Rubber block chopping machine

A shredder and rubber glue technology, which is applied in the field of machinery, can solve the problems of high energy consumption, low production efficiency, and poor quality of the tire manufacturing industry in the production process, and achieve uniform particle size and smoothness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

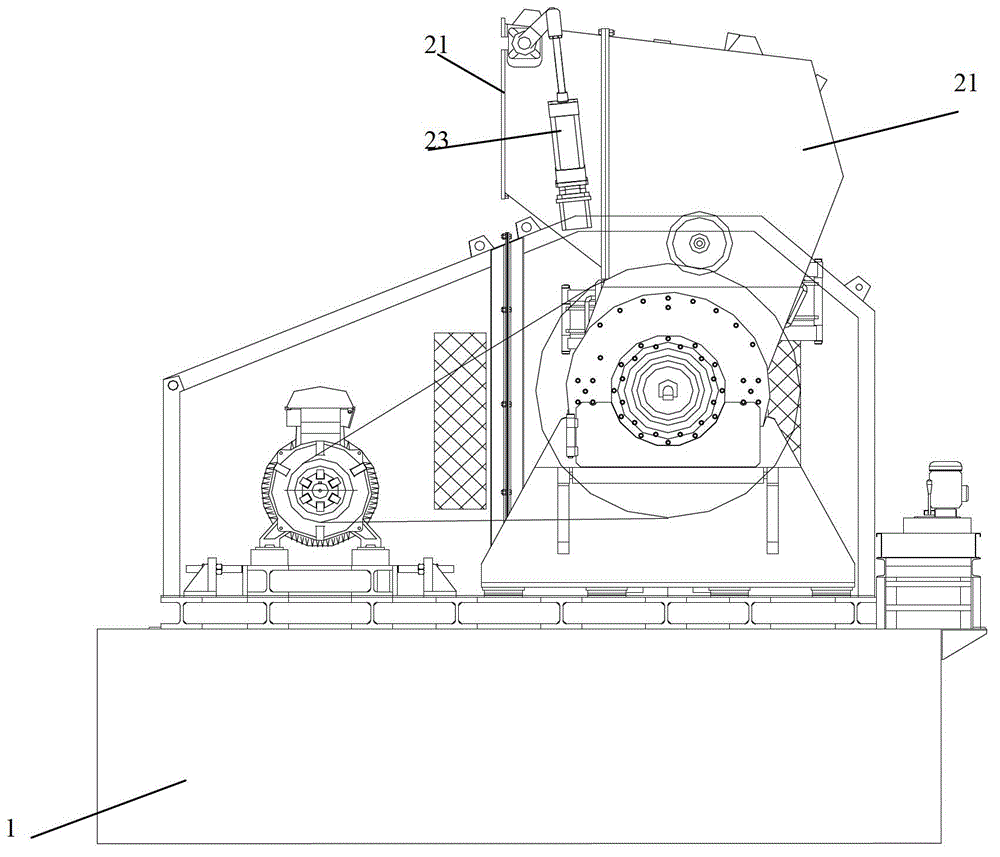

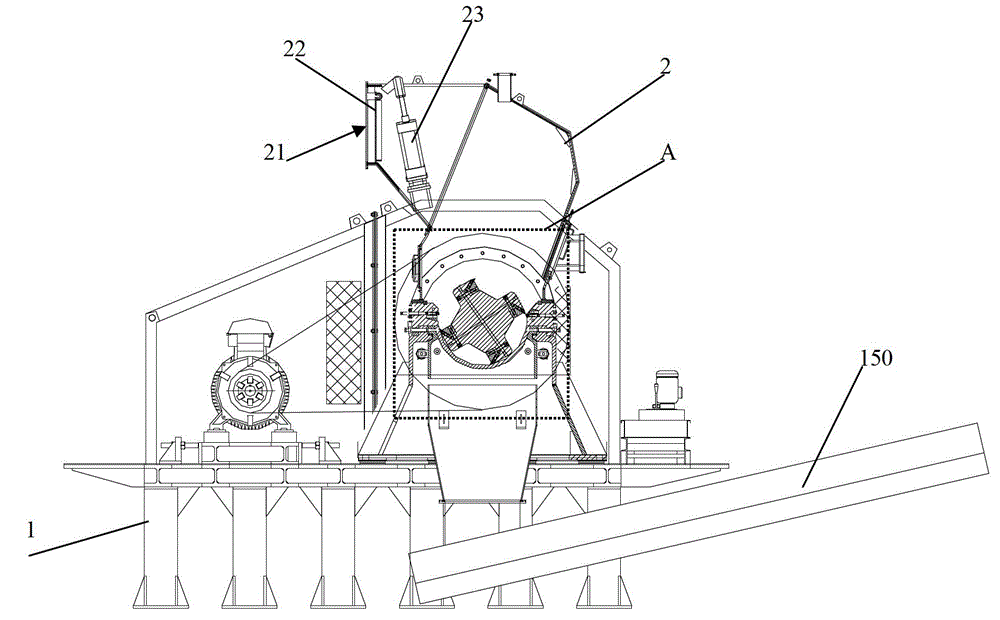

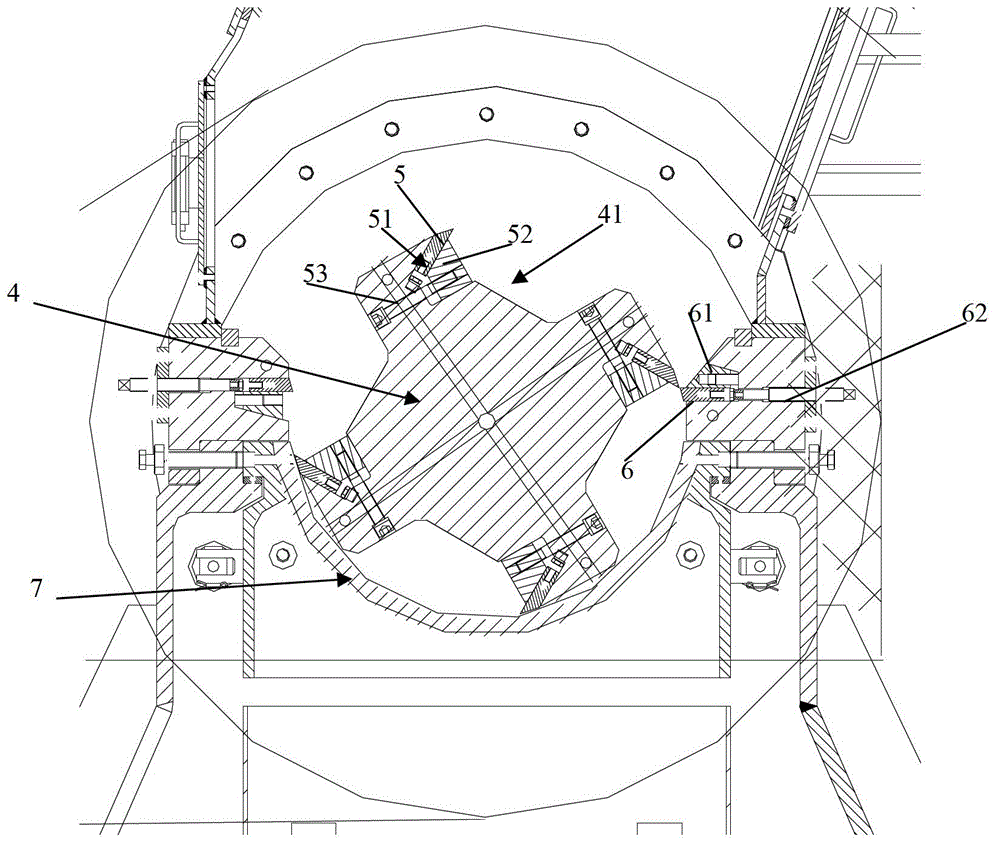

[0027] Such as Figure 1-5 As shown, the rubber block shredder of the present invention includes a frame 1, a feed hopper 2, a chopping device and a discharge device, and the release agent spraying that can spray the release agent in the feed hopper and the discharge device respectively device, the chopping device includes a chopping chamber 3, a main shaft 4 rotatably arranged in the cutting chamber, a plurality of moving knives 5 fixedly arranged on the main shaft, fixedly arranged in the cutting chamber and located on both sides of the main shaft and A fixed knife 6 keeping a set distance from the moving knife, and an arc-shaped screen 7 arranged at the lower part of the chopping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com