Automatic classification dustbin based on capacitive sensor principle

A capacitive sensor, automatic classification technology, applied in trash cans, garbage collection, recycling technology and other directions, can solve problems such as unfavorable popularization and application, single function, secondary pollution, etc. A wide variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

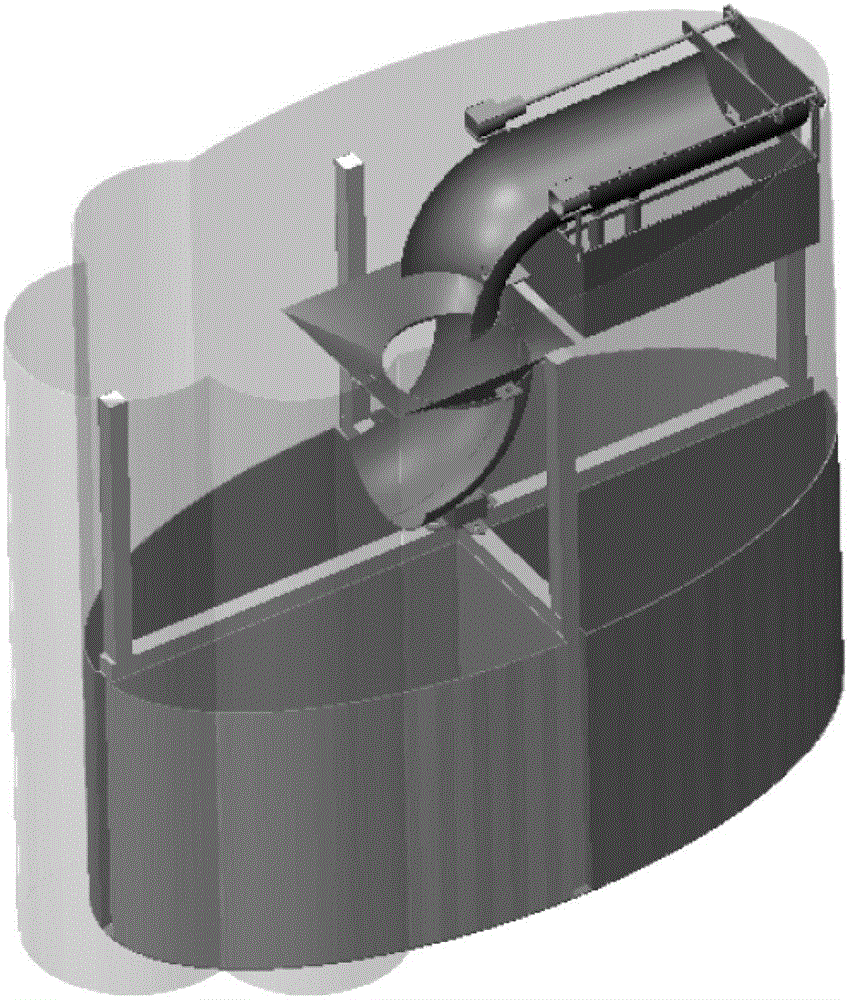

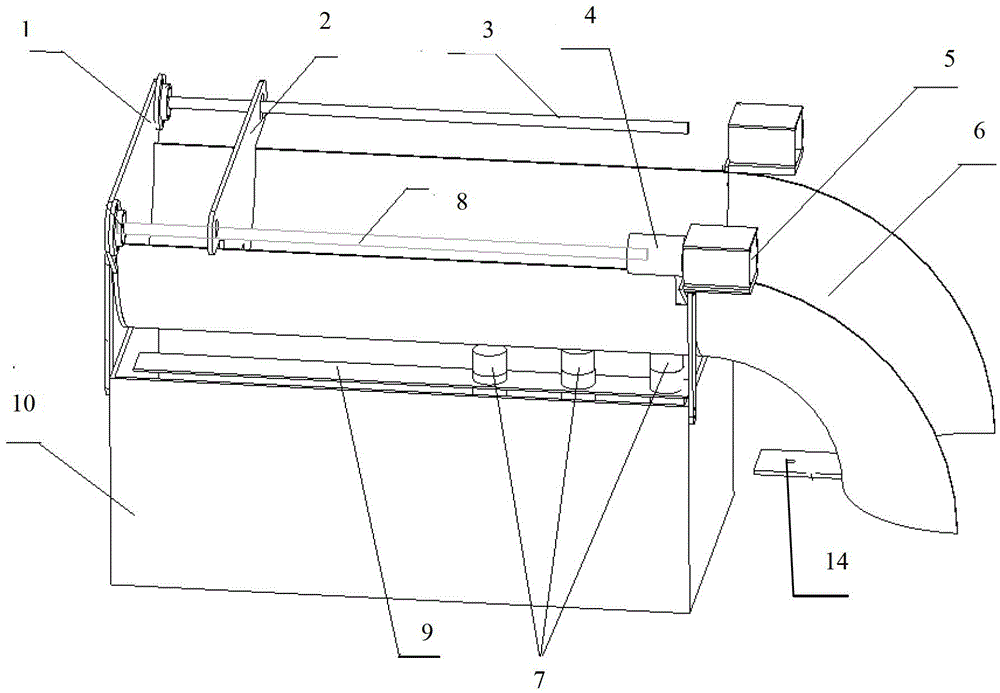

[0024] Such as Figure 2-7As shown, an automatic sorting garbage bin based on the principle of capacitive sensors includes a detection device, a classification device, a recovery device, a support device, and a casing, wherein: the detection device includes a slideway 6, and the end of the slideway 6 is not closed , and bend downwards, the starting end is fixed with a baffle plate 1, and a pushing device that pushes the object on the slideway forward is installed on the said baffle plate 1, and said pushing device includes a screw rod 8 arranged along the said slideway One end of the screw mandrel 8 is fixed on one side of the baffle plate through a bearing and a shaft coupling, the other end is connected with the motor 5, and the motor drives the screw mandrel 8 to rotate, and the screw mandrel is threadedly connected with a push plate 2, and the screw mandrel 8. The rotation drives the push plate 2 to move along the slideway 6, pushing the garbage to the end of the slideway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com