Method for preparing methyl cellulose ether with arundodomax dissolving pulp serving as raw material

A technology of methyl cellulose ether and dissolving pulp, which is applied in the field of preparation of methyl cellulose ether, can solve the problems of increased production cost of cellulose ether, increased burden on enterprises, high equipment cost, etc., and achieves remarkable environmental protection effect and reduces The effect of waste liquid and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Method for producing methyl cellulose ether from reed bamboo dissolving pulp:

[0053] (a). In 100 parts of 95% ethanol, 10 parts of sodium hydroxide, heat to dissolve the sodium hydroxide, add 20 parts of Arundis dissolving pulp powder, stir and alkalize at 20°C for 3 hours to make sodium cellulose .

[0054] The particle size of Arundis dissolving powder is 200μm;

[0055] The parts by weight of components are:

[0056] 100 parts of ethanol with a volume concentration of 95%

[0057] 20 parts of Arundis dissolving powder

[0058] Sodium hydroxide 10 parts

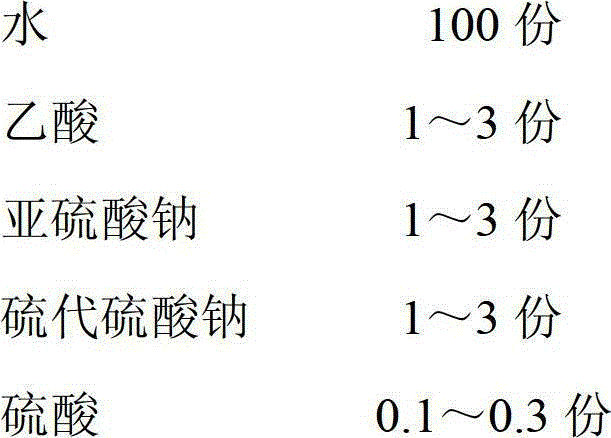

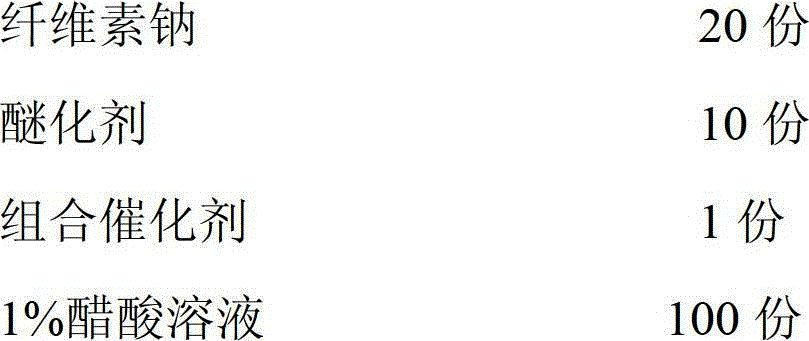

[0059] (b). Add an etherification agent to the cellulose sodium, and in the presence of the combination catalyst, etherify at 45°C for 2 hours, then separate the reaction liquid and recover the combination catalyst, and use a weight concentration of 95°C Soak 100 parts of 1% acetic acid solution for 30 minutes, then remove the acid solution with a centrifuge;

[0060]

[0061] Described etherifying agen...

Embodiment 2

[0086] 1. Method for producing methyl cellulose ether from reed bamboo dissolving pulp:

[0087] (a). Add 15 parts of sodium hydroxide to 100 parts of 85% ethanol, heat to dissolve the sodium hydroxide, add 30 parts of Arundis dissolving pulp powder, stir and alkalize at 40°C for 2 hours to make sodium cellulose .

[0088] The particle size of Arundis dissolving pulp powder is 300μm;

[0089] The parts by weight of components are:

[0090] 100 parts of ethanol with a volume concentration of 85%

[0091] 30 parts of Arundis dissolving pulp

[0092] Sodium hydroxide 15 parts

[0093] (b). Add the cellulose sodium into the etherifying agent, and in the presence of the combined catalyst, etherify at 45°C for 1 hour, then separate the reaction liquid and recover the combined catalyst, and use a weight concentration of 95°C as Soak 100 parts of 0.5% sulfuric acid solution for 60 minutes, then remove the acid solution with a centrifuge;

[0094]

[0095] Described etherifyin...

Embodiment 3

[0119] One, the method for producing methyl cellulose ether from reed bamboo dissolving pulp, by the following steps:

[0120] (a). Add 12.5 parts of sodium hydroxide to 100 parts of 75% ethanol, heat to dissolve the sodium hydroxide, add 25 parts of reed bamboo dissolving pulp powder, stir and alkalize at 30°C for 2.5 hours to make sodium cellulose .

[0121] The particle size of Arundis dissolving powder is 250μm;

[0122] The parts by weight of components are:

[0123] 100 parts of ethanol with a volume concentration of 75%

[0124] 25 parts of Arundis dissolving powder

[0125] Sodium hydroxide 12.5 parts

[0126] (b). Add the cellulose sodium into the etherification agent, and in the presence of the combined catalyst, etherify at 45°C for 2 hours, then separate the reaction liquid and recover the combined catalyst, using a weight concentration of 1 at 95°C 100 parts of acetic acid solution soaked for 45 minutes, then removed the acid solution with a centrifuge;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com