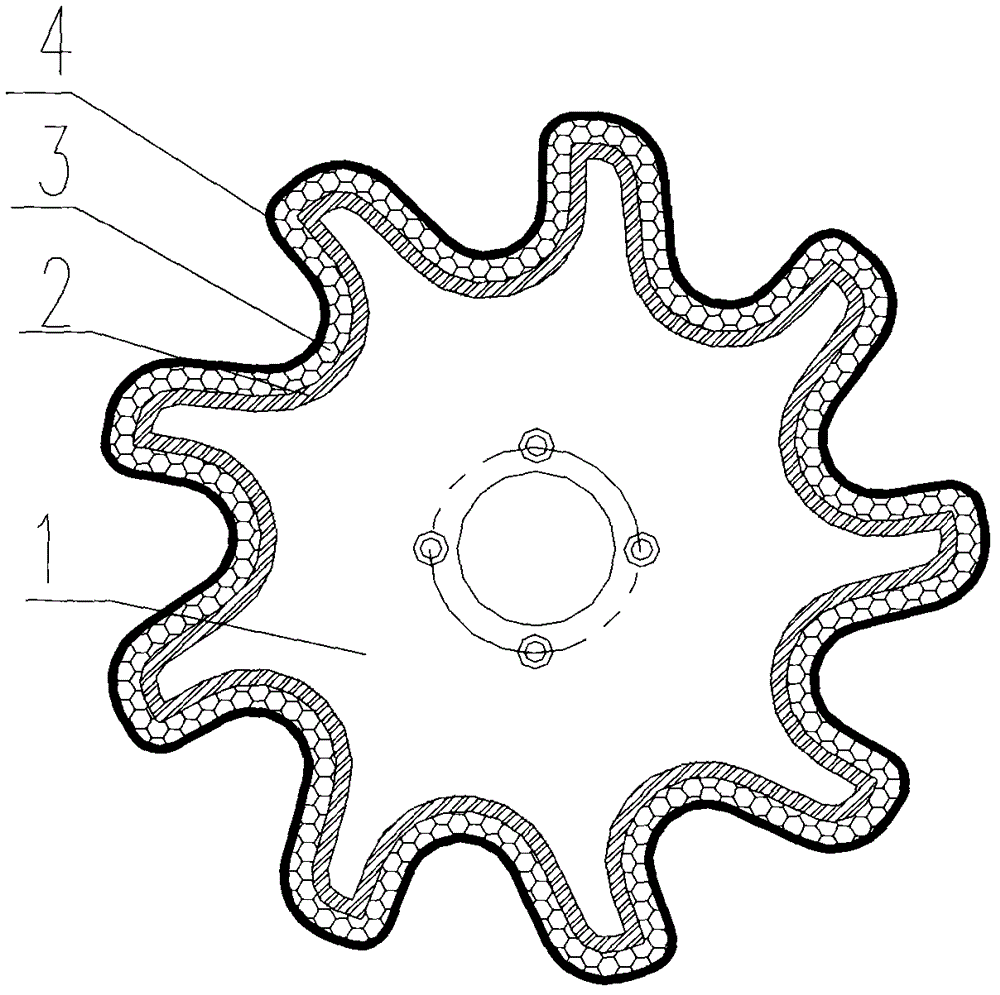

The invention specifically relates to a pre-loosing pull yarn tray used for an automatic doffer. The pull yarn tray comprises a baseplate (1), a skeleton plate (2), a gripping body (3), and an outer edge (4), wherein the skeleton plate (2) is arranged outside of the baseplate (1), the gripping body (3) is arranged outside of the skeleton plate (2), and the outer edge (4) is arranged outside of the gripping body (3); an engineering material adopted by the baseplate (1) is a phenol formaldehyde resin, an engineering material adopted by skeleton plate (2) is a polyurethane elastic body, an engineering material adopted by the gripping body (3) is solid silicone rubber, and an engineering material adopted by the outer edge (4) is a double layer spandex coating leather. The device enables the working process of the pull yarn of the doffer to be more exact and reliable, can greatly lighten and avoid damage on spun cotton and impulsion on a thread spinning spindle when the common type doffer pulls out yarn, expands the applicability of a moveable doffer, and realizes automatic control.

Description

technical field [0001] The invention belongs to a mobile doffing machine used for doffing of a ring spinning machine, and in particular relates to a pre-loosening and drawing disc used for an automatic doffer. Background technique [0002] my country's textile enterprises have long used manual doffing, and some manufacturers with high technical level use a mobile and simple auxiliary machine called "doffing trolley" to help workers complete the doffing process. This type of device has various types, simple structure, and low cost, but one of the main problems is that when spinning high-grade cotton yarn, the pre-drawing disc of rigid material will cause small damage to the cotton yarn, which needs to be improved and perfected urgently. The existing doffing machines of the same kind use traditional hard phenolic resin laminates or stainless steel plates to make the pre-loosening disc. damage. Contents of the invention [0003] The technical problem to be solved by the pre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D01H9/02D01H9/10

Inventor 赵镇尧杨端秀

Owner JINGWEI TEXTILE MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com