Preparation method of composite silicon carbide ceramic filter membrane material

A technology of ceramic filter membrane and composite silicon carbide, which is applied in the field of high-temperature dust removal gas, can solve the problems of long time consumption, complicated preparation process, and high energy consumption, and achieve the effects of high efficiency, simple process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

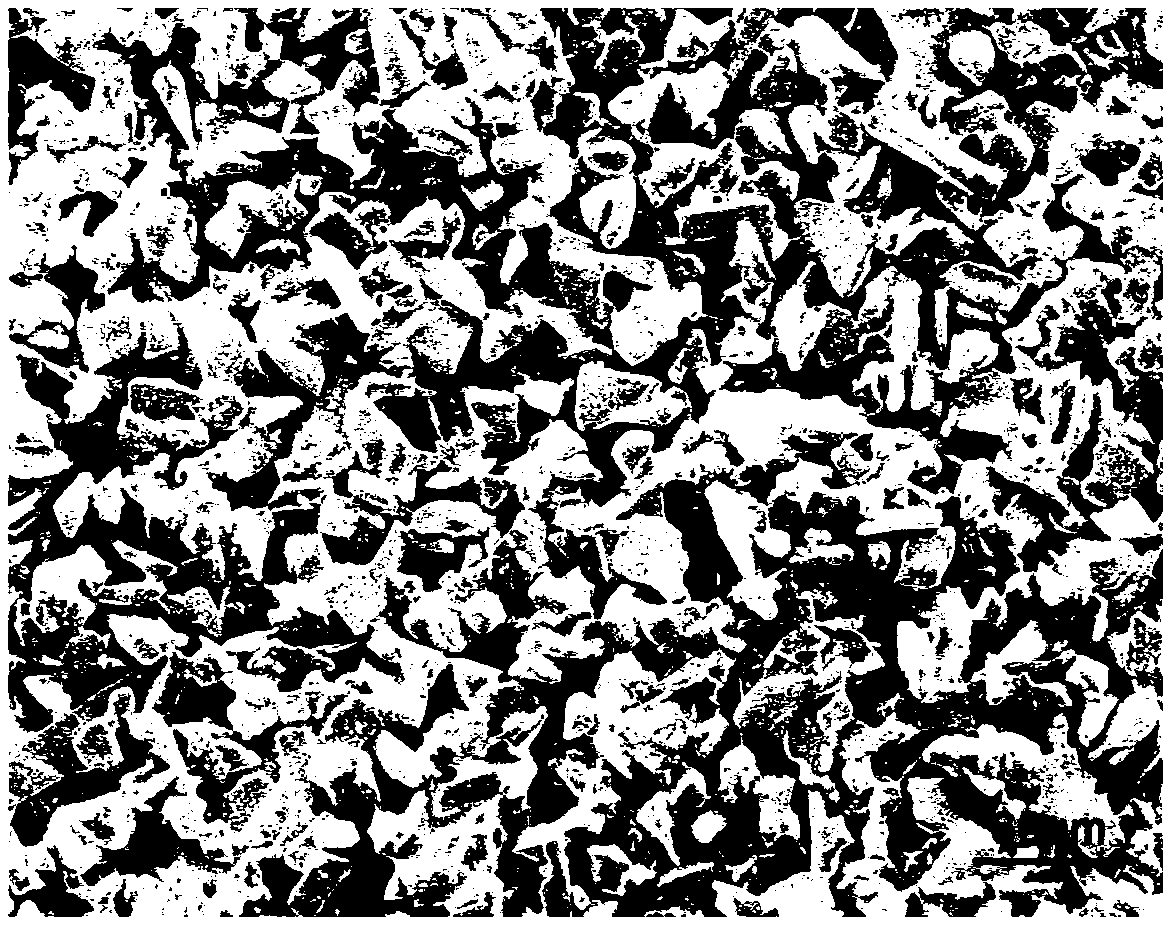

Image

Examples

Embodiment 1

[0026] 1. According to the mass fraction of 65wt% potassium feldspar, 12wt% kaolin, and 23wt% quartz, the potassium feldspar, kaolin and quartz are mixed and ball-milled until the particle size is 0.1-3 μm to obtain a ceramic binder.

[0027] 2. Weigh 10g of silicon carbide particles, 1.11g of ceramic binder, 1.33g of activated carbon (particle size 3μm) and 1.5g of carboxymethyl cellulose (CMC) solution with a mass fraction of 2wt%; first add silicon carbide particles CMC solution, and stir evenly; Then ceramic binder and activated carbon are added respectively, and after stirring until uniform, weigh its 4g mixture and dry-press molding, the pressure is about 26MPa, obtains the SiC porous ceramic support green body, The diameter is 20mm and the thickness is about 5mm. The average particle size of the silicon carbide particles is 300 μm.

[0028] 3. Scatter and spread a layer of activated carbon powder (particle size: 3μm.) on the surface of the support body, and dry press i...

Embodiment 2

[0034] 1. Same as step (1) in Embodiment 1.

[0035] 2. Weigh 10g of silicon carbide particles, 1.85g of ceramic binder, 2.13g of activated carbon (particle size 4μm) and 1.9g of carboxymethyl cellulose (CMC) solution with a mass fraction of 3wt%; first add silicon carbide particles CMC solution, and stir evenly; Then ceramic binder and activated carbon are added respectively, and after stirring until uniform, weigh its 4g mixture and dry-press molding, the pressure is about 26MPa, obtains the SiC porous ceramic support green body, The diameter is 20mm and the thickness is about 5mm. The average particle size of the silicon carbide particles is 250 μm.

[0036] 3. Scatter and spread a layer of graphite powder (particle size: 0.7μm.) on the surface of the support body, and dry press it with a pressure of about 4MPa.

[0037] 4. Mix 1g of mullite fiber and 0.5g of ceramic binder, and stir evenly to obtain a ceramic fiber mixture. On the upper surface of the active carbon laye...

Embodiment 3

[0041] 1. Same as step (1) in Embodiment 1.

[0042] 2. Weigh 10g of silicon carbide particles, 2.68g of ceramic binder, 3.45g of activated carbon (particle size 3μm) and 2.5g of carboxymethyl cellulose (CMC) solution with a mass fraction of 2wt%; first add silicon carbide particles CMC solution, and stir evenly; Then ceramic binder and activated carbon are added respectively, and after stirring until uniform, weigh its 4g mixture and dry-press molding, the pressure is about 26MPa, obtains the SiC porous ceramic support green body, The diameter is 20mm and the thickness is about 5mm. The average particle size of the silicon carbide particles is 220 μm.

[0043] 3. Scatter and spread a layer of activated carbon powder (particle size: 3μm.) on the surface of the support body, and dry press it with a pressure of about 3MPa.

[0044] 4. Mix 1g of mullite fiber and 1.2g of ceramic binder, and stir evenly to obtain a ceramic fiber mixture. On the upper surface of the activated ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com